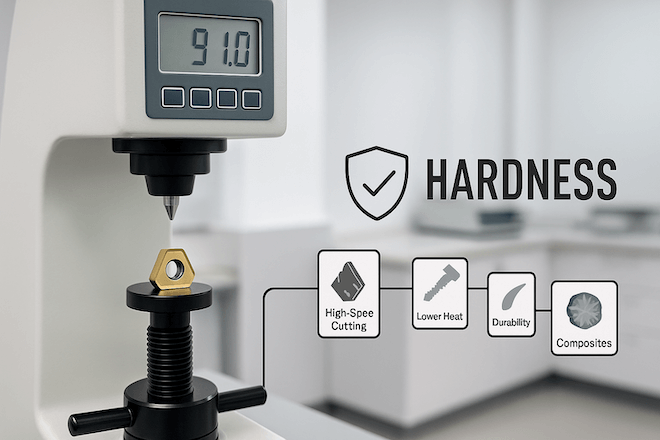

How to Identify Quality Tungsten Carbide Cutting Tools

Tungsten carbide cutting tools are used in many industries because they are hard, durable, and long-lasting. But not all carbide tools are the same. Poor-quality tools can wear out quickly, break, or give a poor finish. This guide will help you understand how to check the quality of tungsten carbide cutting tools before buying or […]

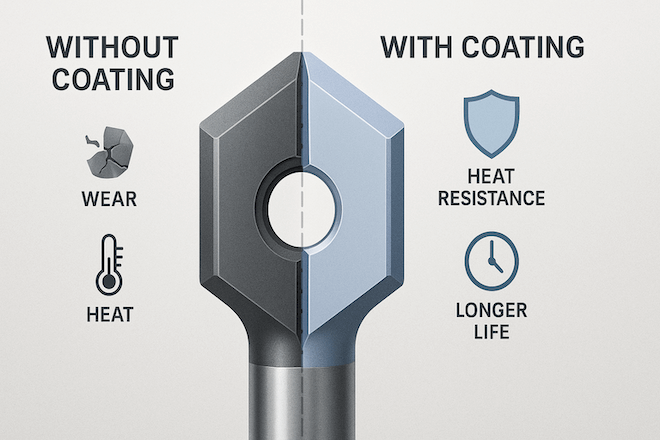

The Role of Coatings in Enhancing Tungsten Carbide Cutting Tool Performance

Tungsten carbide cutting tools are widely used in industries like metalworking, woodworking, aerospace, and mold manufacturing. They are strong, wear-resistant, and can cut hard materials. But even these tools can wear out or break over time. This is where tool coatings come in. A good coating helps extend the tool’s life, improve performance, and reduce […]

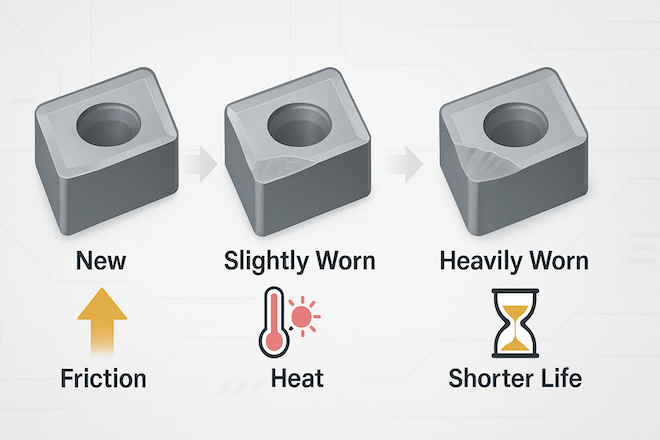

Common Problems and Solutions with Tungsten Carbide Cutting Tools

Tungsten carbide cutting tools are known for their strength, hardness, and long life. But even these high-performance tools can face problems during use. Understanding the common issues and knowing how to fix them can help you improve tool life, reduce waste, and keep your operations running smoothly. In this blog, we’ll explore the most common […]