In recent years, 3D printing has revolutionized many industries, particularly manufacturing.

This advanced technology allows for precision, reduced waste, and quicker production timelines.

When combined with tungsten carbide bushings, which are essential components in various machinery, the potential for innovation is vast.

This article explores how 3D printing is shaping the future of manufacturing, specifically focusing on tungsten carbide bushings.

What Are Tungsten Carbide Bushings?

Tungsten carbide bushings are components made from a hard and durable material used in various industrial applications.

They are crucial in systems requiring wear-resistant parts, such as pumps, compressors, and manufacturing equipment.

The material’s exceptional hardness and resistance to corrosion make it ideal for harsh environments.

Applications: CNC machining, oil & gas, semiconductor manufacturing

Benefits: Long lifespan, reduced downtime, enhanced efficiency

The Role of 3D Printing in Modern Manufacturing

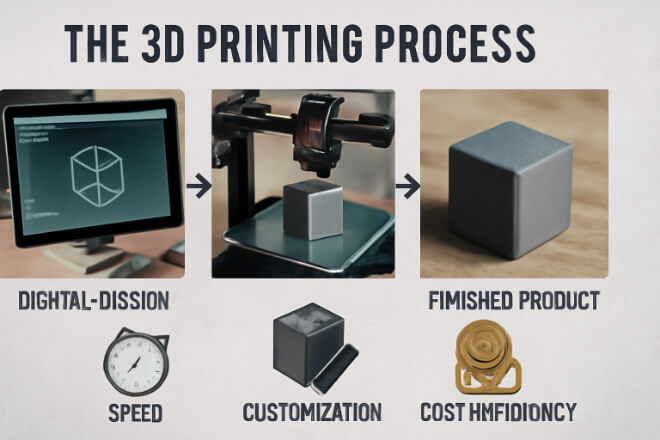

3D printing, also known as additive manufacturing, enables the creation of parts directly from a digital model.

This technology offers several advantages over traditional manufacturing methods:

Faster Production: Parts can be printed directly from CAD files, reducing the time between design and production.

Customization: Complex designs can be easily customized to fit specific needs.

Cost Reduction: For low-volume production, 3D printing can reduce costs by eliminating the need for molds or tooling.

Incorporating 3D printing into the manufacturing of tungsten carbide bushings can significantly improve efficiency and flexibility in production.

How 3D Printing Enhances Tungsten Carbide Bushings

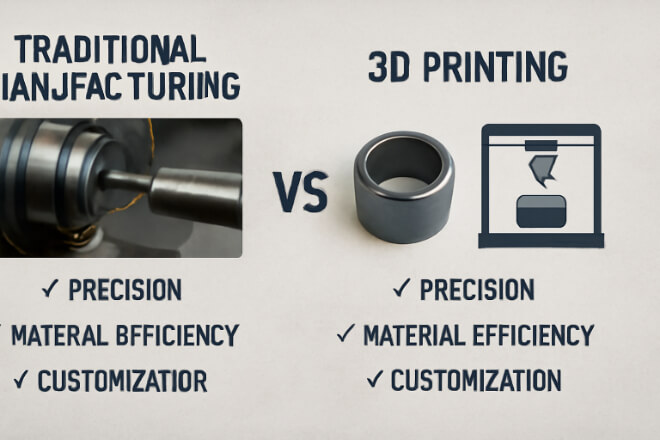

Traditionally, tungsten carbide bushings are manufactured through sintering and pressing methods. However, 3D printing introduces new possibilities:

Precision: 3D printing allows for intricate geometries that are difficult to achieve with conventional methods.

Material Efficiency: Additive manufacturing minimizes waste, as material is deposited layer by layer only where needed.

Cost-Effective Prototyping: Rapid prototyping with 3D printing enables manufacturers to test different designs before committing to mass production.

By integrating 3D printing with tungsten carbide, manufacturers can create more complex and optimized designs, resulting in better-performing bushings.

The Future of Manufacturing with 3D Printed Tungsten Carbide Bushings

As 3D printing technology advances, its application in tungsten carbide bushing manufacturing will continue to evolve. The future of manufacturing will likely see:

Increased Customization: Tailoring bushings to specific industrial needs, improving performance in specialized environments like high-pressure pumps or cryogenic systems.

Sustainability: Reduced material waste and energy consumption, leading to greener production processes.

Improved Material Properties: The ability to integrate advanced coatings or composite materials with tungsten carbide to enhance wear resistance or thermal stability.

Challenges and Considerations for 3D Printing Tungsten Carbide Bushings

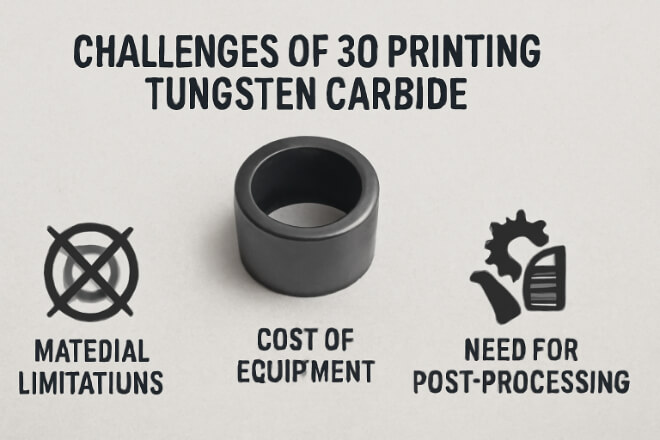

While the integration of 3D printing with tungsten carbide bushings offers significant advantages, there are challenges to consider:

Material Limitations: Printing with tungsten carbide requires specialized equipment and materials. The current capabilities of 3D printing with tungsten carbide may limit production in some industries.

Cost of Equipment: High-end 3D printing machines capable of printing with hard materials like tungsten carbide are expensive and may not be accessible to all manufacturers.

Post-Processing: Printed parts often require additional finishing processes to meet the required surface quality and dimensional accuracy.

Despite these challenges, ongoing research and development are likely to overcome these hurdles, opening the door to wider adoption in the future.

Conclusion

The future of manufacturing lies in innovation, and 3D printing is at the forefront of this transformation.

By integrating 3D printing with tungsten carbide bushings, industries can expect to see faster production, enhanced customization, and sustainable manufacturing practices.

As the technology continues to evolve, the potential for 3D-printed tungsten carbide bushings to revolutionize manufacturing processes is immense.

If you want to know more details about any company, please feel free to contact us.