Understanding Chemical Stability in Tungsten Carbide Tools

Tungsten carbide tools are widely recognized for their exceptional hardness and wear resistance—but there’s another property that’s just as vital for long-term performance: chemical stability. Whether operating in corrosive environments, exposed to coolants, or enduring high-temperature reactions, carbide tools must resist chemical degradation to maintain their functionality. This article explains what chemical stability means, why […]

Understanding Carbide Composition in Tungsten Carbide Tools

Tungsten carbide tools are valued for their extreme hardness, high wear resistance, and long service life—but what makes these properties possible? The answer lies in their carbide composition. This term refers to the specific combination of materials used to form the tool, which directly influences its mechanical, chemical, and thermal performance. This article will explain […]

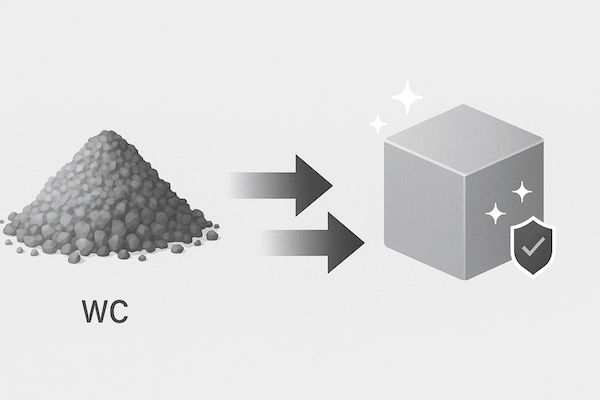

Understanding Carbide Powder in Tungsten Carbide Tool Manufacturing

When we think of cutting tools, mining bits, or industrial wear parts, we often picture strong, solid, high-performance components. But the origins of these incredibly tough tools actually begin with something much finer: carbide powder. In this article, we’ll explore what carbide powder is, how it’s produced, and why it’s so critical to the manufacturing […]

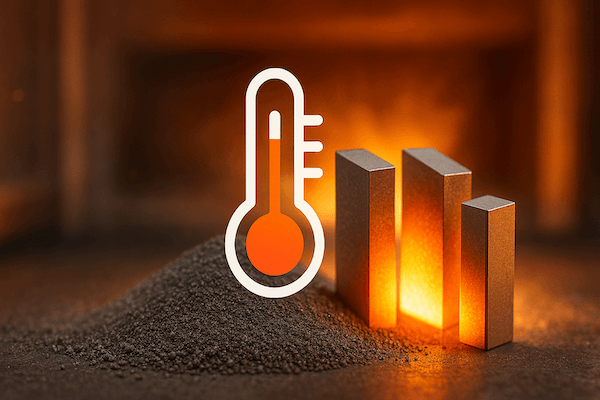

Understanding Sintering Temperature in Tungsten Carbide Tool Manufacturing

Sintering temperature is a critical factor in the production of tungsten carbide (WC) tools, directly influencing their hardness, strength, microstructure, and overall performance. In this article, we’ll explore what sintering temperature means, its role in hard alloy production, and why precise control is essential for producing high-quality carbide tools. https://www.retopz.com/wp-content/uploads/2025/06/Understanding-Sintering-Temperature-in-Tungsten-Carbide-Tool-Manufacturing.png What Is Sintering Temperature? Sintering […]

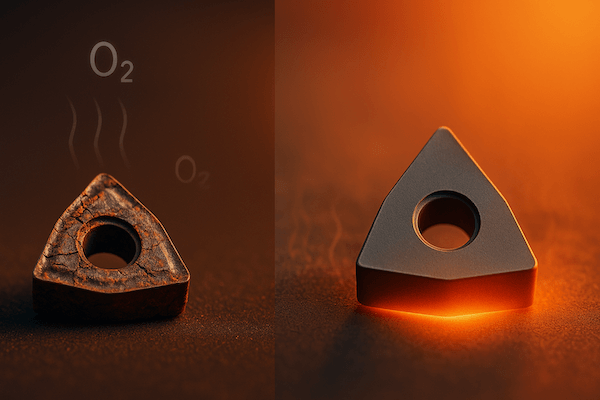

Understanding Oxidation Resistance in Tungsten Carbide Tools

In the world of advanced materials, oxidation resistance is a critical property that defines how well a material can withstand chemical reactions with oxygen at elevated temperatures. For tungsten carbide (WC) tools, oxidation resistance plays a key role in determining tool life, surface stability, and suitability for high-temperature industrial applications. In this article, we’ll explore […]

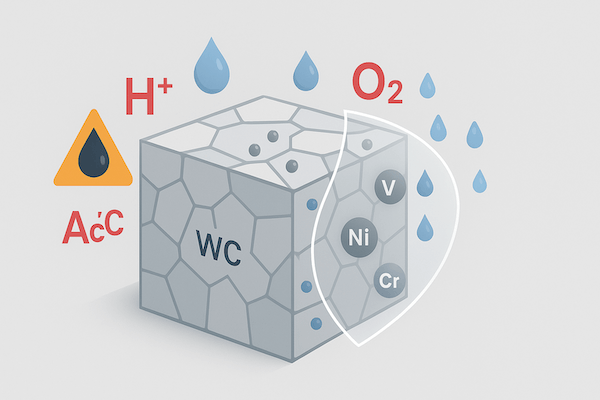

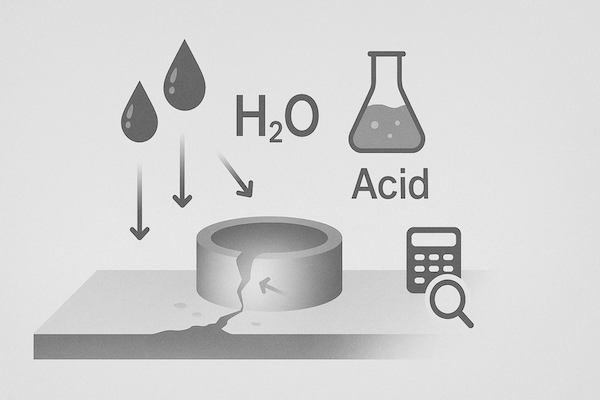

Understanding Corrosion Resistance in Tungsten Carbide Tools

What is Corrosion Resistance? Corrosion resistance refers to a material’s ability to withstand chemical degradation caused by interactions with its environment—such as moisture, acids, alkalis, salts, or gases. Corrosion typically leads to oxidation, pitting, surface erosion, and eventual weakening of the material’s structure. Materials with high corrosion resistance maintain their mechanical integrity, dimensional stability, and […]

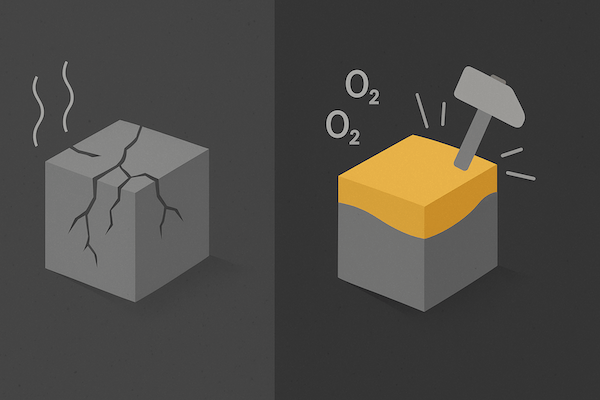

Understanding Binder Material in Tungsten Carbide Tools

In the world of advanced materials, binder material is one of the most critical components in the production of tungsten carbide (WC) tools. Although tungsten carbide itself is known for its exceptional hardness and wear resistance, it is the binder material that gives these tools their toughness, durability, and structural integrity. This article explores what […]

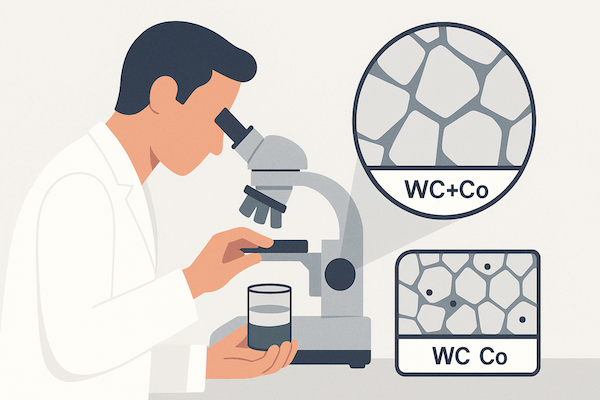

Understanding Metallography in Tungsten Carbide Tools

Metallography is a scientific method used to study the microstructure of metals and alloys, and it plays a vital role in the development, quality assurance, and failure analysis of tungsten carbide tools. In the field of cemented carbides, metallography provides essential insight into grain size, phase distribution, porosity, and binder integrity—all of which directly affect […]

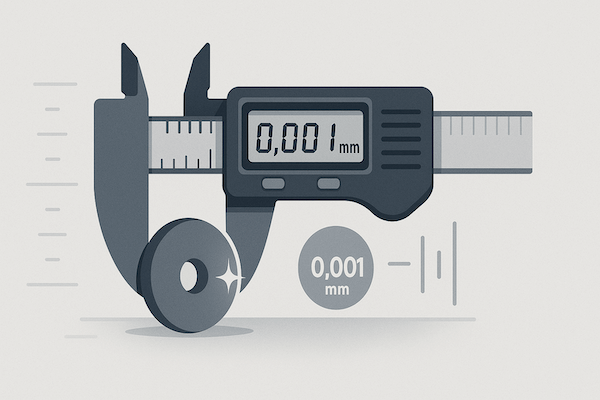

Understanding Precision Measurement in Tungsten Carbide Tools

Precision measurement is a cornerstone of modern manufacturing, especially in the production and quality control of tungsten carbide tools. As one of the hardest and most wear-resistant materials, tungsten carbide (WC) is used in industries where tight tolerances, dimensional accuracy, and surface integrity are non-negotiable. In this article, we explore what precision measurement is, why […]

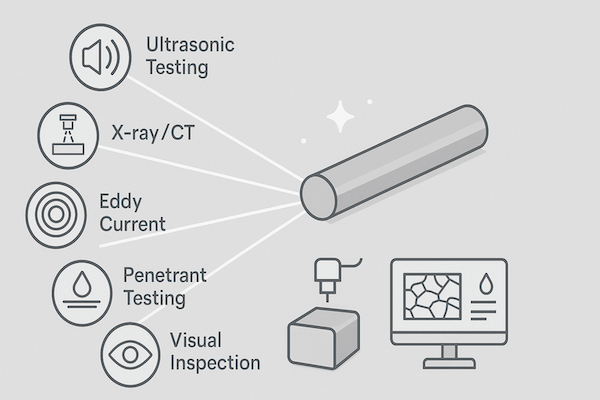

Understanding Non-Destructive Testing in Tungsten Carbide Tools

Non-Destructive Testing (NDT) is a critical quality assurance method used to evaluate the internal and surface integrity of materials and components—without causing damage. In the world of tungsten carbide tools, where reliability, performance, and precision are paramount, NDT plays a key role in ensuring that each part meets stringent quality and safety standards. What Is […]

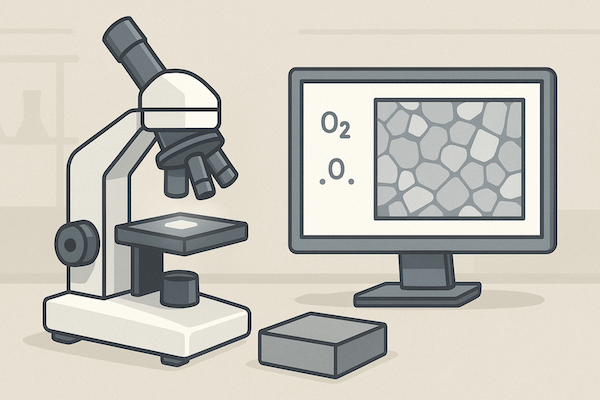

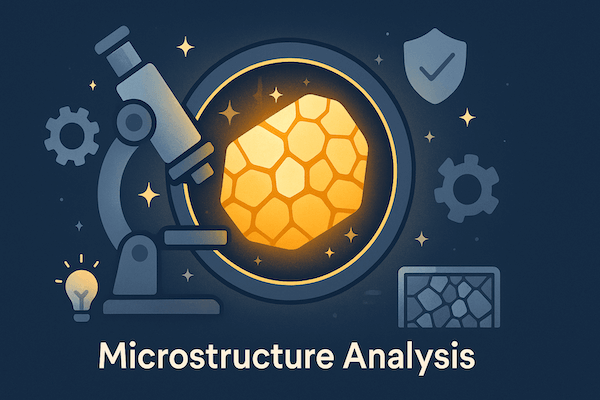

Understanding Microstructure Analysis in Tungsten Carbide Tools

Microstructure analysis is a key technique in materials science that enables the in-depth study of internal structures in metals and composites. For tungsten carbide tools—which are widely used in cutting, mining, wear-resistant, and precision applications—microstructure analysis plays a central role in quality control, performance optimization, and failure prevention. What Is Microstructure Analysis? Microstructure analysis refers […]

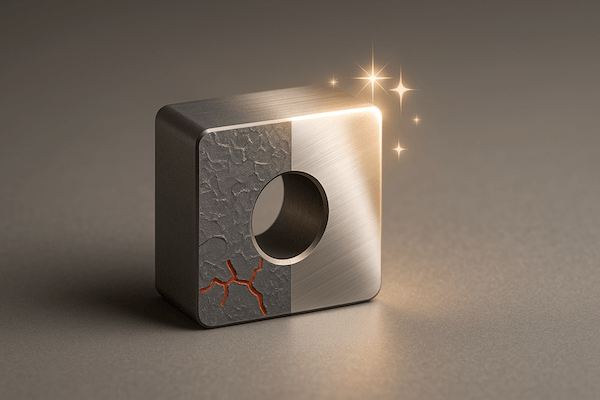

Understanding Surface Finish in Tungsten Carbide Tools

In high-performance industrial tools, especially those made from tungsten carbide, surface finish is not just a cosmetic attribute—it is a key technical factor that directly affects tool performance, longevity, and application compatibility. This article explores what surface finish means, why it matters for cemented carbide tools, how it’s measured, and how it’s optimized in manufacturing. […]

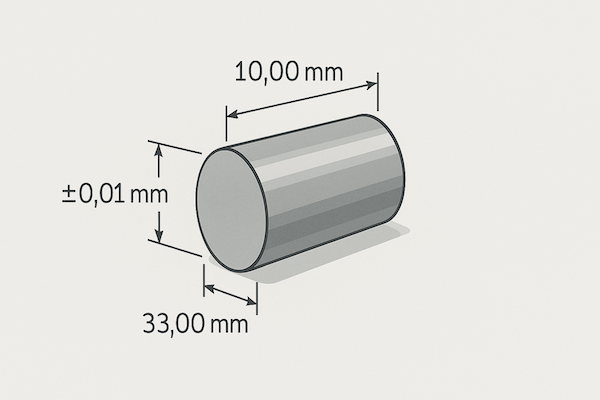

Understanding Dimensional Tolerance in Tungsten Carbide Tools

What is Dimensional Tolerance? Dimensional tolerance refers to the permissible limit or limits of variation in a physical dimension—such as length, diameter, or thickness—of a manufactured part. It defines how much deviation is acceptable from the nominal dimension without compromising the function or interchangeability of the part. For example, a carbide rod with a nominal […]