In many industries, sealing systems are not standard—they are designed to meet unique engineering needs.

Equipment in oil and gas, chemical plants, marine operations, and power generation often faces conditions that off-the-shelf seal rings cannot handle.

This is why many companies turn to custom-made tungsten carbide seal rings.

This article explains why customization matters, what benefits tungsten carbide provides, and how decision-makers can ensure they select the right seal rings for their equipment.

Why Custom Seal Rings Are Needed

Standard seals may work in some applications, but many industries require special designs to handle:

Extreme pressure or temperature conditions.

Fluids with abrasive particles.

Aggressive chemicals or seawater.

Complex pump, turbine, or compressor designs.

A custom-made tungsten carbide seal ring ensures a perfect fit for these unique challenges, improving system reliability and reducing downtime.

Key Properties of Tungsten Carbide Seal Rings

Tungsten carbide is one of the hardest industrial materials. Its main properties make it ideal for custom solutions:

Extreme hardness → Resists wear from friction and abrasives.

High compressive strength → Handles very high loads and pressures.

Thermal stability → Maintains sealing ability in hot systems.

Corrosion resistance → Withstands chemicals, seawater, and oil.

Dimensional accuracy → Precision manufacturing ensures perfect fit in custom designs.

These features make tungsten carbide a flexible material for custom sealing requirements.

When Customization Brings the Most Value

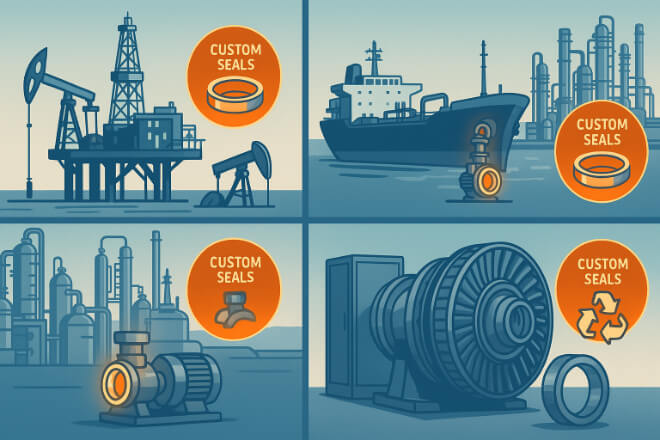

1). Oil and Gas

Downhole pumps and compressors face sand, pressure cycles, and corrosive fluids.

Custom tungsten carbide seal rings ensure tight sealing in these unique conditions.

2). Marine and Offshore

Seawater pumps and propulsion systems require seals with special corrosion-resistant grades.

Custom nickel-bonded tungsten carbide rings extend service life.

3). Chemical Processing

Different plants handle different chemicals. Customization allows for seal rings that resist specific acids, alkalis, or solvents.

4). Power Generation

Turbines and cooling systems require seal rings made for extreme temperature cycles, where standard designs may fail.

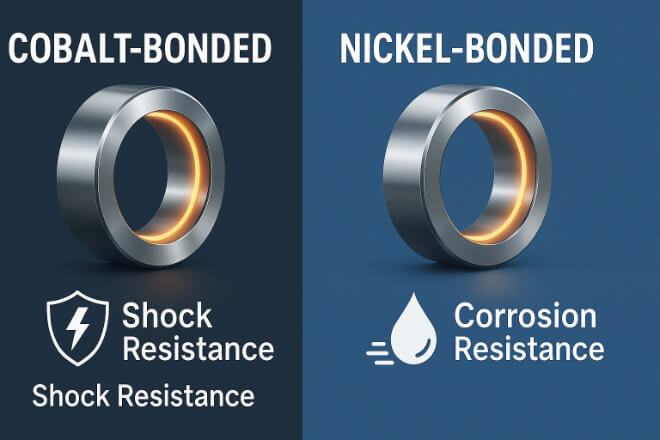

Cobalt-Bonded vs Nickel-Bonded Options

Custom seals often require a choice between binders:

1). Cobalt-bonded tungsten carbide

More toughness, good for vibration and shock.

Best in oil and gas or mining equipment.

2). Nickel-bonded tungsten carbide

Superior corrosion resistance.

Ideal for marine and chemical industries.

Customization allows decision-makers to select the right binder for specific needs.

Advantages of Custom-Made Tungsten Carbide Seal Rings

Perfect fit → Ensures compatibility with unique equipment.

Higher reliability → Reduces leakage risk and downtime.

Longer service life → Handles stress better than standard seals.

Improved efficiency → Custom design reduces energy loss from leaks.

Cost savings → Less downtime and fewer replacements.

For decision-makers, these advantages mean better return on investment.

Comparison with Standard Seal Rings

Standard seals → Lower upfront cost, but may fail in complex or harsh conditions.

Custom seals → Higher upfront investment, but better performance and longer life.

In demanding industries, custom tungsten carbide seal rings deliver lower life cycle cost.

How to Choose the Right Custom Seal Ring

Decision-makers should consider:

Operating conditions → Pressure, temperature, and fluid type.

Binder material → Nickel for corrosion, cobalt for toughness.

Design specifications → Dimensions, tolerances, and pump type.

Supplier quality → Work with certified suppliers who can manufacture to ISO standards.

These steps ensure that the seal rings meet both technical and financial goals.

Sustainability and Recycling

Custom-made tungsten carbide seal rings are also recyclable. Many suppliers collect worn rings and process them into new products. This supports sustainability and reduces raw material demand.

Key Takeaways for Decision-Makers

Standard seals are not always enough for unique engineering needs.

Custom tungsten carbide seal rings provide strength, precision, and durability.

Correct binder choice ensures maximum performance.

Higher upfront cost leads to lower long-term expenses.

Recycling adds to the sustainability value.

Conclusion

In today’s industries, where equipment faces unique challenges, custom-made tungsten carbide seal rings are essential. They provide the reliability, efficiency, and durability that standard seals cannot.

For decision-makers, choosing custom tungsten carbide seal rings means not just solving technical problems but also achieving strategic advantages in cost savings and sustainability.

If you want to know more details about any company, please feel free to contact us.