Mechanical seals are essential for pumps, compressors, and mixers used in power generation, chemicals, oil & gas, and water treatment.

Carbide seal faces are among the most reliable materials for these seals. Two key material properties—elastic modulus and compressive strength—play a major role in seal face stability.

Choosing carbide faces without understanding these properties can lead to cracks, leaks, and costly downtime.

This article explains modulus and compressive strength in simple terms, shows their impact on seal performance, and helps decision-makers choose the right carbide grade.

Why Stability Matters for Carbide Seal Faces

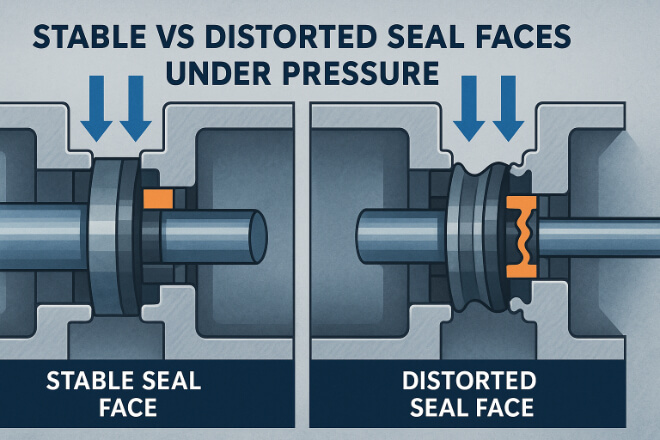

Leak prevention: Stable faces keep tight contact under pressure.

Reduced wear: Proper stiffness prevents distortion under load.

Energy efficiency: Flat, stable faces reduce friction and power loss.

Longer service life: Avoiding cracks and deformation reduces maintenance costs.

Understanding Elastic Modulus

Elastic modulus (also called Young’s modulus) measures how stiff a material is when force is applied.

High modulus: Material is very stiff and resists bending.

Low modulus: Material is more flexible and may bend under pressure.

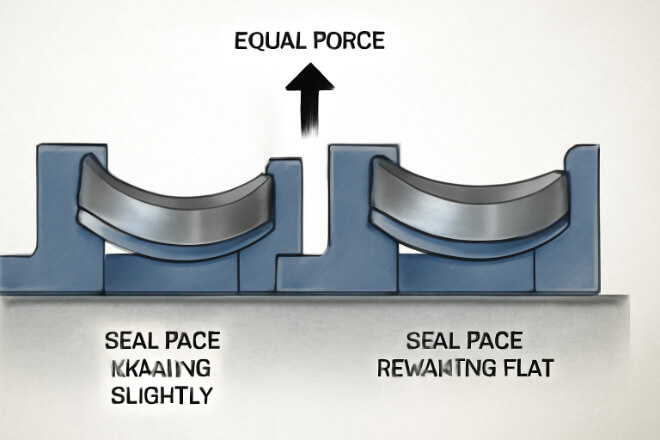

In carbide seal faces, a higher modulus means the surface stays flat when the pump or compressor is under pressure. This helps maintain a tight seal and prevents uneven wear.

1). Practical Example

In a high-pressure boiler feed pump, a carbide face with a low modulus may flex slightly, creating gaps for leaks.

A high-modulus carbide stays flat, protecting the equipment.

Understanding Compressive Strength

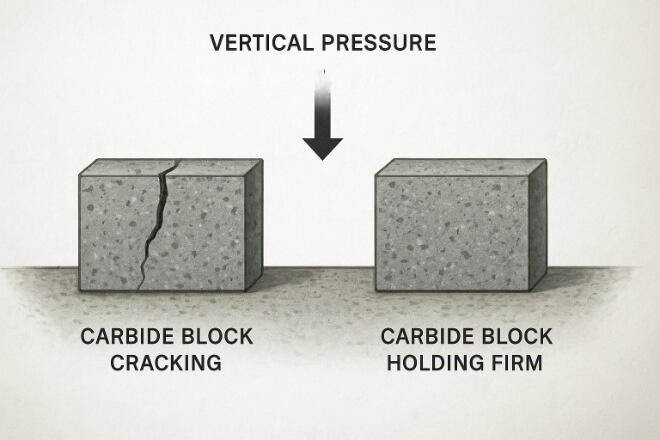

Compressive strength measures how much pressure a material can withstand before it fails.

High compressive strength: The material resists crushing under load.

Low compressive strength: The material may crack or deform under pressure.

Carbide is known for very high compressive strength—often greater than 600,000 psi—which is why it performs so well in pumps handling high-pressure or abrasive fluids.

1). Practical Example

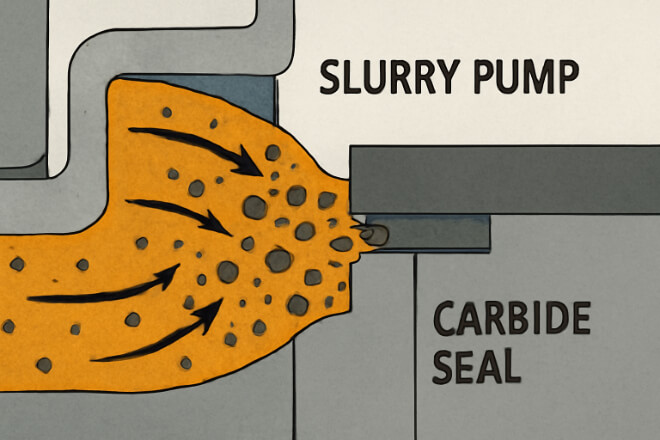

In slurry pumps moving abrasive mixtures, high compressive strength prevents the seal faces from cracking under particle impacts.

Comparison of Common Carbide Grades

| Carbide Grade | Elastic Modulus (GPa) | Compressive Strength (MPa) | Best Use |

|---|---|---|---|

| Nickel-Bonded Carbide | 540–570 | >5,500 | Corrosive chemical pumps |

| Cobalt-Bonded Carbide | 600–630 | >6,000 | High-shock, slurry service |

| Silicon Carbide (for comparison) | 400–450 | >3,500 | Aggressive chemicals, clean fluids |

How Modulus Affects Seal Performance

Face Flatness: A high modulus keeps seal faces flat under pressure, preventing leaks.

Wear Pattern: Lower modulus materials may tilt, creating uneven wear and early failure.

Thermal Stability: Stiffer faces maintain shape under heat buildup.

How Compressive Strength Affects Seal Performance

Crack Resistance: High compressive strength prevents fractures from particle impacts.

Pressure Handling: Handles extreme pressures in pumps or compressors without deforming.

Longer Lifespan: Reduces costly downtime by surviving harsh loads.

Selecting the Right Carbide for Your Application

For corrosive chemicals: Nickel-bonded carbide offers high corrosion resistance and strong compressive strength.

For abrasive slurries or vibration: Cobalt-bonded carbide provides extra toughness and stiffness.

For extreme pressure and temperature cycles: Choose carbide with both high modulus and high compressive strength.

For clean fluids with moderate pressure: Silicon carbide may work if corrosion is the main concern.

Industry Use Cases

Petrochemical Pumps: High-pressure pumps use cobalt-bonded carbide for stiffness and strength.

Marine Seawater Systems: Nickel-bonded carbide prevents corrosion from saltwater.

Power Generation Feed Pumps: High modulus and compressive strength reduce leaks during thermal cycling.

Mining Slurry Equipment: Tough cobalt-bonded carbides survive particle impacts and vibration.

Maintenance Tips

Inspect faces for signs of distortion or small cracks.

Use clean flushing fluids to cool and lubricate seals.

Replace damaged rings in pairs for balanced performance.

Work with suppliers who can provide detailed mechanical property data.

Cost and ROI Considerations

Upfront Cost: High-modulus carbides may cost more but last longer.

Savings: Fewer replacements reduce labor and downtime.

ROI: Improved equipment uptime and safety justify the investment.

Environmental and Safety Benefits

Stable seal faces prevent leaks of hazardous chemicals or hot fluids. Reliable performance also reduces the risk of equipment failure, protecting workers and the environment.

Conclusion

Modulus and compressive strength are critical for carbide seal face stability. High modulus keeps faces flat under load, while high compressive strength prevents cracking under pressure.

For decision-makers, understanding these properties ensures better reliability, longer equipment life, and reduced maintenance costs in demanding industrial applications.

If you want to know more details about any company, please feel free to contact us.