Total Cost of Ownership: Why Tungsten Carbide Bushings Pay Off Long Term

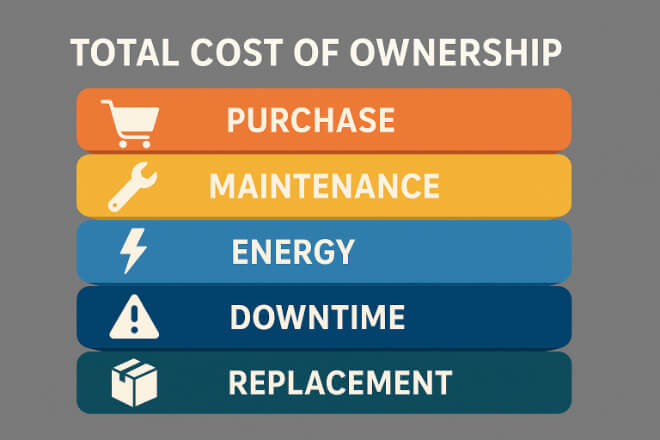

When choosing components for pumps, compressors, or turbines, many engineers focus only on the initial purchase price. But over time, the true cost is not what you pay upfront — it’s what you spend to keep your equipment running efficiently. This concept is called Total Cost of Ownership (TCO). It includes not just the purchase […]

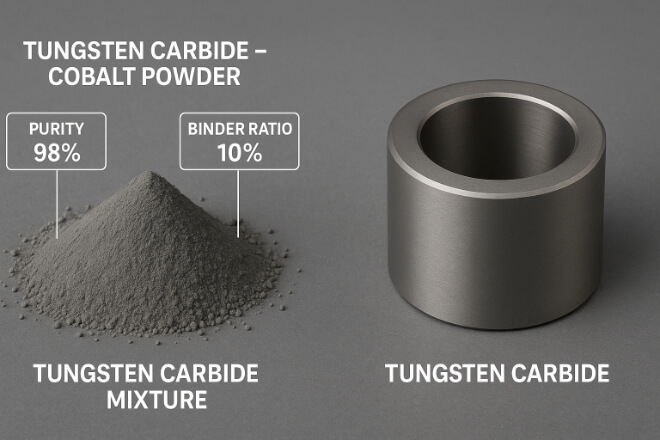

Factors Affecting the Cost of Tungsten Carbide Bushings

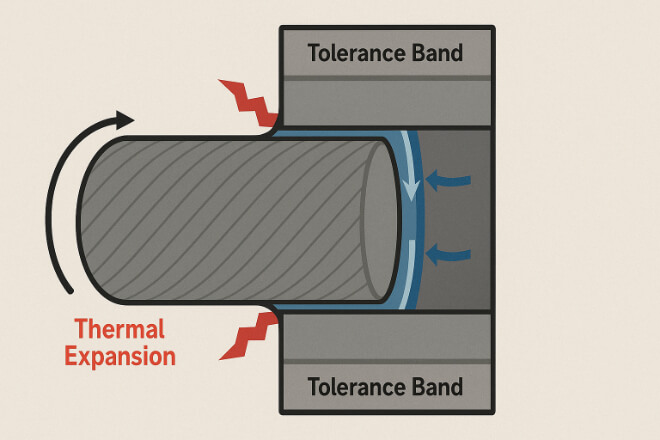

Tungsten carbide bushings are widely used in pumps, compressors, turbines, and rotating machinery. They provide exceptional wear resistance, strength, and dimensional stability under harsh conditions. However, prices for tungsten carbide bushings vary greatly from one supplier to another. Understanding what drives these costs helps buyers make smarter procurement decisions — balancing performance, reliability, and long-term […]

How to Regrind or Refurbish Tungsten Carbide Bushings

Tungsten carbide bushings are designed for extreme wear resistance and high load performance. They are widely used in pumps, compressors, turbines, and heavy-duty industrial machinery. However, after long periods of use, even carbide bushings begin to lose dimensional accuracy and surface quality. Instead of immediate replacement, regrinding or refurbishing can often restore their performance — […]

Signs It’s Time to Replace Your Tungsten Carbide Bushings

Tungsten carbide bushings are known for their exceptional wear resistance and long service life. They protect rotating shafts, maintain alignment, and reduce friction in pumps, compressors, turbines, and other mechanical systems. However, even the most durable bushing will eventually reach its wear limit. Running equipment with a damaged or worn tungsten carbide bushing can lead […]

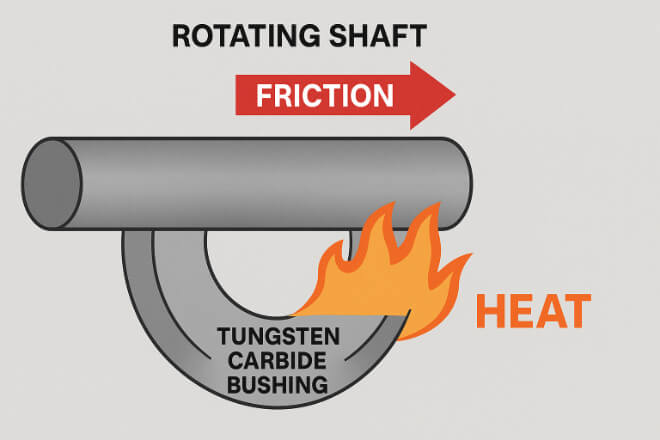

Lubrication and Cooling Best Practices for Tungsten Carbide Bushings

Tungsten carbide bushings are used in high-performance systems such as pumps, compressors, turbines, and rotating equipment. They are chosen for their hardness, wear resistance, and dimensional stability — even under heavy loads and extreme temperatures. However, their performance heavily depends on two key factors: proper lubrication and effective cooling. Without them, even the hardest material […]