Thermal Stability in the Tungsten Carbide Industry: An Explanatory Overview

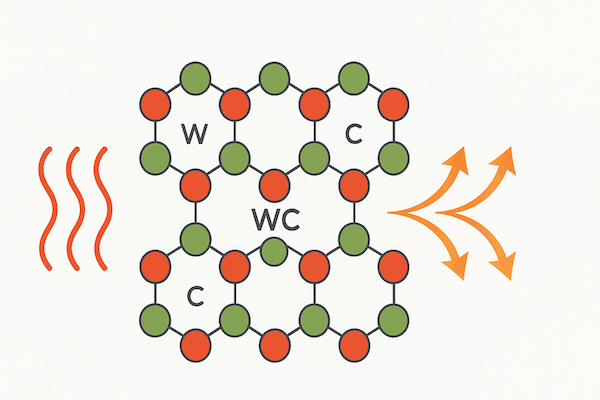

Introduction In the realm of advanced materials, tungsten carbide (WC) stands out for its exceptional hardness, wear resistance, and high melting point. These properties make it indispensable in a variety of industries, including mining, aerospace, manufacturing, and automotive sectors. Among its numerous advantageous characteristics, thermal stability is a pivotal property that significantly influences the performance […]

Porosity in the Tungsten Carbide Industry: An Explanatory Overview

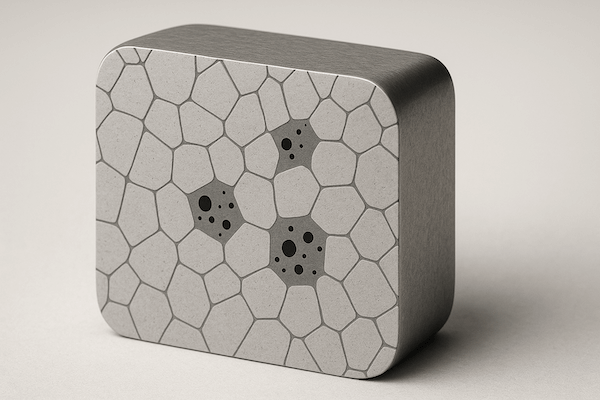

Introduction Porosity is a critical concept in materials science, especially when it comes to high-performance materials like tungsten carbide (WC) used in industrial tools. Though often overlooked, porosity plays a significant role in determining the mechanical strength, wear resistance, and overall reliability of carbide tools. This article breaks down what porosity is, how it forms, […]

Understanding Grain Size in Tungsten Carbide Tools

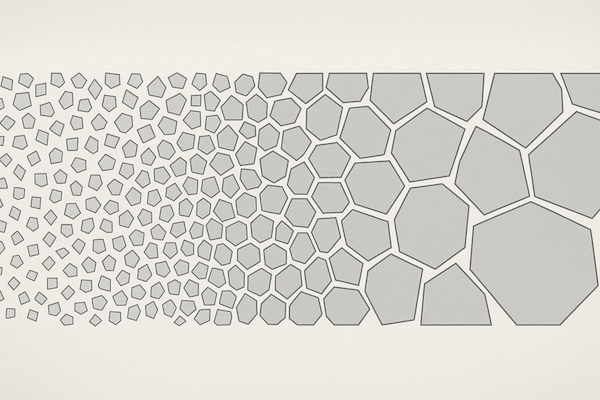

In the world of advanced materials and tooling, one term that frequently arises is “grain size.” While it might sound like a detail only metallurgists care about, grain size plays a critical role in the performance, strength, and durability of tungsten carbide tools used across mining, machining, oil & gas, and precision manufacturing industries. So—what […]

Understanding Alloying Elements in Tungsten Carbide Tools

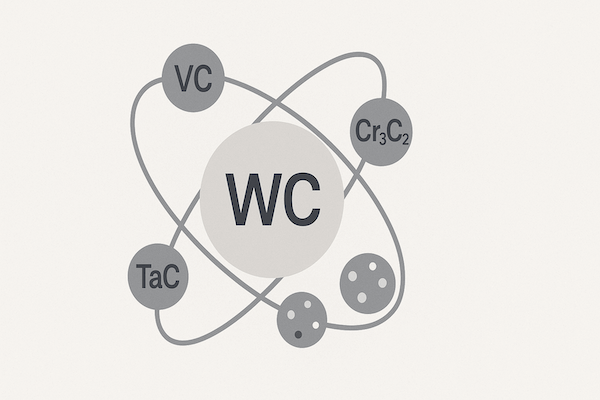

Tungsten carbide tools are renowned for their exceptional hardness, wear resistance, and ability to withstand extreme working conditions. But behind this impressive performance lies more than just WC and cobalt—it’s also the result of carefully selected alloying elements. These trace additions may be small in quantity, but they have a big impact on tool behavior, […]