LNG (Liquefied Natural Gas) transfer pumps are crucial in transporting LNG at extremely low temperatures, which can create significant challenges for the materials used in pump components.

Tungsten carbide bushings are an ideal solution for these pumps due to their exceptional wear resistance, low thermal expansion, and durability at cryogenic temperatures.

This blog explores the importance of using tungsten carbide bushings in cryogenic LNG transfer pumps and how they help improve pump performance and lifespan.

Challenges in Cryogenic LNG Transfer Pump Applications

Cryogenic LNG transfer pumps operate in harsh environments, with temperatures reaching as low as -162°C (-260°F). These extreme conditions pose several challenges for pump components:

1). Low Temperature Wear

Traditional materials may experience brittleness at cryogenic temperatures, leading to increased wear and potential failure.

Tungsten carbide, however, retains its hardness and strength at low temperatures, reducing wear and ensuring reliable performance.

2). Thermal Expansion

As temperatures fluctuate, materials expand and contract. Tungsten carbide’s low thermal expansion rate makes it a reliable material for applications in cryogenic environments, where the risk of dimensional changes and misalignments is high.

3). Abrasive Wear

LNG can contain abrasive particles that wear down components over time. Tungsten carbide’s exceptional hardness allows it to withstand abrasive wear, maintaining the integrity of the bushings and preventing premature failure.

Why Tungsten Carbide Bushings Are Ideal for Cryogenic LNG Transfer Pumps

Tungsten carbide bushings provide numerous advantages in cryogenic LNG transfer pump applications. Here are the key reasons why they are the material of choice:

1). Exceptional Wear Resistance

Tungsten carbide bushings offer outstanding wear resistance, particularly in environments with abrasive particles.

This reduces the need for frequent replacements, lowering maintenance costs and increasing the pump’s lifespan.

2). High Strength at Low Temperatures

Unlike many materials that become brittle at low temperatures, tungsten carbide maintains its strength and toughness even in cryogenic conditions, ensuring that the bushings continue to function reliably.

3). Resistance to Thermal Expansion

Tungsten carbide has a low coefficient of thermal expansion, which means it experiences minimal expansion or contraction in response to temperature changes.

This makes tungsten carbide bushings less likely to deform or lose their fit, maintaining efficient pump operation.

Tungsten carbide exhibits excellent resistance to corrosion, which is important when handling LNG that may contain trace amounts of corrosive substances. This further increases the reliability of the bushings in cryogenic environments.

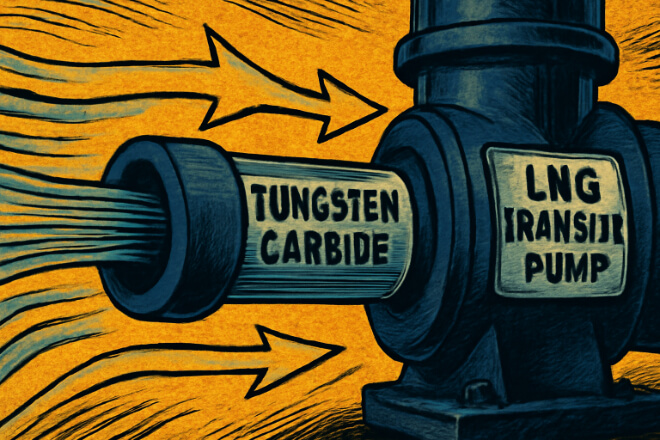

The Role of Tungsten Carbide Bushings in Enhancing Pump Performance

Tungsten carbide bushings contribute significantly to the performance of cryogenic LNG transfer pumps in the following ways:

1). Improved Pump Efficiency

By reducing wear and maintaining dimensional stability at low temperatures, tungsten carbide bushings help improve the overall efficiency of the pump.

This ensures that the pump operates at optimal performance levels with minimal friction and energy loss.

2). Longer Service Life

The durability of tungsten carbide ensures that bushings last longer than those made from conventional materials.

This reduces the frequency of maintenance, repairs, and replacements, allowing the LNG transfer pumps to run continuously for longer periods.

3). Reduced Maintenance Costs

Because tungsten carbide bushings are highly durable and resistant to wear and corrosion, the need for frequent maintenance is minimized.

This results in reduced downtime and maintenance costs, making it a cost-effective solution for LNG transfer operations.

Selecting the Right Tungsten Carbide Bushings for LNG Pumps

When selecting tungsten carbide bushings for cryogenic LNG transfer pumps, consider the following factors:

1). Material Composition

Tungsten carbide bushings can be made with different binder materials, such as cobalt (WC-Co) or nickel (WC-Ni).

The choice of binder material will depend on the specific operational requirements, such as the level of toughness and corrosion resistance needed.

2). Size and Tolerance

Ensure that the bushings meet the specific size and tolerance requirements of the LNG transfer pump. Proper fit is critical to preventing misalignment and ensuring smooth operation.

3). Performance Requirements

Consider the operating conditions, including temperature, pressure, and the presence of abrasive particles in the LNG. Choose tungsten carbide bushings that are designed to perform well in these conditions.

Conclusion

Tungsten carbide bushings are a crucial component in cryogenic LNG transfer pumps.

Their superior wear resistance, low thermal expansion, high strength at low temperatures, and corrosion resistance make them the ideal choice for these demanding applications.

By investing in tungsten carbide bushings, companies can enhance pump performance, reduce maintenance costs, and extend the lifespan of their LNG transfer pumps, ensuring efficient and reliable operation in extreme conditions.

If you want to know more details about any company, please feel free to contact us.