Quality Standards for Tungsten Carbide Wear Parts

In industries such as mining, oil and gas, metal forming, paper, packaging, and woodworking, tungsten carbide wear parts are critical for reliable performance. These parts face constant friction, heat, pressure, and impact. If quality is not consistent, the risk of downtime, high replacement cost, and machine damage increases. This is why quality standards play a […]

The Long-Term Value of Investing in Tungsten Carbide

In many industries, decision-makers face the same challenge: how to balance upfront cost with long-term value. Equipment parts wear out, machines stop working, and downtime increases cost. To solve this, many companies now turn to tungsten carbide. While the first investment may look higher compared to steel or other materials, the long-term savings and performance […]

How Carbide Wear Parts Reduce Downtime and Operational Cost

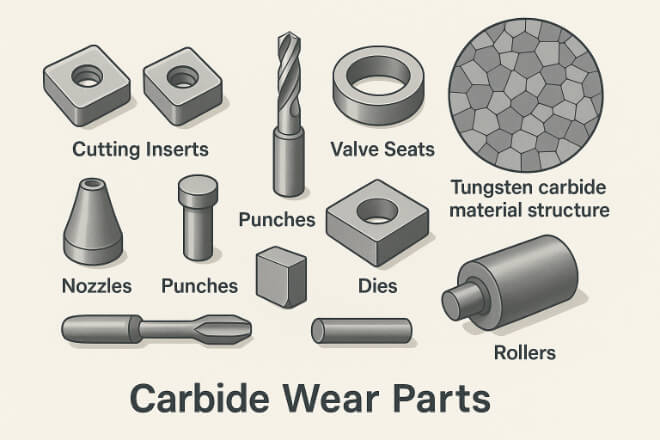

In today’s competitive industrial world, every decision-maker is under pressure to improve efficiency, reduce downtime, and cut operational cost. Machines and equipment are the heart of production, and when they fail, the company loses not only money but also time and market opportunities. One of the smartest investments industries can make is in carbide wear […]

Are Tungsten Carbide Wear Parts Environmentally Friendly?

In today’s industrial world, decision-makers face not only performance and cost challenges but also environmental responsibility. Many industries—from mining and oil & gas to metal forming and woodworking—depend on tungsten carbide wear parts. These parts are known for their hardness, long life, and wear resistance. But one important question is becoming more common: Are tungsten […]

Additive Manufacturing and Tungsten Carbide: What’s the Future?

The use of tungsten carbide wear parts is critical in many industries such as mining, oil and gas, metal forming, and manufacturing. Known for its hardness, toughness, and long life, tungsten carbide is often chosen when steel or other alloys cannot handle the extreme stress of cutting, grinding, or wear. At the same time, additive […]

The Role of Coatings in Enhancing Carbide Wear Performance

Carbide wear parts are used in industries like mining, metal forming, oil and gas, and manufacturing because of their hardness and durability. However, even carbide has limits. In extreme environments—high temperatures, heavy abrasion, or corrosive conditions—uncoated carbide can wear out faster. This is where coatings come in. A high-quality coating can extend the life of […]