Tungsten carbide seal rings are small but essential parts used in pumps, compressors, turbines, and other machines. They protect systems by preventing leaks and withstanding heavy stress.

To perform at their best, these rings must have a precise shape and a smooth surface. This is where grinding and polishing come in.

For decision-makers, understanding these processes is important. High-quality finishing means longer life, less maintenance, and better safety.

Poor finishing, on the other hand, can cause leaks, breakdowns, and higher costs.

This article explains the grinding and polishing processes used in tungsten carbide seal rings, why they matter, and how they bring value to industry.

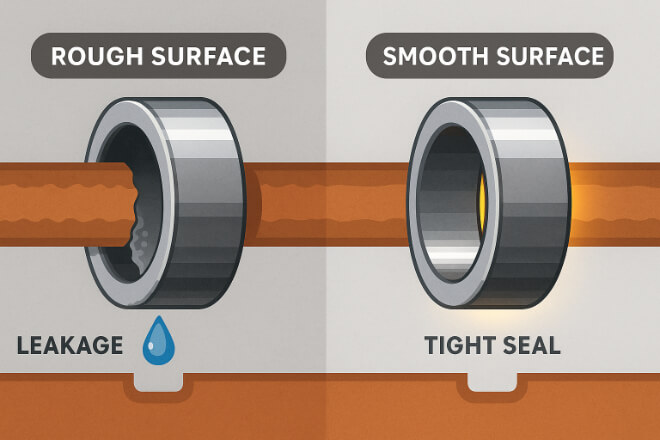

Why Surface Quality Matters in Seal Rings

Seal rings work by forming a tight contact between surfaces. If the surface is rough or uneven, problems can occur:

Leaks in pumps or compressors

Increased friction and heat

Faster wear and shorter life

Higher risk of system failure

Grinding and polishing improve the surface quality, giving the ring the right geometry and smoothness for reliable performance.

What Is Grinding in Seal Ring Production?

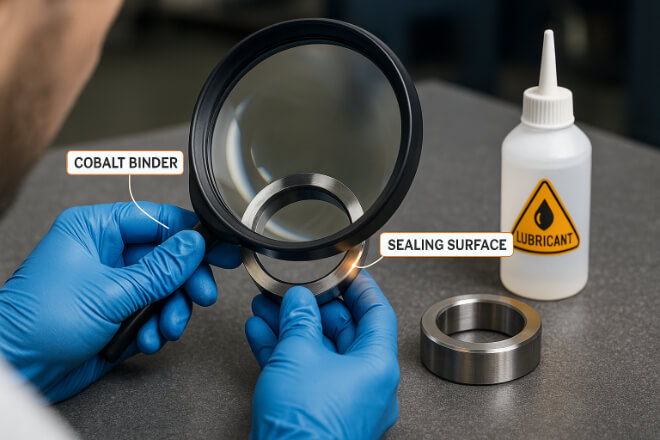

Grinding is the process of shaping and finishing tungsten carbide using abrasive tools.

Because tungsten carbide is extremely hard, grinding is done with diamond wheels or other strong abrasives.

Goals of grinding:

Achieve precise size and tolerance

Remove defects from the surface

Create flat or round shapes for sealing contact

Grinding ensures that the seal ring fits perfectly in its housing and performs well under pressure.

Grinding Techniques for Tungsten Carbide Seal Rings

1). Surface Grinding

Used to create flat sealing faces. Ensures smooth contact and uniform pressure.

2). Cylindrical Grinding

Used for the outer and inner diameters of the ring. Provides accurate dimensions.

3). Lapping

An ultra-precise grinding step that improves flatness and prepares the surface for polishing.

4). CNC Grinding

Computer-controlled grinding allows complex shapes and tighter tolerances for advanced applications.

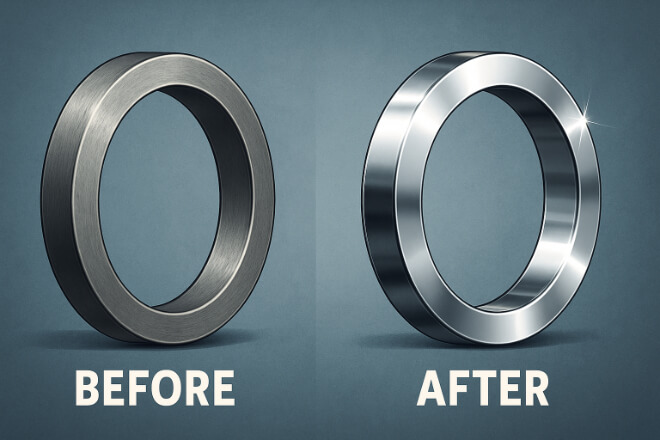

What Is Polishing in Seal Ring Production?

After grinding, the surface is smooth but may still have fine marks. Polishing removes these marks and gives the ring a mirror-like finish.

Benefits of polishing:

Lower friction between seal surfaces

Reduced heat generation

Longer service life

Improved sealing performance

Polishing is often the final step before quality inspection and packaging.

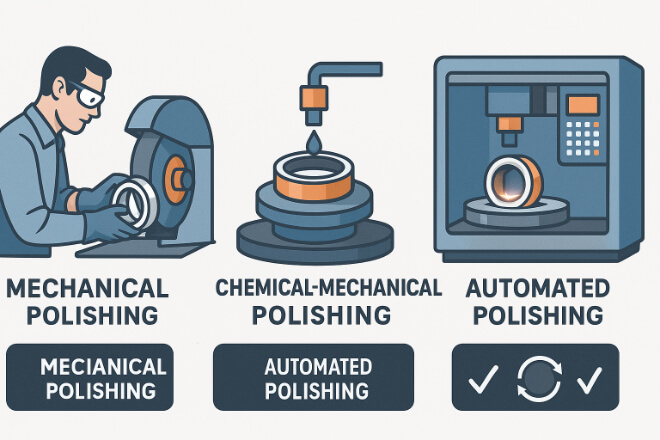

Polishing Methods for Tungsten Carbide Seal Rings

Mechanical Polishing: Uses fine abrasives and cloth wheels to achieve a smooth surface.

Chemical-Mechanical Polishing: Combines abrasives with chemicals to achieve ultra-smooth finishes.

Automated Polishing Machines: Provide consistent and repeatable results for large-scale production.

Quality Standards in Grinding and Polishing

High-performance seal rings must meet strict tolerance and surface finish standards:

Flatness within microns

Surface roughness as low as Ra 0.1 µm

Exact dimensions for proper fit

Meeting these standards ensures the rings deliver consistent sealing, even under high pressure and speed.

Why Grinding and Polishing Are Critical for Industry

For decision-makers, the value of these processes is clear:

Better Reliability: Smooth surfaces reduce leaks and breakdowns.

Lower Costs: Longer-lasting rings mean fewer replacements.

Higher Safety: Proper seals reduce the risk of accidents.

Improved Efficiency: Machines run smoother with less friction.

Comparison: Poor vs High-Quality Finishing

| Aspect | Poor Finishing | High-Quality Grinding & Polishing |

|---|---|---|

| Surface Condition | Rough, uneven, scratches | Smooth, mirror-like, defect-free |

| Seal Performance | Higher leakage risk | Tight, reliable sealing |

| Service Life | Shorter, frequent replacements | Long-lasting, fewer replacements |

| Maintenance Costs | Higher due to failures | Lower due to durability |

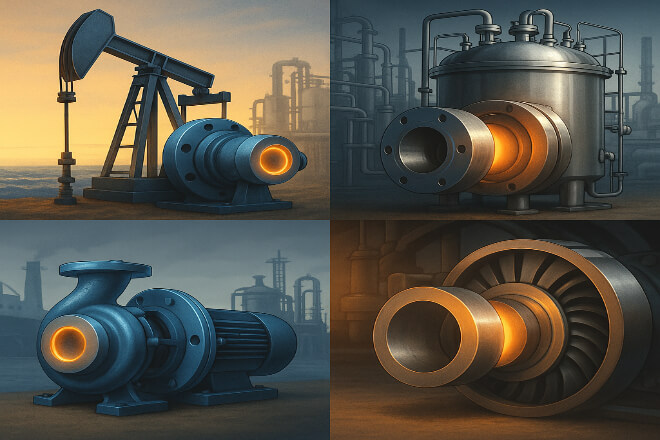

Industries That Depend on Precision Finishing

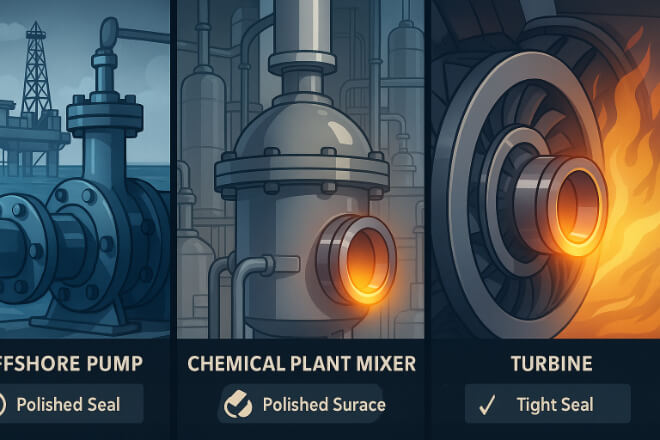

1). Oil & Gas

Seal rings face abrasive drilling mud and high pressure. Precision grinding and polishing extend service life.

2). Chemical Plants

Corrosive fluids demand tight, reliable seals. Smooth finishes prevent leaks and reduce risk.

3). Marine Industry

Seawater pumps require polished surfaces to resist corrosion and maintain sealing.

4). Power Generation

High-speed turbines need seals with low friction and high durability.

Steps in Selecting Seal Rings with Proper Finishing

Check Surface Specifications – Confirm roughness and flatness levels.

Verify Tolerance – Ensure dimensions fit the machine design.

Ask for Quality Certificates – Confirm compliance with ISO standards.

Choose Reliable Suppliers – Work with companies that specialize in grinding and polishing.

Maintenance of Polished Seal Rings

Even with high-quality finishing, maintenance is key:

Inspect for scratches or cracks regularly

Replace rings when wear reaches limits

Avoid contamination during operation

Use correct lubrication when required

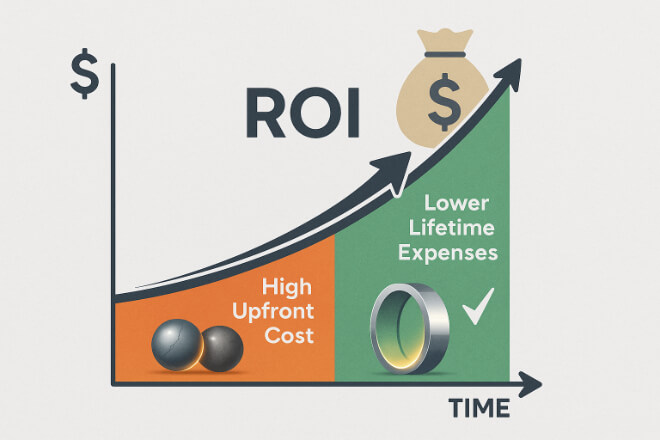

Cost and ROI Considerations

Seal rings with proper grinding and polishing cost more upfront. However, decision-makers benefit from:

Longer seal life (5–10x compared with poor finishing)

Fewer breakdowns and less downtime

Lower overall maintenance cost

Stronger return on investment

Case Studies

1). Offshore Drilling Pump

After switching to polished tungsten carbide seal rings, service life increased by 70%, reducing replacement frequency.

2). Chemical Plant Mixer

Using precision-ground rings reduced leakage, improving safety and cutting costs.

3). Power Plant Turbine

Polished rings lowered friction, reducing energy loss and extending equipment uptime.

How to Source High-Quality Seal Rings

When sourcing, companies should:

Ask suppliers about grinding and polishing processes

Confirm inspection reports and tolerance data

Choose ISO-certified manufacturers

Ensure availability of custom finishing options

Conclusion

Grinding and polishing are not optional—they are essential. Without them, tungsten carbide seal rings cannot deliver their full potential.

For decision-makers, investing in seal rings with precise grinding and polishing means stronger performance, safer systems, and better financial results.

If you want to know more details about any company, please feel free to contact us.