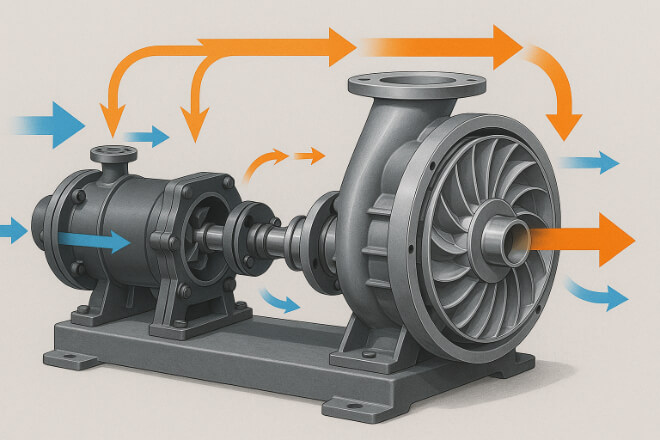

Turbo compressors and vacuum systems are critical in refineries, chemical plants, cleanrooms, and power stations.

They manage fast-moving gases, pressure extremes, and sensitive vacuum environments. Even a minor seal leak can stop production, waste energy, or risk contamination.

Carbide seal rings provide the reliability these systems demand. Known for their toughness, heat stability, and chemical resistance, they outperform many traditional sealing materials.

For operations managers, upgrading to carbide seals can mean fewer failures, smoother processes, and measurable cost savings.

Key Challenges in These Systems

Extreme rotor speeds generate high friction and surface wear.

Rapid pressure shifts stress compressor seals.

Corrosive gases or cleaning chemicals attack weaker materials.

Vacuum sensitivity requires absolute sealing to maintain product quality.

Conventional metals or plastics often cannot handle these combined stresses, making carbide a superior choice.

Advantages of Carbide Seal Rings

Wear Resistance: The hardness of carbide prevents surface scratches, even under high-speed contact.

Corrosion Protection: Nickel-bonded carbide resists aggressive gases used in petrochemicals or semiconductor manufacturing.

Mechanical Strength: Cobalt-bonded carbide absorbs vibration and shock loads in turbo compressors.

Thermal Stability: Carbide maintains sealing integrity even when compressors heat up or vacuum pumps cycle between temperatures.

Long-Term Reliability: Extended lifespan reduces unexpected outages and maintenance calls.

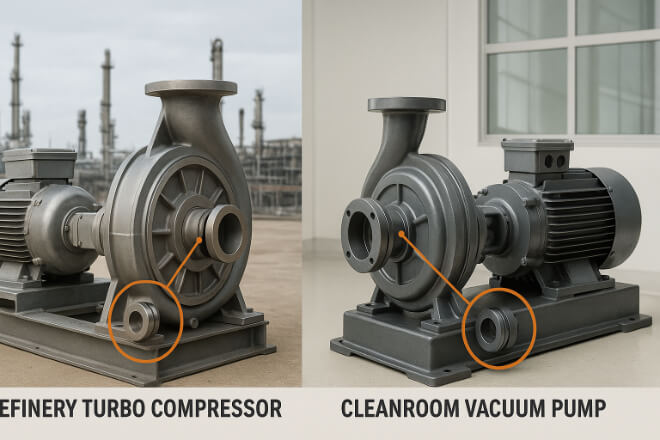

Where They Deliver Value

1). Turbo Compressors

Natural Gas Compression: Keeps gases sealed under heavy loads.

Refinery Operations: Prevents hazardous leaks during pressure surges.

Power Turbomachinery: Ensures consistent performance under constant high speeds.

2). Vacuum Systems

Electronics Cleanrooms: Maintains contaminant-free vacuums for chip production.

Pharma Manufacturing: Protects sterile environments in vacuum drying or distillation.

Food Packaging: Keeps vacuum integrity in continuous sealing equipment.

Benefits for Industrial Operations

| Benefit | Operational Impact |

|---|---|

| Durability | Survives abrasion and high-speed wear, extending seal life. |

| Lower Downtime | Fewer seal changes keep compressors and pumps online longer. |

| Safety Assurance | Reduces risk of gas leaks or vacuum collapse that can harm staff or products. |

| Energy Efficiency | Smooth surfaces minimize friction, improving equipment efficiency. |

| Cost Effectiveness | Longer service life offsets initial higher purchase price. |

Example Scenarios

Chemical Plant Compressor: After switching to carbide seals, unplanned outages dropped by 45%, reducing lost production.

Semiconductor Vacuum Pumps: Upgrading seals improved product yield by preventing micro-contaminants from leaks.

Selecting the Right Carbide Seal Ring

1). Binder Selection

Use nickel-bonded carbide for chemically aggressive gases.

Choose cobalt-bonded carbide for vibration-heavy turbo machines.

2). Surface Quality

Opt for polished carbide to reduce friction and heat buildup.

3). Operating Environment

Evaluate pressure, temperature, and gas composition.

4). Supplier Credentials

Partner with ISO-certified vendors familiar with compressors and vacuum systems.

Maintenance Practices

Schedule regular inspections during planned plant outages.

Replace seals proactively to avoid vacuum loss or compressor inefficiency.

Keep spare carbide rings on hand for critical systems.

Recycle used carbide components to reduce environmental impact.

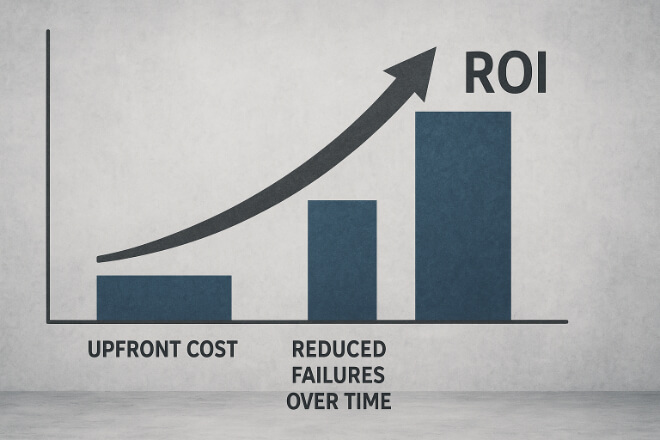

Cost and ROI Insights

Though carbide seals cost more upfront, they:

Last significantly longer than steel or ceramic alternatives.

Lower labor and emergency repair costs.

Improve equipment reliability, avoiding costly shutdowns.

Deliver stronger ROI through uptime and energy savings.

Environmental and Safety Considerations

Gas leaks or vacuum failures can release harmful emissions or spoil sensitive products. Carbide seal rings help operators stay compliant with environmental standards and protect workers from exposure.

Conclusion

Carbide seal rings are a smart investment for turbo compressors and vacuum systems.

Their combination of hardness, corrosion resistance, and thermal stability makes them essential for maintaining performance under extreme industrial conditions.

For decision-makers, using carbide seals means stable operations, lower costs, and safer workplaces—critical factors for competitiveness in power, petrochemical, and high-tech manufacturing industries.

If you want to know more details about any company, please feel free to contact us.