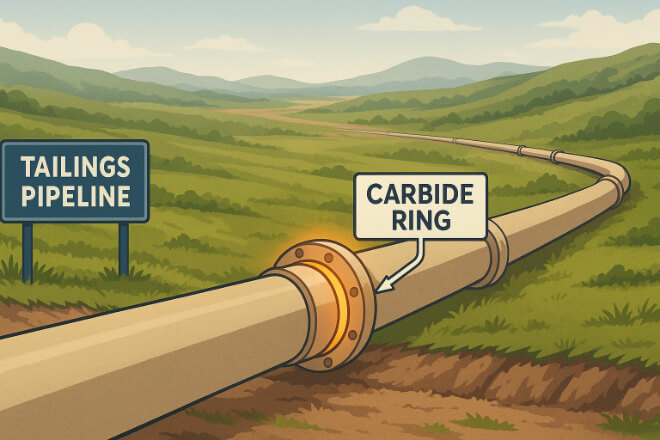

In mining and mineral processing, slurry transfer systems and tailings pipelines move abrasive mixtures of water, rock, and sand. These fluids are tough on equipment.

Pumps, valves, and pipelines must survive constant wear and pressure. One of the most critical components in these systems is the carbide seal ring.

Carbide seal rings protect pumps and valves by preventing leaks and reducing wear. Their hardness, strength, and corrosion resistance make them ideal for these demanding environments.

For decision-makers, choosing carbide seal rings means longer service life, fewer failures, and better return on investment.

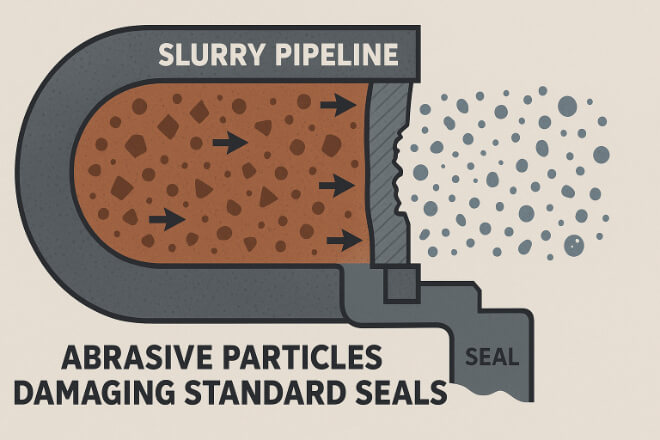

Challenges in Slurry and Tailings Transport

Slurry and tailings present unique problems:

Abrasive particles cause rapid wear on seals

High pressures and long pipeline distances stress components

Variable pH levels in tailings fluids cause corrosion

Continuous operation makes downtime costly

Standard materials like stainless steel or carbon graphite fail quickly under these conditions.

Carbide seal rings are engineered to handle the harshness of mining operations.

Why Carbide Seal Rings Are the Best Choice

1). Superior Hardness

Carbide is almost as hard as diamond, resisting scratches and wear from sharp particles.

2). High Strength and Toughness

Carbide seal rings withstand high pressure and shock loads common in slurry pumps and tailings pipelines.

Nickel-bonded carbide resists acids, alkalis, and other chemicals found in tailings.

4). Long Service Life

Fewer replacements and less downtime save time and money.

5). Stable at High Temperatures

Carbide rings keep their shape and sealing performance even under hot conditions.

Applications in Slurry Transfer Systems

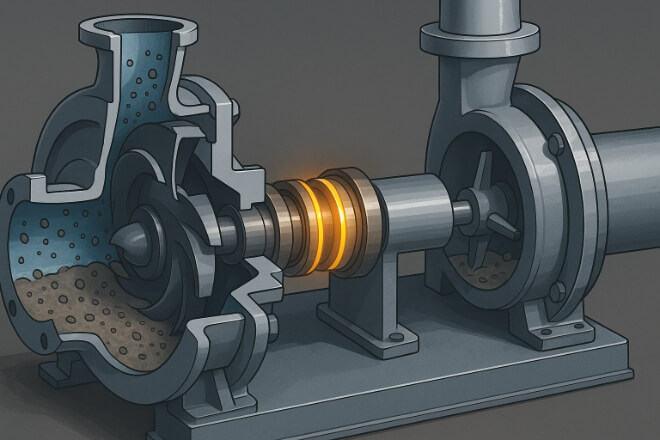

1). Slurry Pumps

Carbide seal rings prevent leaks in slurry pumps handling abrasive rock-water mixtures.

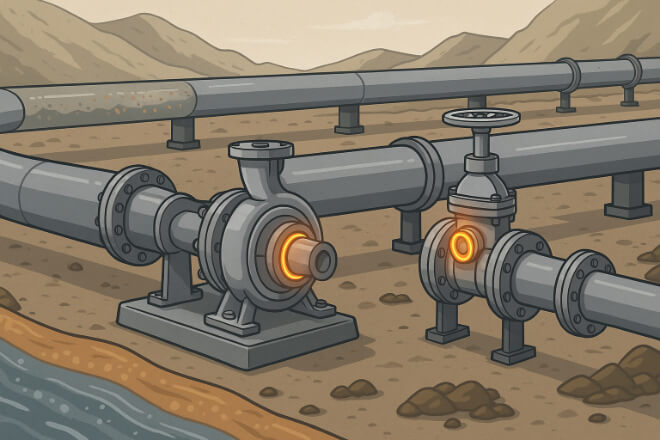

2). Valves and Fittings

Valves exposed to slurry flows rely on carbide rings for reliable sealing.

3). Mixers and Agitators

Carbide rings reduce friction and extend life in mixing equipment that handles heavy slurries.

Applications in Tailings Pipelines

1). Tailings Disposal Pumps

Pumps that move tailings to storage areas face extreme abrasion. Carbide seal rings ensure durability.

2). Pipeline Valves

Carbide seals maintain tight closures even after long exposure to abrasive tailings.

3). Thickener Discharge Systems

Carbide rings protect equipment where thickened tailings are handled at high pressure.

Benefits for Mining Operations

| Benefit | Description |

|---|---|

| Longer Service Life | Resists wear and corrosion, reducing replacement frequency. |

| Reduced Downtime | Fewer failures mean pumps and pipelines stay operational. |

| Improved Safety | Reliable sealing prevents leaks of hazardous tailings fluids. |

| Cost Savings | Less maintenance and fewer replacements reduce total cost of ownership. |

| Higher Efficiency | Smooth, polished carbide surfaces reduce friction and energy loss. |

Case Studies

1). Mining Pump Upgrade

A copper mine replaced stainless steel seals with carbide rings. Result: seal life tripled, saving thousands in maintenance.

2). Tailings Pipeline Reliability

A gold processing plant switched to nickel-bonded carbide seals, reducing leaks by 50% and improving environmental compliance.

How to Select the Right Carbide Seal Ring

1). Binder Type

Nickel-bonded for corrosion resistance in acidic tailings

Cobalt-bonded for toughness under heavy shock

2). Surface Finish

- Polished surfaces for smoother flow and reduced friction

3). Operating Conditions

- Consider pressure, temperature, and slurry composition

4). Supplier Quality

- Choose ISO-certified suppliers with mining experience

Maintenance and Replacement Strategy

Inspect seals regularly for cracks or uneven wear

Replace before total failure to avoid costly downtime

Keep spare carbide seals in stock for critical pumps

Recycle worn carbide rings to lower cost and waste

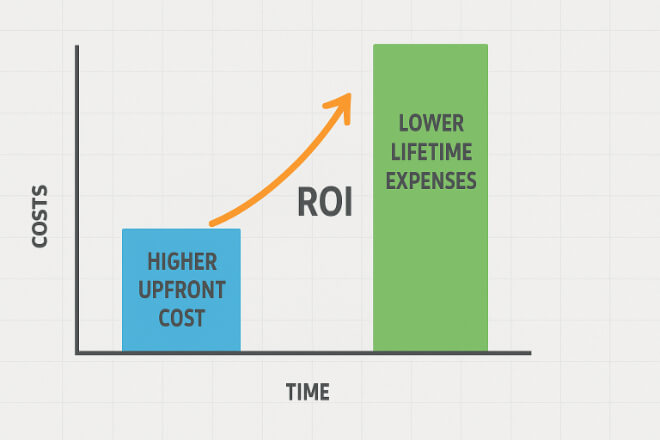

Cost and ROI Considerations

While carbide seal rings cost more upfront than steel or graphite, the long-term benefits are clear:

5–10x longer life reduces replacement needs

Less downtime improves production rates

Lower risk of leaks protects the environment

Better ROI through reduced total cost of ownership

Environmental and Safety Advantages

Tailings leaks can cause environmental damage and fines. Carbide seals improve pipeline reliability, protecting both the environment and worker safety.

Conclusion

Carbide seal rings are the smart choice for slurry transfer and tailings pipelines. Their hardness, corrosion resistance, and toughness make them ideal for harsh mining conditions.

For decision-makers, investing in carbide seal rings means safer operations, lower maintenance, and higher profits.

As mining demands grow, reliable sealing solutions like carbide rings will remain essential for efficiency and environmental responsibility.

If you want to know more details about any company, please feel free to contact us.