Tungsten carbide bushings are renowned for their wear resistance and durability, making them ideal for high-performance applications.

However, to ensure optimal performance and lifespan, the hardness of the shaft that interacts with the bushing plays a critical role.

In this blog, we will discuss the recommended shaft hardness for tungsten carbide bushings, the factors influencing this choice, and how to select the right hardness for various industrial applications.

Why Shaft Hardness Matters for Tungsten Carbide Bushings

Shaft hardness refers to the ability of the shaft material to resist indentation, scratching, or deformation under load.

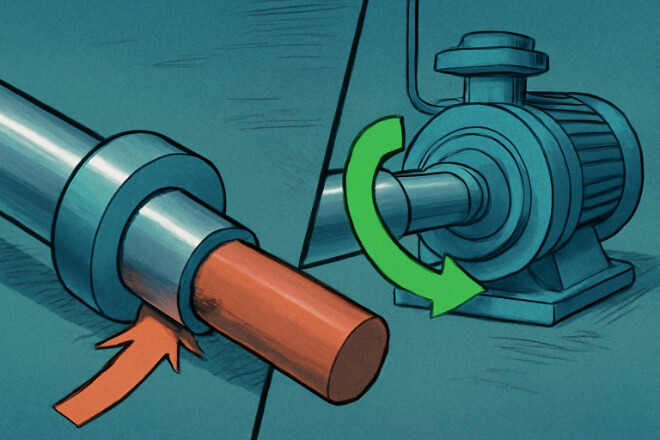

When a tungsten carbide bushing is installed on a shaft, both the bushing and the shaft are subjected to stresses, friction, and wear. The right shaft hardness is crucial for:

Preventing Excessive Wear:

If the shaft is too soft, it may wear down quickly, especially when paired with the hard tungsten carbide bushing.

On the other hand, if the shaft is too hard, it may cause the bushing to wear prematurely due to excessive friction.

Ensuring Proper Fit:

The hardness of the shaft helps maintain a proper fit between the bushing and the shaft. If the shaft is too soft, it may deform and cause misalignment.

Optimizing Performance:

Proper shaft hardness ensures that the bushing and shaft work together efficiently, reducing energy loss and improving the overall system’s performance.

Recommended Shaft Hardness for Tungsten Carbide Bushings

When selecting the shaft hardness for tungsten carbide bushings, it’s important to consider both the hardness of the bushing and the operating conditions.

Here’s a general guideline for the recommended shaft hardness:

Shaft Hardness of 45-55 HRC (Rockwell C Scale):

This is typically the ideal hardness for most applications where tungsten carbide bushings are used.

A shaft hardness in this range ensures a good balance between durability and wear resistance, allowing both the bushing and shaft to maintain their integrity over time.

For High-Load Applications:

In high-load environments where the shaft will experience higher stresses, a shaft hardness of 55-60 HRC may be more appropriate.

This provides increased wear resistance and ensures that the shaft holds up under heavy load conditions.

For Lower Load or Low-Speed Applications:

In applications with less demanding conditions, such as low-speed or low-load operations, a shaft hardness of 40-45 HRC may be sufficient.

This reduces the risk of excessive wear while maintaining compatibility with the tungsten carbide bushing.

Factors to Consider When Selecting Shaft Hardness

Several factors influence the choice of shaft hardness for tungsten carbide bushings:

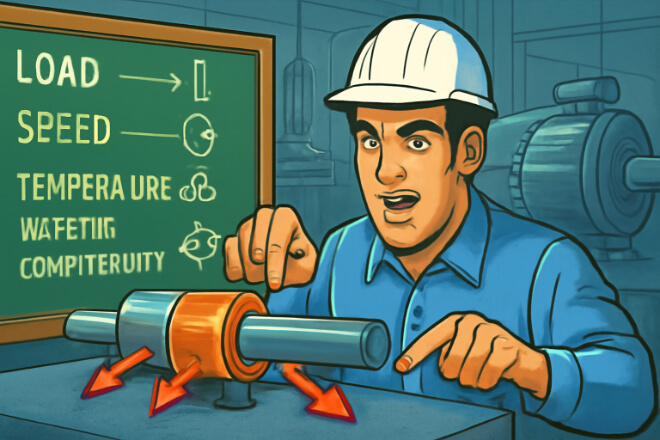

1). Operating Conditions

The operating environment of the bushing and shaft plays a significant role in determining the appropriate shaft hardness. These include:

Load: Higher loads require higher shaft hardness to avoid deformation and ensure the longevity of both the shaft and bushing.

Speed: High-speed applications may require slightly harder shafts to resist wear caused by friction.

Temperature: Elevated temperatures can affect the hardness of materials. If the system operates in high-temperature environments, it’s important to select materials that maintain their hardness at elevated temperatures.

2). Material Compatibility

When selecting the shaft hardness, it’s important to consider the material compatibility between the tungsten carbide bushing and the shaft. For instance:

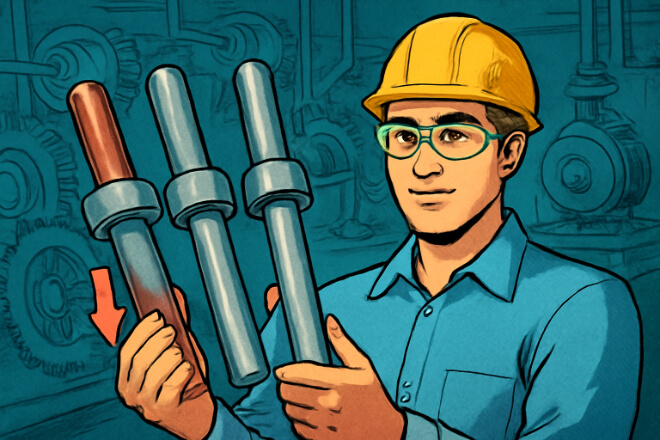

Mild Steel Shafts: Shafts made of mild steel typically have a hardness of 40-45 HRC and are suitable for less demanding applications.

Alloy Steel Shafts: Alloy steels, such as SAE 4140, are often used for shafts requiring higher hardness, typically in the range of 50-55 HRC.

Stainless Steel Shafts: Stainless steel shafts, particularly those made of higher grades like 17-4 PH or 316, often fall within the 45-55 HRC range, which works well with tungsten carbide bushings.

3). Wear Resistance Requirements

If the application demands extreme wear resistance, it is essential to balance the hardness of the shaft with the material properties of the tungsten carbide bushing.

For applications where frequent sliding and contact occur, a higher shaft hardness may be necessary to prevent excessive wear.

Shaft Hardness Guidelines for Different Applications

| Application Type | Recommended Shaft Hardness (HRC) | Material Compatibility |

|---|---|---|

| General Purpose | 45–55 HRC | Mild steel, stainless steel |

| High-Load Applications | 55–60 HRC | Alloy steels, hardened steels |

| Low-Speed/Low-Load | 40–45 HRC | Mild steel |

How to Achieve the Desired Shaft Hardness

Achieving the right shaft hardness involves several processes, depending on the material selected for the shaft:

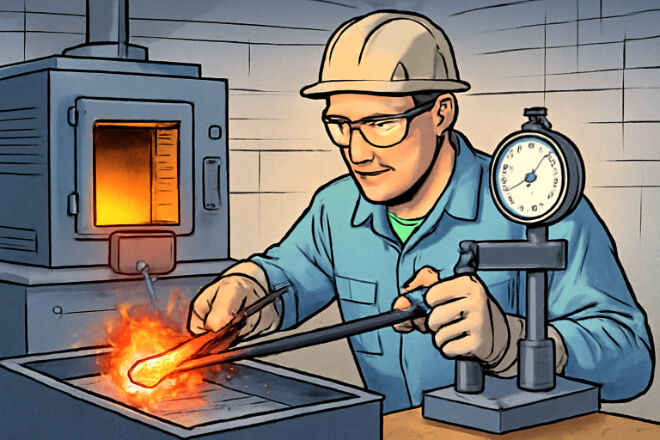

Heat Treatment:

Heat treatment processes like quenching and tempering can be used to increase the hardness of the shaft. These processes help to harden steel and other alloys to the desired level.

Surface Hardening:

In some cases, only the surface of the shaft needs to be hardened.

Techniques such as induction hardening or carburizing are commonly used for surface hardening to improve wear resistance without affecting the entire shaft.

Material Selection:

Choosing the right alloy or material from the start is crucial for achieving the desired hardness.

High-carbon steels or alloy steels often provide the necessary hardness for shafts that will be paired with tungsten carbide bushings.

The Importance of Maintaining the Right Hardness

Maintaining the correct shaft hardness throughout the operational life of the bushing is crucial for ensuring that the system continues to operate smoothly.

Regular inspections and maintenance can help identify signs of wear or damage that may be related to the shaft hardness.

If the shaft becomes too soft or too hard due to wear or environmental conditions, it could negatively affect the performance of the bushing.

Conclusion

Selecting the appropriate shaft hardness is essential for the optimal performance of tungsten carbide bushings.

By considering factors such as load, speed, material compatibility, and wear resistance, manufacturers can choose the right shaft hardness to ensure long-lasting and efficient operations.

Whether for general-purpose use, high-load environments, or low-speed applications, understanding and controlling shaft hardness is key to maximizing the lifespan and effectiveness of both the bushing and shaft.

If you want to know more details about any company, please feel free to contact us.