Slurry and abrasive fluids are some of the most challenging materials for industrial pumps, mixers, and turbines.

These fluids contain solid particles such as sand, silt, or minerals that can quickly damage equipment.

A reliable sealing system is essential to prevent leaks, reduce maintenance, and keep operations running smoothly.

Among the materials available, tungsten carbide seal rings are one of the best choices for slurry and abrasive fluid handling.

This article explains why, compares them to alternatives, and offers tips for decision-makers.

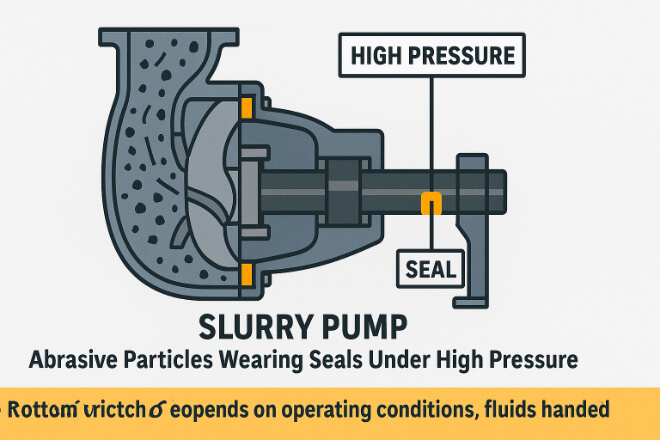

Challenges of Slurry and Abrasive Fluid Handling

Abrasive fluids create unique problems for seals and equipment:

Severe wear → Solid particles grind against seals, causing rapid damage.

High pressure → Slurry pumps often operate under extreme loads.

Variable flow → Uneven conditions can stress seals.

Corrosion → Many slurries include chemicals or seawater.

Downtime cost → Seal failure can stop production and cause expensive repairs.

These challenges require a material that can withstand heavy wear and stress.

Properties of Tungsten Carbide Seal Rings

Tungsten carbide is a composite of tungsten and carbon, bonded with cobalt or nickel. Its properties make it ideal for abrasive environments:

Extreme hardness → Resists scratching and erosion from particles.

High compressive strength → Handles pressure without cracking.

Wear resistance → Extends service life compared to steel or ceramic.

Corrosion resistance → Protects against chemical-rich slurries.

Thermal stability → Performs reliably under heat generated by friction.

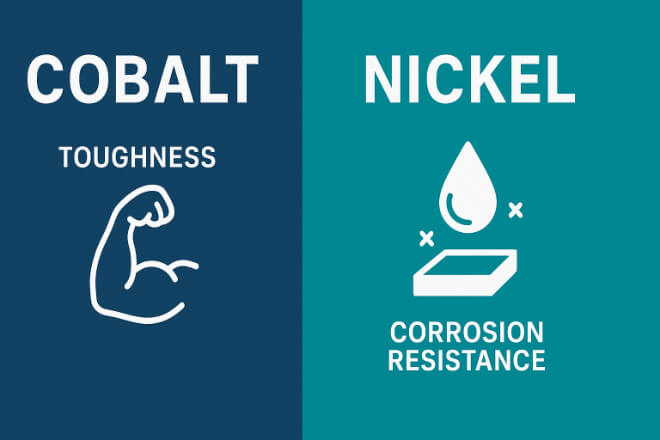

Cobalt-Bonded vs Nickel-Bonded Tungsten Carbide

Two main grades are used for slurry and abrasive fluids:

1). Cobalt-bonded tungsten carbide

Better toughness and shock resistance.

Best for mining, dredging, and oilfield slurry pumps.

2). Nickel-bonded tungsten carbide

Stronger corrosion resistance.

Better for slurries with chemicals or seawater.

Selecting the right binder ensures maximum seal life in your application.

Advantages Over Other Seal Materials

| Feature | Tungsten Carbide | Ceramic | Steel |

|---|---|---|---|

| Wear resistance | Excellent for abrasives | Moderate in slurry | Poor in abrasive fluids |

| Toughness | High; resists shock/vibration | Low; brittle under impact | Moderate |

| Corrosion resistance | Good; nickel-bonded excels | Excellent in chemicals | Poor in slurry/chemicals |

| Service life | Long-lasting under stress | Moderate | Short in harsh media |

| Cost | Higher upfront; better ROI | Lower initial cost | Lowest initial cost |

Applications in Slurry and Abrasive Fluid Systems

Tungsten carbide seal rings are widely used in:

Mining and dredging pumps – Handle mineral slurries with high abrasiveness.

Oilfield drilling systems – Manage abrasive drilling fluids under pressure.

Wastewater treatment – Resist wear in grit-filled fluids.

Marine and dredging operations – Provide durability in sandy seawater.

Chemical plants – Handle corrosive and abrasive mixtures safely.

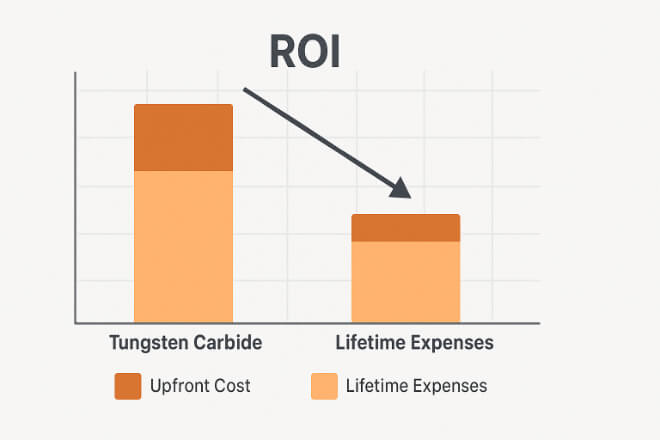

Cost vs Long-Term Value

While tungsten carbide seal rings cost more upfront, they:

Reduce downtime → Less frequent failures and replacements.

Lower maintenance costs → Fewer labor hours and spare parts.

Protect equipment → Prevent expensive damage to pumps and shafts.

Improve ROI → Longer service life offsets initial price.

Decision-makers in slurry handling benefit from lower life cycle cost over time.

Best Practices for Using Tungsten Carbide Seal Rings

To maximize performance in abrasive environments:

Choose the correct binder → Nickel for corrosive slurries, cobalt for impact loads.

Install carefully → Avoid scratches or misalignment that shorten life.

Use proper lubrication → Reduces heat and friction wear.

Inspect regularly → Spot early wear to prevent failure.

Work with experienced suppliers → Ensure proper material and design for your system.

Environmental Benefits

Tungsten carbide is recyclable. Worn rings can be collected and reprocessed into new products, reducing waste and supporting environmental sustainability—a growing priority for industries worldwide.

Key Takeaways for Decision-Makers

Tungsten carbide seal rings outperform steel and ceramic in abrasive, high-pressure environments.

The right binder (nickel or cobalt) ensures reliability under specific conditions.

Though costlier upfront, tungsten carbide reduces downtime and overall expenses.

Recyclability adds sustainability benefits.

Conclusion

Handling slurry and abrasive fluids requires seals that can survive extreme wear, pressure, and corrosion.

Tungsten carbide seal rings deliver the toughness and durability needed to keep pumps, compressors, and turbines operating safely and efficiently.

For decision-makers, choosing tungsten carbide is a strategic investment in uptime, performance, and sustainability.

If you want to know more details about any company, please feel free to contact us.