How to Sharpen and Recondition Tungsten Carbide Cutting Tools

Tungsten carbide cutting tools are known for their incredible durability and long-lasting edge retention. However, even the strongest tools wear down with regular use. Instead of replacing dull tools every time, you can often sharpen or recondition them to restore their performance and extend their life. This not only saves money, but also helps maintain […]

Maintenance Tips for Extending the Life of Your Tungsten Carbide Cutting Tools

Tungsten carbide cutting tools are known for their strength, durability, and wear resistance. But even the toughest tools won’t last forever without proper care. If you want to get the most out of your carbide tooling—and avoid wasting time and money—you need the right maintenance habits. This guide breaks down simple, practical tips to extend […]

Why Tungsten Carbide Cutting Tools Have Superior Wear Resistance

In modern machining, tool wear is one of the biggest challenges. When tools wear out too fast, it leads to poor finishes, slower production, and higher costs. That’s why wear resistance matters—and this is where tungsten carbide cutting tools truly shine. Tungsten carbide is not just another tool material. It’s one of the hardest and […]

Understanding Tungsten Carbide Grades for Cutting Tool Applications

When it comes to cutting tools, tungsten carbide is the go-to material for professionals who need strength, speed, and reliability. But not all carbide tools are created equal. The grade of tungsten carbide you choose can greatly affect how your tool performs—and how long it lasts. Whether you’re cutting aluminum, steel, or composites, using the […]

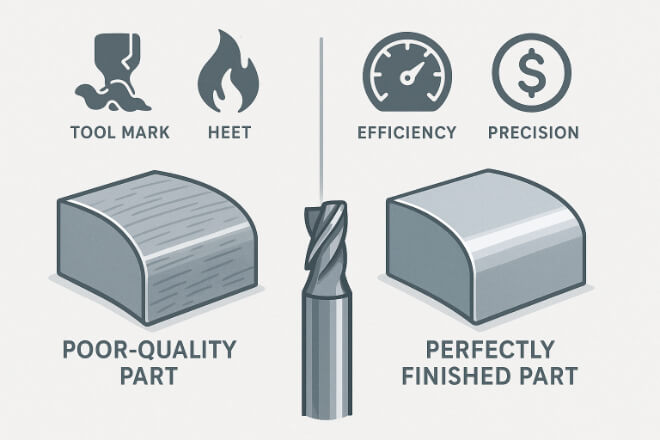

How Tungsten Carbide Cutting Tools Improve Machining Efficiency and Precision

In modern machining, speed and accuracy are everything. Whether you’re producing parts in a CNC workshop or managing large-scale manufacturing, the quality of your cutting tools directly affects your output, costs, and product quality. That’s why more industries are switching from traditional tools to tungsten carbide cutting tools. But what makes them so special? And […]

Top Applications of Tungsten Carbide Cutting Tools Across Industries

Tungsten carbide cutting tools are known for being super hard, very durable, and excellent at keeping a sharp edge. These tools are used in many industries—from aerospace to woodworking—because they can handle tough jobs that regular steel tools can’t. In this article, we’ll explore the top industries using tungsten carbide cutting tools, why these tools […]

Tungsten Carbide vs High-Speed Steel: Which Cutting Tool Is Better?

When it comes to cutting tools, two materials come up again and again: tungsten carbide and high-speed steel (HSS). If you’re wondering which one is better for your work, the answer depends on what you value more—speed, durability, or budget. But if you want long-lasting tools, better performance, and faster machining—tungsten carbide is the clear […]

How to Choose the Right Tungsten Carbide Cutting Tool for Your Application

Tungsten carbide cutting tools are strong, fast, and dependable—but picking the right one isn’t always easy. With so many types, coatings, and uses, it’s normal to feel overwhelmed, especially if you’re not a tooling expert. In this beginner-friendly guide, we’ll show you exactly how to choose the right tungsten carbide cutting tool for your job. […]

Benefits of Using Tungsten Carbide Cutting Tools in CNC Machining

In CNC machining, precision and productivity matter. Whether you’re producing a single high-precision part or running a full production line, your cutting tools play a huge role. One material stands out from the rest: tungsten carbide. More and more machine shops and manufacturers are switching to tungsten carbide cutting tools—and for good reason. These tools […]

What Are Tungsten Carbide Cutting Tools? A Complete Beginner’s Guide

In today’s fast-moving manufacturing world, cutting tools need to be strong, precise, and long-lasting. That’s where tungsten carbide cutting tools come in. These tools are used in nearly every industry—automotive, aerospace, construction, oil & gas, and more—because they can cut through the toughest materials with ease. If you are new to machining or simply curious […]