When it comes to mechanical parts that face constant wear, pressure, and friction, tungsten carbide bushings are among the most trusted materials.

They are used in pumps, compressors, turbines, and other high-load systems where failure is not an option.

Their outstanding durability comes mainly from two material properties — hardness and toughness. Both are vital, but they behave differently and often pull in opposite directions.

This article helps you understand what hardness and toughness mean, how they influence the performance of tungsten carbide bushings, and how the right balance leads to long-lasting reliability in harsh industrial conditions.

What Is Hardness?

Hardness measures how well a material resists deformation, scratching, or indentation. In simple words, it tells us how difficult it is to cut or wear the surface.

Tungsten carbide is known for its exceptional hardness, which ranges between 88–92 HRA, making it one of the hardest materials used in engineering — second only to diamond.

This hardness allows carbide bushings to:

Resist wear in abrasive environments

Keep tight clearances even under pressure

Maintain shape and surface quality over long operating hours

1). Typical Hardness Comparison

| Material | Hardness (HRA) | Relative Wear Resistance |

|---|---|---|

| Bronze | 45–60 | Low |

| Hardened Steel | 65–75 | Moderate |

| Tungsten Carbide | 88–92 | Very High |

The higher the hardness, the more resistant the bushing is to scratches, grooves, and deformation caused by sliding contact with shafts or abrasive particles.

What Is Toughness?

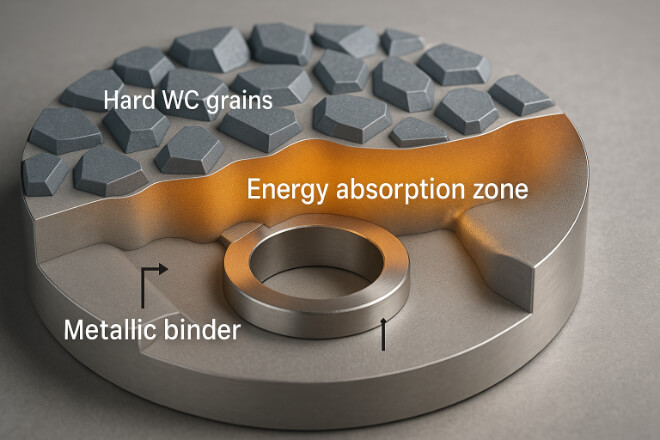

Toughness is the ability of a material to absorb energy and resist cracking or breaking under impact or stress.

While hardness prevents wear, toughness prevents brittle failure.

A material that is very hard but not tough can crack easily under vibration or shock loads.

Toughness depends on:

The type and amount of binder (Cobalt or Nickel)

The grain size of tungsten carbide particles

The sintering quality and porosity level

Tungsten carbide bushings achieve toughness through their composite structure — hard WC grains bonded by a softer, ductile metal binder that absorbs impact energy.

The Hardness–Toughness Balance

In material science, hardness and toughness are often in conflict. Increasing hardness (by reducing binder or grain size) usually lowers toughness.

The best tungsten carbide bushings are those that strike the right balance between the two — hard enough to resist wear, but tough enough to resist cracking.

1). Typical Balance by Binder Content

| Binder Percentage | Hardness (HRA) | Relative Toughness | Typical Application |

|---|---|---|---|

| 6% | 91–92 | Moderate | High-speed, light load |

| 9% | 89–90 | High | General-purpose pumps |

| 12% | 87–88 | Very High | Heavy-duty slurry or oilfield use |

Engineers select the grade based on working conditions — high hardness for precision, and high toughness for shock or impact situations.

The Role of Grain Size

Tungsten carbide bushings can be made from coarse-grain, medium-grain, or fine-grain powders.

Smaller grains increase hardness and improve surface finish. Larger grains add toughness and crack resistance.

| Grain Type | Typical Size | Main Benefit | Common Application |

|---|---|---|---|

| Fine-grain (0.5–1 µm) | Very small | High hardness, mirror polish | Seal rings, high-speed pumps |

| Medium-grain (1–3 µm) | Balanced | Good mix of wear and shock resistance | Compressors, turbines |

| Coarse-grain (3–6 µm) | Large | High impact toughness | Mining, slurry pumps |

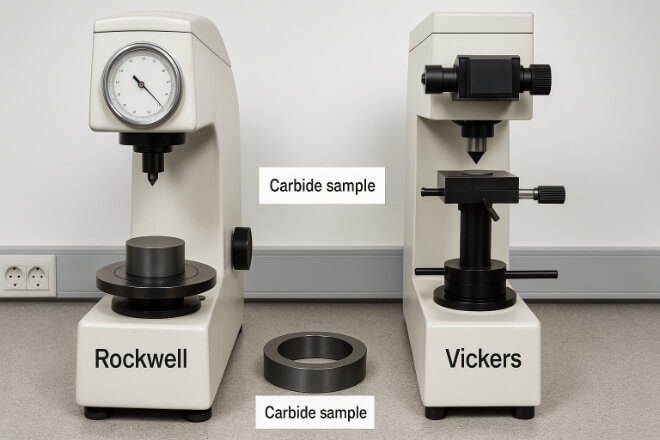

Hardness Testing Methods

Manufacturers verify carbide hardness using several standard tests:

Rockwell A (HRA): Most common for tungsten carbide; small conical diamond indenter under 60 kgf load.

Vickers (HV): Uses a square diamond pyramid and measures indentation size under controlled force.

Knoop (HK): Used for microhardness testing of thin coatings or small samples.

Each test ensures the material meets the required hardness specification for its intended service.

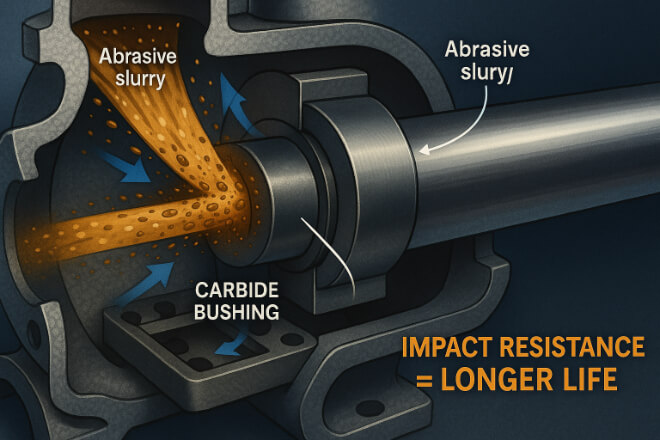

Why Toughness Matters in Real Applications

Even the hardest carbide can fail if it lacks toughness.

Real industrial environments involve vibration, pressure fluctuation, and misalignment — all of which can cause stress.

For example:

In slurry pumps, sudden particle impact can chip hard but brittle materials.

In compressors, vibration or dry running can lead to thermal shock.

Tougher carbide grades prevent catastrophic cracking, reducing downtime and replacement costs.

Comparing Tungsten Carbide to Other Materials

| Property | Tungsten Carbide | Ceramics | Hardened Steel |

|---|---|---|---|

| Hardness | Very High (88–92 HRA) | Very High (90+ HRA) | Moderate (70 HRA) |

| Toughness | High (metallic binder) | Low (brittle) | Moderate |

| Corrosion Resistance | Excellent (Ni-bonded) | Good | Limited |

Tungsten carbide stands out because it combines the hardness of ceramics with the toughness of metals, making it the best choice for severe wear conditions.

Real-World Selection Examples

| Application | Required Property | Recommended Grade | Binder Type |

|---|---|---|---|

| Clean water pump | High hardness, smooth finish | Fine-grain WC | Co 6% |

| Slurry pump | Impact and erosion resistance | Coarse-grain WC | Co 12% |

| Seawater pump | Corrosion resistance | Fine-grain WC | Ni 8% |

| Compressor | Thermal stability | Medium-grain WC | Co 9% |

Choosing the correct combination ensures the bushing performs optimally in its environment.

Conclusion

Understanding hardness and toughness helps engineers select the right tungsten carbide grade for their application.

Hardness provides wear resistance and dimensional accuracy.

Toughness prevents cracking and failure under shock.

The best-performing bushings balance these properties for long service life and reliability.

For industries where downtime is costly, this balance directly impacts operating efficiency and total cost of ownership.

If you want to know more details about any company, please feel free to contact us.