The Role of Tungsten Carbide Cutting Tools in High-Speed Machining

In today’s competitive manufacturing world, speed is everything. Companies need to produce high-quality parts faster, with less downtime and waste. That’s where high-speed machining (HSM) comes in—a process that uses faster cutting speeds and feed rates to boost productivity. But there’s a catch: not every tool can survive under such demanding conditions. This is where […]

Differences Between Uncoated and Coated Tungsten Carbide Cutting Tools

Tungsten carbide cutting tools are trusted in industries like aerospace, automotive, mold-making, and precision machining. Their strength, wear resistance, and cutting speed make them essential. But when it comes to choosing between uncoated and coated versions, many decision-makers in machining businesses find themselves unsure. This guide explains the real differences between uncoated and coated tungsten […]

How to Store Tungsten Carbide Cutting Tools Properly

Tungsten carbide cutting tools are known for their strength, hardness, and long life. These tools can handle tough jobs and keep working under high heat and pressure. But even the strongest tools need proper care—especially when they’re not in use. Improper storage can lead to rust, damage, chipping, or loss of performance over time. In […]

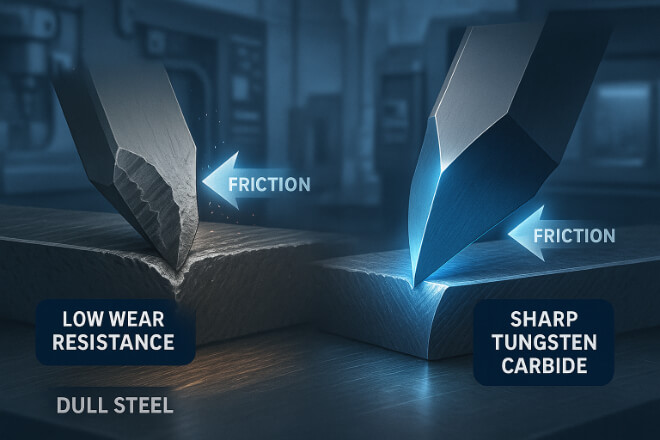

The Science Behind Tungsten Carbide Cutting Tool Wear Resistance

When it comes to machining hard materials or running long production cycles, tungsten carbide cutting tools are often the first choice. These tools are known for their exceptional wear resistance, but what exactly gives them that strength? In this article, we’ll break down the science behind why tungsten carbide tools last longer, resist damage, and […]

Innovations in Tungsten Carbide Cutting Tool Design and Materials

In today’s competitive manufacturing environment, we are always looking for ways to cut faster, last longer, and produce better-quality parts. Tungsten carbide cutting tools have already earned their place as a go-to solution for high-performance machining. But the innovation hasn’t stopped. In recent years, there have been exciting advances in tungsten carbide tool design and […]

The Manufacturing Process of Tungsten Carbide Cutting Tools Explained

Tungsten carbide cutting tools are known for their strength, durability, and ability to cut even the toughest materials. But how are these tools made? Many people use carbide tools daily in machining, but few understand the complex and fascinating process behind their creation. In this article, we’ll break down the complete manufacturing process of tungsten […]

Understanding the Hardness and Toughness Balance in Tungsten Carbide Cutting Tools

Tungsten carbide cutting tools are widely used in machining industries because they are hard, durable, and perform well under tough conditions. But one important factor that often gets overlooked is the balance between hardness and toughness. Getting this balance right can make the difference between a tool that breaks too easily and one that delivers […]

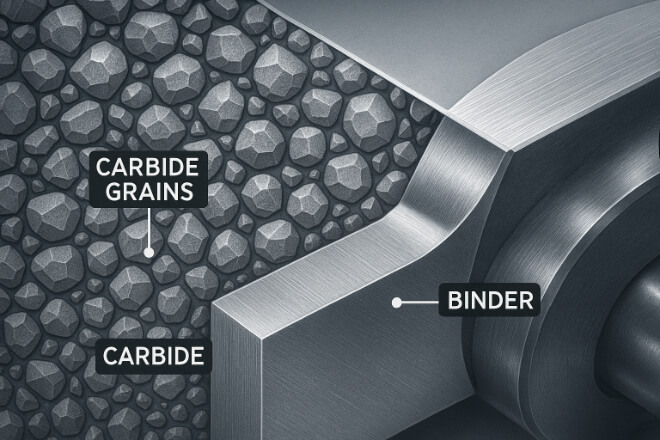

How Tungsten Carbide Microstructure Affects Cutting Tool Performance

Tungsten carbide cutting tools are essential in modern manufacturing. They are known for being hard, tough, and reliable in high-speed machining. But not many decision-makers take time to understand what makes these tools perform so well. One key factor is microstructure—the tiny internal structure of the tungsten carbide material. In this article, we’ll explain what […]

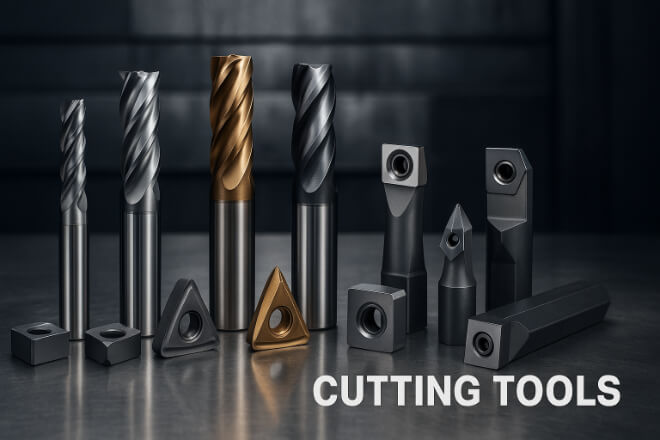

Frequently Asked Questions About Tungsten Carbide Cutting Tools

In the world of machining and manufacturing, tungsten carbide cutting tools are trusted for their strength, durability, and performance. Still, many professionals—especially decision-makers—have questions about how these tools work, when to use them, and how to get the best results. In this guide, we’ll answer the most common questions using simple, clear language. What Are […]

How to Inspect Tungsten Carbide Cutting Tools for Damage

Tungsten carbide cutting tools are widely used in machining because they’re strong, durable, and can cut hard materials with ease. But no matter how tough these tools are, they will eventually wear down or get damaged. If you don’t spot the damage early, it can lead to poor surface finish, part inaccuracy, machine issues, or […]