Emerging Technologies in Tungsten Carbide Wear Parts

Tungsten carbide has been a trusted material for wear parts for decades. Its hardness, toughness, and wear resistance make it a top choice in industries like mining, oil and gas, metal forming, and manufacturing. However, the technology behind tungsten carbide is not standing still. New developments in materials science, manufacturing processes, and coatings are changing […]

Coated vs. Uncoated Tungsten Carbide: Which One Should You Use?

Tungsten carbide is one of the most common materials used for cutting tools, wear parts, and industrial components. It is valued for its hardness, wear resistance, and ability to keep performance under heat. However, not all tungsten carbide parts are the same. Some are coated, and others are uncoated. The coating can change how the […]

Comparing Tungsten Carbide with Ceramic and Stellite Wear Parts

In industries where parts must survive heavy wear, heat, and corrosion, choosing the right material is critical. Three of the most popular materials for wear parts are tungsten carbide, ceramic, and Stellite. Each material has unique properties, strengths, and weaknesses. For decision-makers in manufacturing, mining, oil and gas, and other heavy industries, the choice between […]

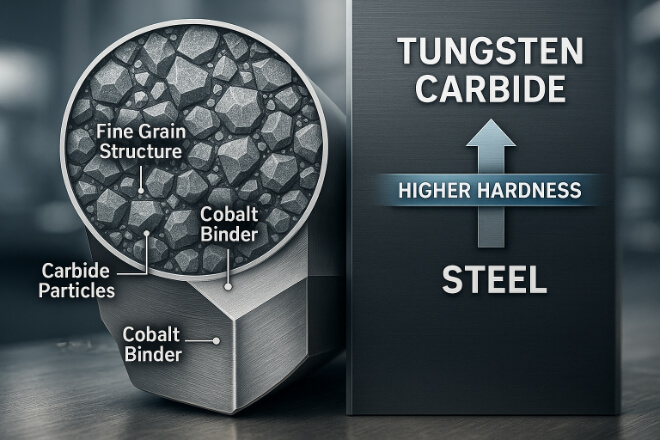

Tungsten Carbide vs. Steel: Which Wear Material Performs Better?

In industries like mining, oil and gas, metal forming, woodworking, and manufacturing, wear-resistant materials are critical. When equipment operates in tough environments, parts must withstand friction, pressure, heat, and corrosion. Two of the most common materials for wear parts are tungsten carbide and steel. Choosing the right one can affect productivity, costs, and downtime. This […]