Cryogenic and extreme cold environments—such as liquefied natural gas (LNG) plants, aerospace testing facilities, scientific labs, and deep-sea systems—require sealing solutions that can perform reliably at very low temperatures.

In these environments, materials become brittle, fluids behave differently, and any failure can cause costly downtime or safety hazards.

Tungsten carbide seal rings are a trusted choice for pumps, compressors, and turbines operating in these harsh conditions.

This article explains their properties, advantages, applications, and best practices for decision-makers.

Challenges of Cryogenic and Extreme Cold Conditions

Operating at temperatures as low as -196 °C (-320 °F) creates challenges:

Material brittleness → Metals and plastics can crack or deform.

Thermal contraction → Components shrink, causing misalignment.

Lubrication issues → Fluids thicken or freeze, increasing friction.

Seal failure risks → Even small leaks can cause dangerous situations.

Downtime costs → Repairs at cryogenic facilities are expensive.

Properties of Tungsten Carbide Seal Rings

Tungsten carbide is a composite of tungsten and carbon, bonded with cobalt or nickel. Its properties make it ideal for extreme cold:

High hardness → Maintains strength and wear resistance.

Low thermal expansion → Reduces dimensional changes during cooling.

Toughness → Resists cracking from thermal shock or vibration.

Corrosion resistance → Performs well with cryogenic fluids like LNG or liquid oxygen.

Long service life → Reduces maintenance and replacements.

Cobalt-Bonded vs Nickel-Bonded Tungsten Carbide

1). Cobalt-bonded tungsten carbide

Greater impact resistance.

Suitable for pumps and compressors exposed to vibration.

2). Nickel-bonded tungsten carbide

Superior corrosion resistance.

Best for cryogenic systems handling oxygen, hydrogen, or chemical-rich fluids.

Advantages Over Other Seal Materials

| Feature | Tungsten Carbide | Ceramic | Steel |

|---|---|---|---|

| Low-Temperature Toughness | Excellent | Low, brittle | Moderate |

| Wear Resistance | Excellent | Moderate | Poor |

| Corrosion Resistance | High (nickel grades) | Very Good | Low |

| Thermal Contraction | Low | Moderate | High |

| Service Life | Long-lasting | Moderate | Short |

Applications in Cryogenic and Cold Environments

Tungsten carbide seal rings are widely used in:

LNG pumps and compressors → Ensure leak-free transfer of liquefied gases.

Aerospace cryogenic testing systems → Handle extreme cold during rocket or satellite testing.

Scientific laboratories → Maintain seal integrity in liquid nitrogen systems.

Marine deep-sea equipment → Resist high pressure and freezing seawater.

Hydrogen fuel systems → Provide safe sealing for clean energy applications.

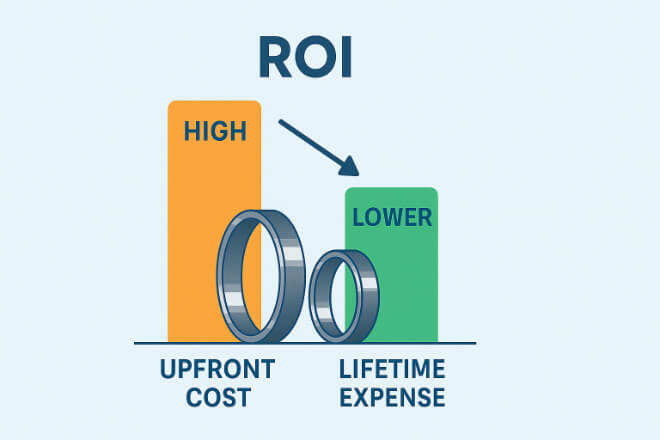

Cost vs Long-Term Value

While tungsten carbide seal rings have a higher upfront price, they:

Reduce downtime by lasting longer.

Lower maintenance costs with fewer replacements.

Protect critical equipment from leaks and damage.

Deliver better ROI in high-risk, cold environments.

Environmental and Safety Benefits

Leak prevention → Reduces risk of environmental contamination.

Recyclable material → Supports sustainability goals.

Improved efficiency → Leak-free systems consume less energy.

Best Practices for Using Tungsten Carbide Seal Rings

Match binder to environment → Nickel for corrosive cryogenic fluids, cobalt for high vibration.

Use proper installation techniques → Avoid scratches or misalignment.

Inspect regularly → Spot wear or contraction damage early.

Work with experienced suppliers → Ensure correct specifications for cryogenic conditions.

Plan maintenance schedules → Avoid unplanned shutdowns in critical systems.

Key Takeaways for Decision-Makers

Tungsten carbide seal rings are the best choice for cryogenic and extreme cold applications.

Their low thermal expansion, corrosion resistance, and toughness prevent leaks and damage.

Correct binder selection (nickel or cobalt) maximizes reliability.

Investing in tungsten carbide reduces downtime, cost, and environmental risks.

Conclusion

In cryogenic and extreme cold systems, seal reliability is critical. Tungsten carbide seal rings provide unmatched performance, ensuring pumps, compressors, and turbines remain leak-free even under severe conditions.

For decision-makers, selecting tungsten carbide is a strategic investment in safety, efficiency, and sustainability.

If you want to know more details about any company, please feel free to contact us.