Best Practices for Using Tungsten Carbide Balls in High-Stress Environments

In many industries, from mining to aerospace, high-stress conditions are part of daily operations. Equipment faces extreme pressure, heat, and wear. To keep production reliable, decision-makers need materials that can handle these challenges. Tungsten carbide balls have become a go-to solution because of their hardness, wear resistance, and ability to perform where steel or ceramics […]

Tungsten Carbide Balls in Grinding and Milling Media

In modern manufacturing, mining, and material processing, grinding and milling are vital steps. The tools used in these processes directly affect product quality, production cost, and efficiency. Among the different types of grinding media, tungsten carbide balls stand out for their strength, hardness, and wear resistance. This article explains what makes tungsten carbide balls so […]

Industrial Applications of Tungsten Carbide Balls: Bearings, Valves, Ball Screws

Tungsten carbide balls are small components with a big impact in modern industry. Known for their hardness, strength, and wear resistance, they are used in many types of equipment where precision and long service life are critical. From bearings that keep machines running smoothly, to valves that control flow in pipelines, to ball screws that […]

Quality Control and Tolerance Standards for Carbide Balls

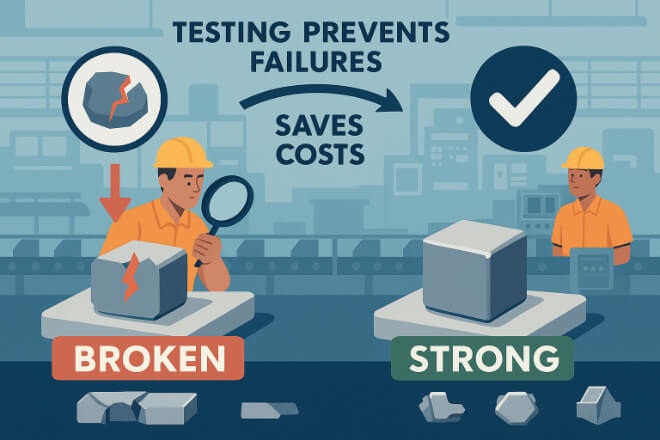

Carbide balls are small, but their role in industry is huge. They are used in valves, pumps, bearings, gauges, and many other machines where precision, hardness, and long life are required. Because of this, quality control and tolerance standards are not just technical details—they are critical for performance, safety, and cost savings. For decision-makers in […]

How to Test Tungsten Carbide

Tungsten carbide is one of the hardest and most reliable industrial materials. It is widely used in cutting tools, mining equipment, wear parts, and precision components. But before companies can trust these parts in critical operations, they need to confirm the quality, hardness, toughness, and performance of the carbide. That is where testing comes in. […]