Mechanical seals are essential in pumps, compressors, turbines, and marine systems. Their main role is to stop leaks, protect equipment, and keep systems running safely.

However, the reliability of mechanical seals depends heavily on the quality of their sealing faces.

Among the many materials available, tungsten carbide seal rings stand out as one of the best choices for industries that need durability and efficiency.

This article explains how tungsten carbide seal rings improve mechanical seal reliability, reduce failures.

And add long-term value for industries such as oil and gas, power generation, chemical processing, and marine equipment.

What Are Tungsten Carbide Seal Rings?

Tungsten carbide is a compound of tungsten and carbon, bonded with cobalt or nickel to improve toughness. When used in seal rings, this material provides:

High hardness → Resists wear from friction and particles.

Excellent compressive strength → Handles extreme pressure without deformation.

Thermal stability → Performs reliably at high temperatures.

Corrosion resistance → Withstands chemicals, seawater, and oil.

Dimensional accuracy → Maintains tight seals under stress.

These properties make tungsten carbide seal rings ideal for mechanical seals in high-demand environments.

Why Mechanical Seal Reliability Matters

When mechanical seals fail, the consequences are serious:

Downtime → Stopping operations leads to lost production and revenue.

High repair costs → Replacing seals and repairing equipment is expensive.

Safety risks → Leaks of oil, chemicals, or gas can be dangerous.

Environmental damage → Leakage can cause regulatory penalties and reputational harm.

Improving seal reliability is not only a technical requirement but also a business priority.

How Tungsten Carbide Seal Rings Improve Reliability

1). Wear Resistance

Seal rings are constantly in contact with rotating shafts and fluid media.

Tungsten carbide’s hardness prevents rapid wear, keeping seals effective for longer periods.

2). Shock Resistance

In pumps and turbines, sudden pressure changes or vibration can break brittle materials like ceramics.

Tungsten carbide’s toughness allows it to survive mechanical shock and maintain sealing.

3). Corrosion Protection

In marine or chemical plants, fluids often attack metallic components.

Nickel-bonded tungsten carbide offers excellent corrosion resistance, preventing early seal failure.

4). Thermal Performance

High temperatures in power plants or oilfield pumps can weaken weaker materials.

Tungsten carbide maintains structural stability even under thermal stress, protecting seal integrity.

5). Precision Sealing

Tungsten carbide seal rings maintain dimensional stability, which ensures tight sealing. This reduces leakage and increases mechanical seal reliability.

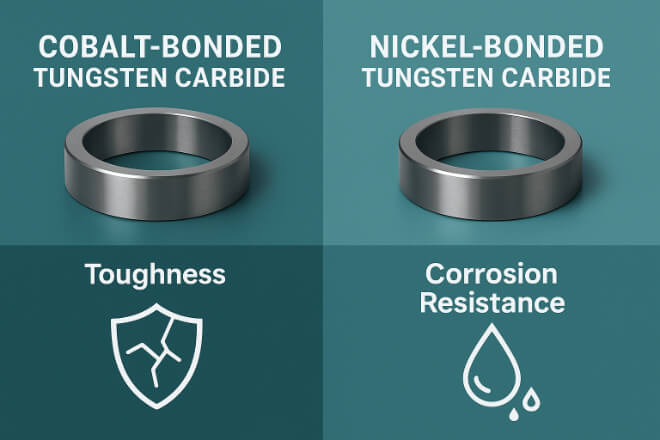

Cobalt-Bonded vs Nickel-Bonded Tungsten Carbide

For mechanical seals, two grades are common:

1). Cobalt-Bonded Tungsten Carbide

Stronger toughness

Best for shock and vibration

Slightly less corrosion resistant

2). Nickel-Bonded Tungsten Carbide

Superior corrosion resistance

Ideal for chemical and seawater applications

Slightly less tough than cobalt-bonded

Choosing the right grade depends on whether the main challenge is shock load or corrosion resistance.

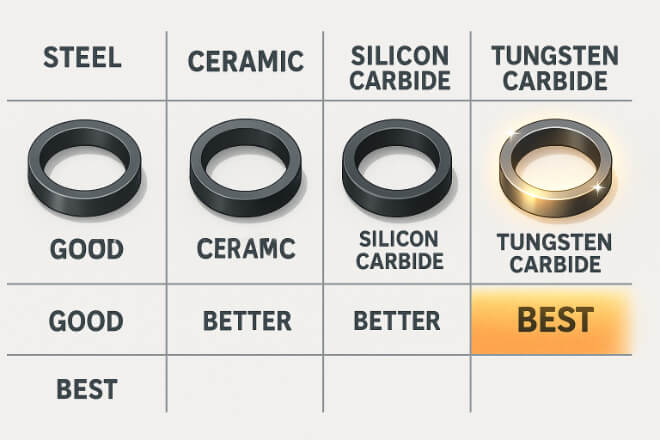

Comparison with Other Seal Ring Materials

Steel seals → Cheap but wear quickly and corrode.

Ceramic seals → Resist chemicals but break under impact.

Silicon carbide → Corrosion resistant but brittle in shock.

Tungsten carbide → Balanced solution: hard, tough, corrosion-resistant, and durable.

This balance is why tungsten carbide seal rings are trusted for mechanical seal reliability.

Industry Applications

Tungsten carbide seal rings are widely used in:

Oil and Gas – Compressors and pumps exposed to high loads.

Power Generation – Turbines and cooling pumps under continuous operation.

Chemical Plants – Equipment handling corrosive fluids.

Marine Systems – Pumps and engines exposed to seawater.

In each case, the rings help mechanical seals maintain long-term performance.

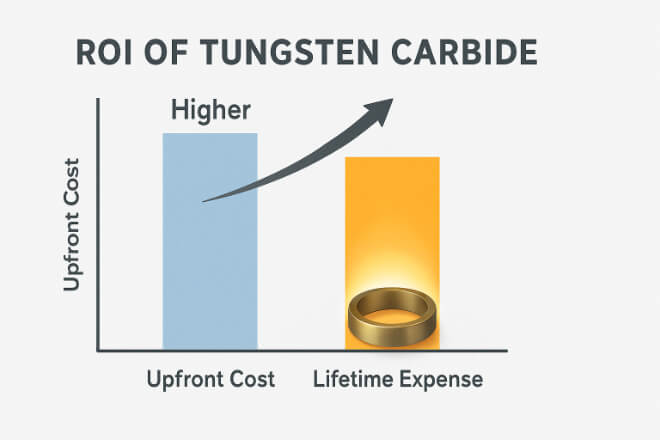

Cost vs Long-Term Value

While tungsten carbide seal rings are more expensive upfront, they provide:

Fewer replacements → Lower spare part costs.

Less downtime → Reduced production losses.

Longer equipment life → Lower repair expenses.

Higher ROI → Better total cost of ownership.

For decision-makers, investing in tungsten carbide means cost savings and reliability over time.

Maintenance Best Practices

To ensure maximum performance of tungsten carbide seal rings in mechanical seals:

Install correctly to avoid misalignment.

Inspect regularly for wear, cracks, or corrosion.

Lubricate properly to reduce friction and heat.

Match grade to environment (cobalt for shock, nickel for corrosion).

These practices extend service life and improve seal reliability.

Sustainability Advantage

Tungsten carbide seal rings can be recycled. Worn rings are collected, processed, and reused, reducing waste and supporting circular economy practices. This adds to their value in sustainability-focused industries.

Conclusion

Mechanical seal reliability is essential for safe and efficient operations. Tungsten carbide seal rings improve reliability by resisting wear, shock, corrosion, and heat better than most alternatives.

For decision-makers in oil and gas, power generation, marine, and chemical industries, tungsten carbide seal rings are not just a material choice—they are a strategic investment in safety, efficiency, and sustainability.

If you want to know more details about any company, please feel free to contact us.