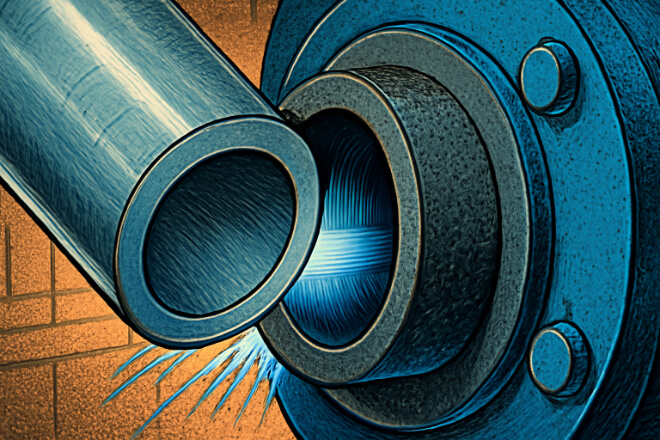

In mechanical systems, tungsten carbide bushings and pump shafts work together to ensure smooth, efficient performance.

One critical factor in their compatibility is the clearance fit, which refers to the space or gap between the bushing and shaft.

A proper clearance fit ensures that there is neither excessive friction nor too much movement, both of which can lead to premature wear or failure.

This blog will explore the importance of clearance fit in tungsten carbide bushings and pump shafts, why it matters, and how to use clearance fit charts to ensure the best performance for your equipment.

What Is Clearance Fit?

Clearance fit refers to the relationship between two mating parts—in this case, the tungsten carbide bushing and pump shaft—and the gap between them. This gap is crucial for the function and longevity of the system.

The clearance allows the parts to move smoothly without excessive friction, but too much clearance can lead to instability, while too little can cause wear and overheating.

1). Types of Clearance Fits:

Interference Fit: The shaft is slightly larger than the bushing, creating pressure between the parts. This can be used when tight, secure fitting is required.

Clearance Fit: The shaft is smaller than the bushing, allowing for free movement between the parts.

Transition Fit: A mix of both, where the shaft and bushing may either have slight interference or clearance depending on the tolerance.

2). Importance of Correct Clearance Fit:

Prevents Overheating: Proper clearance ensures smooth rotation and prevents friction that could lead to overheating.

Prevents Wear: Adequate clearance reduces wear on both the bushing and the shaft, leading to longer service life.

Improves Performance: Correct clearance ensures efficient operation, reducing energy consumption and downtime.

How Clearance Fits Affect Tungsten Carbide Bushings and Pump Shafts

Tungsten carbide bushings are commonly used in high-performance applications due to their hardness and wear resistance.

The fit between the bushing and pump shaft plays a significant role in the bushing’s performance.

Impact of Clearance Fit on Performance:

Too Little Clearance: If the clearance between the bushing and shaft is too tight, friction increases, which can lead to overheating, wear, and eventual failure.

Too Much Clearance: If there is too much clearance, the bushing can move excessively, leading to instability, noise, and even damage to other parts.

To achieve the best performance, it’s essential to ensure the proper clearance fit, which balances the friction and movement between the parts.

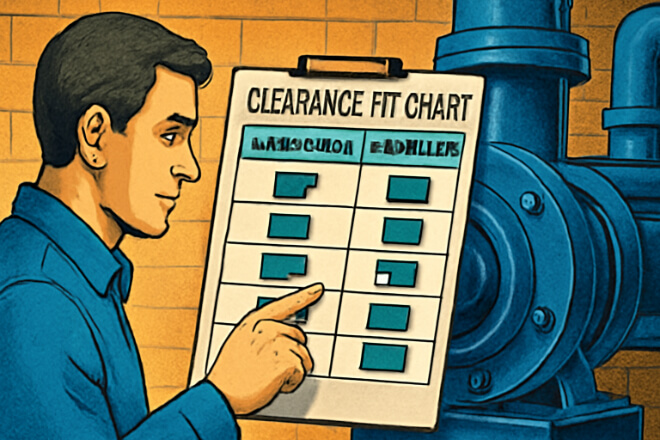

Understanding the Clearance Fit Chart

A clearance fit chart is a helpful tool used to determine the correct gap between the bushing and the pump shaft based on factors like the diameter, material, and operational conditions.

The chart typically provides the recommended tolerances for different shaft and bushing sizes, ensuring that the proper clearance is maintained.

1). How to Use a Clearance Fit Chart:

Identify the Shaft and Bushing Dimensions: Measure the diameter of both the shaft and the bushing to determine their sizes.

Consider the Operational Conditions: Take into account factors such as load, speed, and temperature that may influence the clearance needed.

Select the Appropriate Fit: Using the chart, choose the clearance fit that matches the required conditions. This will help you determine the ideal gap between the bushing and shaft.

2). Example of a Typical Clearance Fit Chart for Tungsten Carbide Bushings and Pump Shafts

| Shaft Diameter (mm) | Bushing Diameter (mm) | Recommended Clearance (mm) |

|---|---|---|

| 50 | 50.05 | 0.05 |

| 100 | 100.1 | 0.1 |

| 150 | 150.15 | 0.15 |

Factors to Consider When Selecting Clearance Fits

Selecting the appropriate clearance fit is not just about choosing the right numbers; several factors affect the overall performance of the system.

Below are key factors to consider when choosing clearance fits for tungsten carbide bushings and pump shafts:

Key Considerations:

Load and Pressure: High-load applications may require smaller clearance to maintain stability, while lower-pressure systems can tolerate larger clearances.

Speed: High-speed systems typically benefit from larger clearances to reduce heat buildup and prevent overheating.

Temperature: Temperature fluctuations can cause materials to expand or contract. Ensure the clearance fit can accommodate these changes without compromising performance.

Lubrication: Adequate lubrication is crucial for maintaining optimal clearance and reducing friction between the bushing and shaft.

Benefits of Proper Clearance Fit Selection

Ensuring the correct clearance fit between tungsten carbide bushings and pump shafts offers numerous benefits, including:

Key Benefits:

Extended lifespan: Proper clearance minimizes wear, which extends the life of both the bushing and shaft.

Reduced maintenance costs: By selecting the right clearance fit, you can reduce friction, wear, and damage, lowering maintenance needs and costs.

Increased efficiency: Properly fitting bushings and shafts operate more efficiently, reducing energy consumption and downtime.

Enhanced reliability: The correct clearance ensures smooth operation, reducing the risk of failure and system breakdowns.

Conclusion

Selecting the right clearance fit for tungsten carbide bushings and pump shafts is crucial for ensuring optimal performance and extending the life of your equipment.

By using a clearance fit chart and considering factors like load, speed, temperature, and lubrication, you can make an informed decision and improve the reliability of your systems.

Proper clearance fit selection leads to better wear resistance, reduced maintenance costs, and increased efficiency, ensuring the longevity of both your bushings and shafts.

If you want to know more details about any company, please feel free to contact us.