Submersible pumps are widely used in industries such as oil and gas, mining, power generation, marine, and wastewater treatment.

These pumps operate underwater or in fluid-filled environments, often under high pressure, heat, and corrosive conditions.

One of the most important components in these pumps is the seal ring, which prevents leakage and protects the system.

For these demanding applications, tungsten carbide seal rings are the most reliable choice.

This article explains why they are essential for submersible pumps, their advantages, and what decision-makers need to know before selecting them.

The Role of Seal Rings in Submersible Pumps

Seal rings have the critical job of:

Preventing water, oil, or chemicals from leaking.

Protecting motor and bearings from fluid damage.

Reducing wear caused by friction.

Supporting long-term operation in harsh environments.

In submersible pumps, where seals are constantly exposed to fluids and pressure, weak materials fail quickly. This makes tungsten carbide a superior option.

Properties of Tungsten Carbide Seal Rings

Tungsten carbide is a compound of tungsten and carbon, usually bonded with cobalt or nickel. Its unique properties include:

Extreme hardness → Provides wear resistance against friction and particles.

High compressive strength → Handles heavy pressure without cracking.

Thermal stability → Maintains performance in high-temperature conditions.

Corrosion resistance → Withstands seawater, oil, and chemicals.

Dimensional stability → Ensures accurate sealing for long-term use.

These qualities make tungsten carbide seal rings ideal for underwater or high-pressure pump systems.

Why Tungsten Carbide Is Essential for Submersible Pumps

1). Wear Resistance

Submersible pumps often deal with fluids containing sand, silt, or abrasive particles. Tungsten carbide’s hardness helps the seal resist wear and last longer.

2). Corrosion Protection

In marine and wastewater systems, seals face constant exposure to corrosive fluids.

Nickel-bonded tungsten carbide provides strong resistance against these chemicals.

3). Pressure and Shock Resistance

Submersible pumps operate under high pressure.

Tungsten carbide can handle sudden pressure changes and mechanical shock better than ceramics or steel.

4). Longer Service Life

By resisting wear, corrosion, and shock, tungsten carbide seal rings last much longer than alternatives. This reduces downtime and replacement frequency.

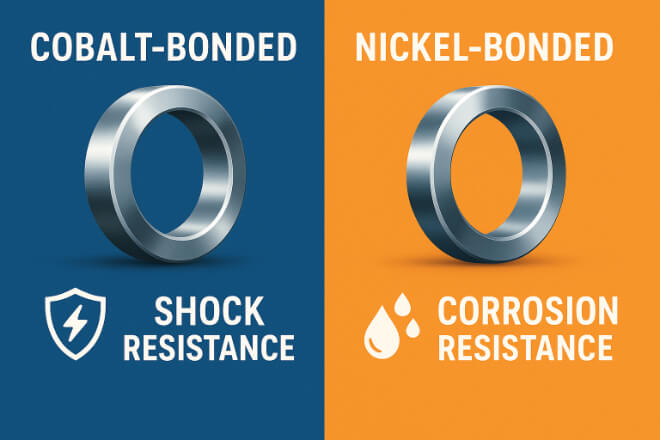

Cobalt-Bonded vs Nickel-Bonded Grades

Cobalt-bonded tungsten carbide → Better toughness, handles shock and vibration, best for mining and oilfield submersible pumps.

Nickel-bonded tungsten carbide → Better corrosion resistance, ideal for marine and wastewater submersible pumps.

Selecting the right binder ensures seal rings perform effectively in the pump’s operating environment.

Comparison with Other Seal Materials

Steel seals → Corrode quickly, poor for underwater use.

Ceramic seals → Corrosion resistant but brittle under shock.

Silicon carbide → Good chemical resistance but less tough under vibration.

Tungsten carbide → Best all-around balance of toughness, corrosion resistance, and durability.

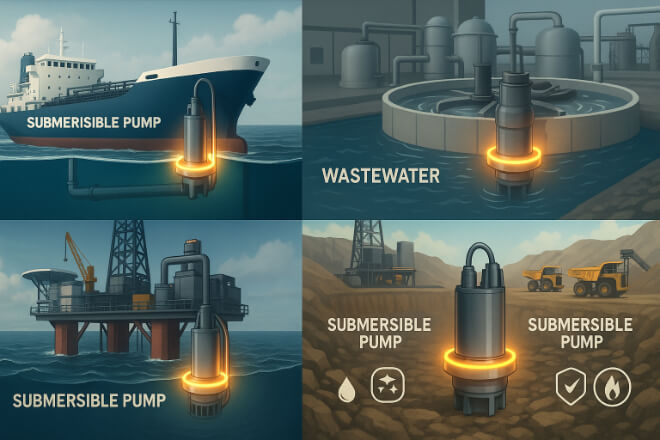

Applications of Tungsten Carbide Seal Rings in Submersible Pumps

Marine industry – Ballast pumps and cooling pumps exposed to seawater.

Wastewater treatment – Pumps handling corrosive and abrasive fluids.

Oilfield operations – Submersible pumps in drilling and extraction with sand and oil mixtures.

Mining – Submersible pumps exposed to slurry and abrasive particles.

Power generation – Cooling water pumps operating at high temperatures.

Across these applications, tungsten carbide ensures safe and reliable sealing.

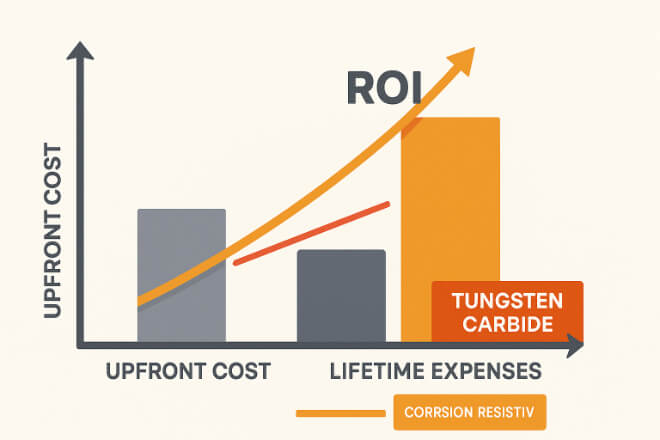

Cost vs Long-Term Value

While tungsten carbide seal rings cost more initially, they save money in the long run:

Fewer replacements → Lower spare part costs.

Reduced downtime → Higher productivity.

Less equipment damage → Protects motors and bearings.

Better ROI → Strong financial case for decision-makers.

Best Practices for Using Tungsten Carbide Seal Rings

To get the most from seal rings in submersible pumps:

Select the right grade → Nickel for corrosion, cobalt for shock.

Ensure correct installation → Avoid scratches that weaken seals.

Inspect regularly → Catch early signs of wear or corrosion.

Maintain lubrication → Prevents overheating and friction damage.

Sustainability and Recycling

Tungsten carbide seal rings are recyclable. Used rings can be collected and processed into new products.

This reduces waste and supports sustainable industrial practices, a growing priority for global companies.

Key Takeaways for Decision-Makers

Submersible pumps need reliable seals for safe operation.

Tungsten carbide seal rings resist wear, corrosion, and shock better than alternatives.

Nickel-bonded grades are best for corrosive environments, while cobalt-bonded grades are best for heavy-load conditions.

Higher upfront cost is offset by longer service life and reduced downtime.

Recycling adds an extra sustainability benefit.

Conclusion

For submersible pumps in marine, oilfield, wastewater, mining, and power industries, tungsten carbide seal rings are not optional—they are essential.

Their ability to handle pressure, corrosion, and shock ensures reliable performance and long-term savings.

For decision-makers, investing in tungsten carbide seal rings means greater efficiency, safety, and sustainability.

If you want to know more details about any company, please feel free to contact us.