Carbide balls are small, but their role in industry is huge. They are used in valves, pumps, bearings, gauges, and many other machines where precision, hardness, and long life are required.

Because of this, quality control and tolerance standards are not just technical details—they are critical for performance, safety, and cost savings.

For decision-makers in sectors like oil & gas, automotive, aerospace, and manufacturing, understanding how carbide balls are tested and certified helps in making better sourcing and purchasing choices.

This article explains the key areas of quality control for carbide balls, the tolerance standards used worldwide, and why they matter for your business.

Why Quality Control in Carbide Balls Matters

Carbide balls are expected to perform under high loads, resist corrosion, and last longer than steel balls.

If quality standards are not met, the consequences can be serious: leaking valves, inaccurate gauges, or failed bearings. Each failure means downtime, repair costs, and reputational risks.

Strong quality control ensures:

Consistency across batches.

Predictable wear life.

Lower replacement frequency.

Compliance with industry standards.

For procurement leaders, it is not only about buying carbide balls, but about ensuring reliable performance and minimized risk.

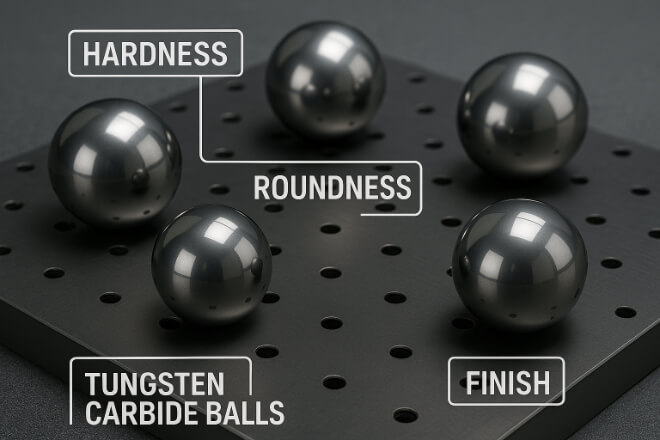

Key Quality Factors in Carbide Balls

When manufacturers talk about quality in carbide balls, they look at several factors:

Hardness: Determines wear resistance.

Roundness: Ensures smooth rolling and sealing.

Dimensional accuracy: Ensures the ball fits perfectly in its application.

Surface finish: Affects friction and sealing performance.

Each of these elements is measured using international testing standards to confirm that the product will work under tough conditions.

Tolerance Standards for Carbide Balls

Tolerance standards define how close the ball must be to its intended size and shape.

For carbide balls, tolerances are very strict because even small errors can cause equipment malfunction.

Most manufacturers follow:

ISO 3290 / DIN 5401: Defines grades of precision.

ANSI/AFBMA standards: Widely used in North America.

Tolerance covers:

Diameter variation.

Out-of-roundness.

Surface roughness.

For example, a Grade 10 carbide ball may have only a few microns of size deviation, making it suitable for high-precision bearings or gauges.

Hardness Testing of Carbide Balls

Carbide’s main strength is its hardness. To verify this, manufacturers use Rockwell hardness tests (HRA scale) or Vickers microhardness tests.

Rockwell A (HRA): Typical range for tungsten carbide balls is 88–94 HRA, depending on binder content.

Vickers: Used for smaller samples and microstructure study.

This hardness ensures resistance against wear, abrasion, and deformation. For industries like oil & gas or aerospace, this property is non-negotiable.

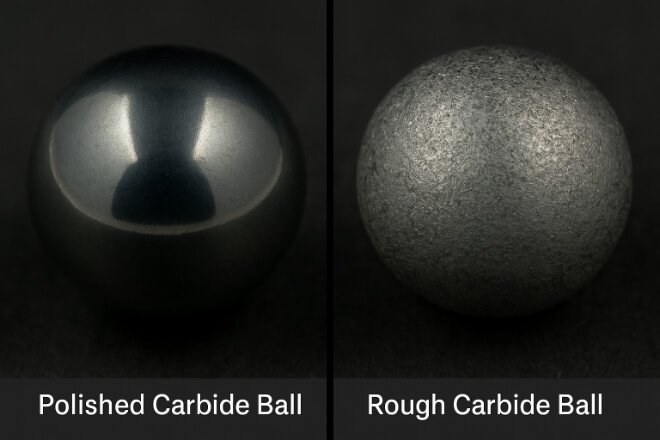

Surface Finish and Roughness Standards

Surface finish defines how smooth the ball is. A smoother ball reduces friction, improves sealing, and extends equipment life.

High-grade carbide balls have a mirror-like surface finish (Ra values in nanometers).

Lower-grade balls may still work in less demanding applications but will wear faster.

In valves or medical equipment, surface finish directly impacts product safety and efficiency.

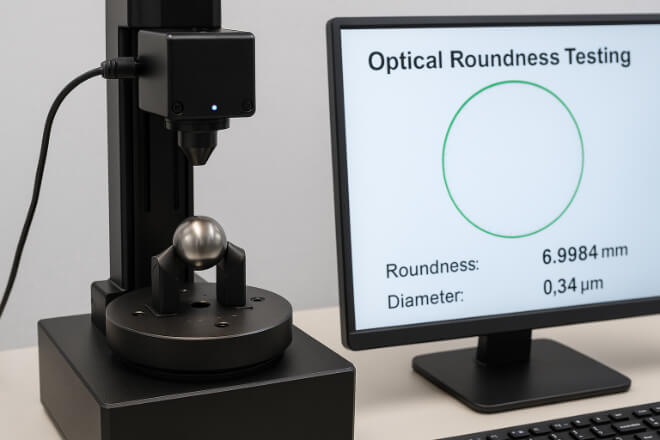

Dimensional Accuracy and Roundness Testing

Roundness is critical for rolling and sealing applications. Even small imperfections can lead to vibration, uneven wear, or leaks.

Testing involves:

Optical roundness testers.

Coordinate measuring machines (CMMs).

Laser scanning methods.

Dimensional checks also verify that balls are within microns of their target size, ensuring compatibility with precision systems.

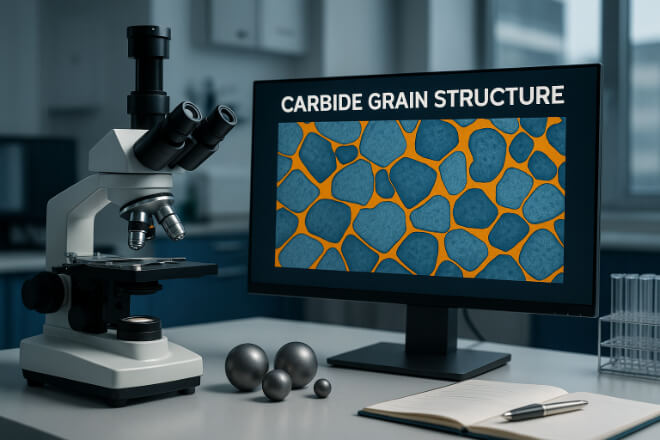

Microstructure and Density Control

Carbide balls are made of tungsten carbide grains bonded with cobalt or nickel.

The microstructure must be controlled to balance hardness and toughness.

Too coarse grains → lower strength.

Too fine grains → more brittle.

Density testing ensures no internal voids or porosity that could lead to premature failure.

Manufacturers often use X-ray or ultrasonic methods to detect hidden defects.

Common Quality Control Methods Used by Manufacturers

To ensure all standards are met, manufacturers use a combination of methods:

Visual and optical inspection.

Dimensional measurement (micrometers, CMMs).

Metallographic analysis for grain size.

Automated batch sampling with statistical process control (SPC).

Reliable manufacturers also provide inspection reports and certificates with each batch, giving buyers confidence in what they are receiving.

Industry Standards and Certifications for Carbide Balls

Procurement teams should look for suppliers who comply with international certifications. Key ones include:

ISO 9001: Quality management.

ISO 3290 / DIN 5401: Ball tolerance standards.

ASTM standards: Material and testing procedures.

These certifications show that the supplier follows global best practices and maintains traceability.

Why Decision-Makers Should Care About Tolerance Standards

For decision-makers, the question is simple: what do tolerance standards mean for the bottom line?

Better tolerance = fewer failures = lower downtime.

Consistency = predictable maintenance schedules.

Compliance = meeting customer and regulatory requirements.

Choosing carbide balls without checking tolerance standards may seem cheaper, but it can cost more in the long run.

Conclusion

Carbide balls may be small, but they carry a large responsibility in industrial performance.

Quality control and tolerance standards are not just technical language—they protect your investment, keep your machines running, and ensure product reliability.

For decision-makers, sourcing carbide balls from certified, reliable manufacturers is a strategic choice that saves money and reduces risk.

If you want to know more details about any company, please feel free to contact us.