Tungsten carbide bushings are widely used in pumps, compressors, turbines, and rotating machinery.

They provide exceptional wear resistance, strength, and dimensional stability under harsh conditions.

However, prices for tungsten carbide bushings vary greatly from one supplier to another.

Understanding what drives these costs helps buyers make smarter procurement decisions — balancing performance, reliability, and long-term value rather than just price alone.

This article explains the main factors that affect the cost of tungsten carbide bushings, from raw materials to precision finishing, coatings, and logistics.

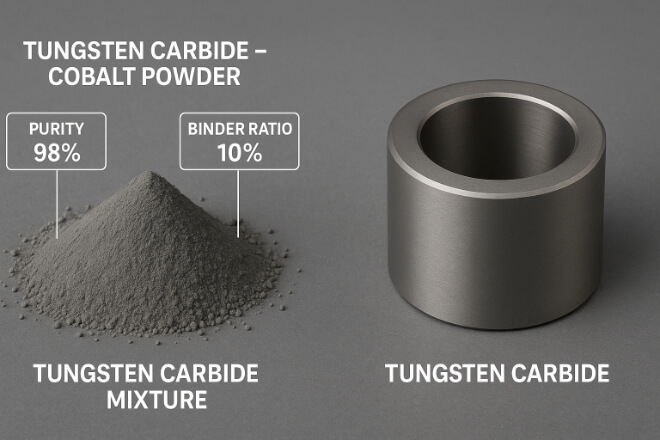

Raw Material Composition

The largest cost driver is the tungsten carbide powder itself. It’s a blend of tungsten carbide (WC) particles and a metal binder such as cobalt (Co) or nickel (Ni).

Key factors influencing material cost:

Tungsten Powder Purity: Higher purity WC provides better hardness but costs more.

Binder Type: Nickel-bonded carbide is more corrosion-resistant but pricier than cobalt-bonded grades.

Binder Percentage: Higher binder levels improve toughness but slightly reduce hardness — impacting both performance and cost.

| Material Type | Cost Level | Typical Use |

|---|---|---|

| Cobalt-Bonded (6–12%) | Medium | General industrial and mechanical seals |

| Nickel-Bonded (8–15%) | High | Chemical and corrosive media applications |

| WC-TiC or WC-CrC Composites | Very High | Extreme wear or high-temperature environments |

Raw material costs can represent 40–60% of the total price of a finished bushing.

Grain Size and Grade Selection

The microstructure of tungsten carbide affects both performance and manufacturing complexity.

Fine-grain or sub-micron grades provide higher hardness and better surface finish but are more difficult to press and sinter.

| Grain Type | Typical Particle Size | Relative Cost | Properties |

|---|---|---|---|

| Standard Grain | 1.0–2.0 µm | Low | Balanced toughness and hardness |

| Fine Grain | 0.6–1.0 µm | Medium | Higher hardness, better polishability |

| Sub-Micron | 0.2–0.5 µm | High | Excellent wear resistance, complex processing |

Finer grades require more precise milling, higher sintering temperatures, and stricter quality control, increasing cost but also improving service life.

Manufacturing Process Steps

The production of tungsten carbide bushings involves multiple complex steps — each adding value and cost.

| Process Stage | Description | Cost Impact |

|---|---|---|

| Powder Mixing | WC and binder powders blended uniformly | Low |

| Compacting / Pressing | Powder formed into “green” shape | Medium |

| Sintering | High-temperature furnace densifies carbide | High (energy-intensive) |

| Grinding & Lapping | Finishing to precise tolerance and Ra values | Very High (labor + diamond tooling) |

The grinding and lapping stage can account for over 30% of total manufacturing cost, especially for Ra 0.05 µm or better finishes.

Dimensional Tolerance and Precision Requirements

Tighter tolerances and smoother finishes increase both processing time and tool wear.

Bushings with ±0.002 mm tolerances or mirror-polished surfaces require multiple grinding passes and inspection steps.

If a customer specifies Ra 0.05 µm or better, lapping with diamond slurry and multiple measurement cycles are necessary — all adding cost but improving performance and reliability.

Coatings and Surface Treatments

Surface coatings are applied to enhance corrosion resistance, reduce friction, or improve wear life.

Each coating process adds material and labor costs but extends the bushing’s service life.

| Coating Type | Cost Impact | Main Benefit |

|---|---|---|

| TiN (Titanium Nitride) | Low | Improved hardness and wear resistance |

| CrN (Chromium Nitride) | Medium | Excellent corrosion resistance |

| DLC (Diamond-Like Carbon) | High | Ultra-low friction, long life in dry conditions |

Coatings can add 10–25% to the overall price but significantly improve performance in harsh environments.

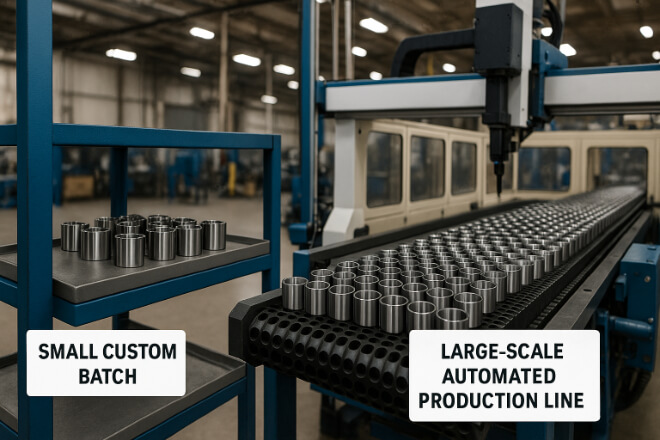

Order Quantity and Customization

Volume production lowers cost per unit due to economies of scale.

Small orders or custom designs require dedicated tooling, programming, and setup — increasing unit cost.

Factors that raise cost include:

Custom geometry or special hole patterns

Non-standard outer diameters or wall thicknesses

Small-batch prototypes (under 50 pcs)

Urgent or express delivery requests

Larger, recurring orders allow suppliers to amortize tooling and optimize production schedules, reducing cost by up to 30%.

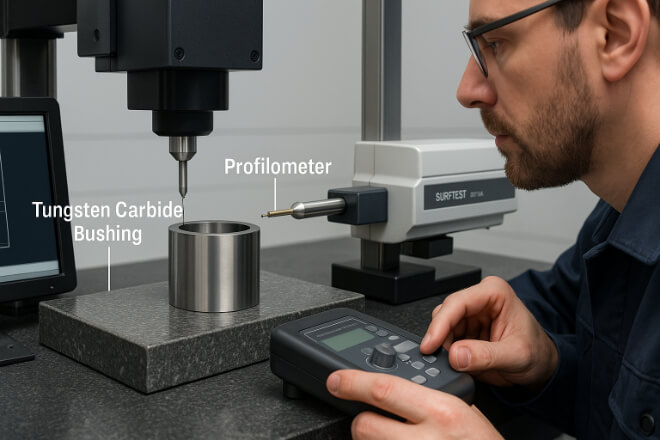

Quality Control and Testing

Advanced inspection systems — such as CMMs, profilometers, and ultrasonic testers — add labor and capital costs but ensure reliability in critical service.

For aerospace, oil & gas, and chemical processing, bushings must pass dimensional, surface, and microstructural testing.

Certified documentation such as material traceability and hardness reports also add administrative costs but are required for safety-critical industries.

Logistics, Origin, and Supplier Factors

The final cost also depends on where the bushings are made and how they’re delivered.

Manufacturing location: Labor and energy costs differ between countries.

Freight and tariffs: Export duties and long-distance shipping increase cost.

Lead time: Faster turnaround or air freight raises logistics cost.

Supplier capability: Established carbide manufacturers with in-house sintering and grinding can offer better pricing than traders or resellers.

When sourcing, buyers should compare total delivered cost, not just the ex-factory price.

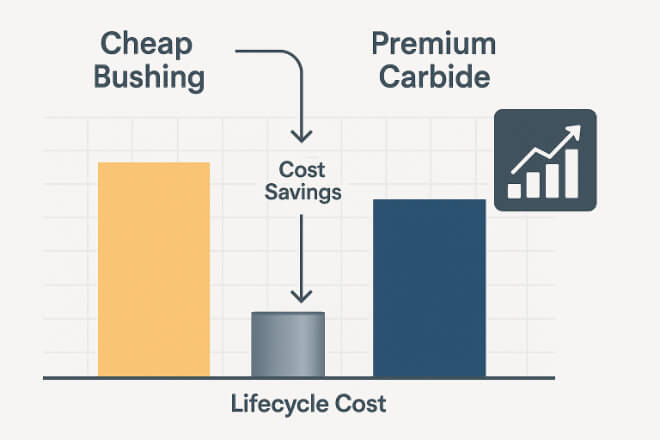

Long-Term Value vs. Initial Price

Sometimes, the lowest initial price leads to higher lifetime costs.

A cheaper bushing that wears out quickly can cause frequent shutdowns, seal leaks, or shaft wear — resulting in far higher repair expenses.

Choosing a higher-quality carbide with proper finish and coating can double service life, reducing total operating cost.

For decision-makers, the goal is not to buy the cheapest, but the most cost-effective over time.

Conclusion

The cost of tungsten carbide bushings depends on many interrelated factors — material composition, micrograin size, processing precision, coatings, and production volume.

Understanding these factors helps buyers make informed choices that balance performance, budget, and lifecycle efficiency.

Investing in consistent quality ensures longer uptime, fewer replacements, and better ROI for industrial equipment.

If you want to know more details about any company, please feel free to contact us.