Tungsten carbide tips are widely known for their exceptional hardness and resistance to wear, making them indispensable in various industries, especially in cutting and drilling tools.

These tips are designed to perform in the most demanding environments, offering longer tool life and better performance compared to conventional materials.

In this blog, we will explore why tungsten carbide tips are considered the secret to superior hardness and wear resistance, highlighting their key advantages and applications.

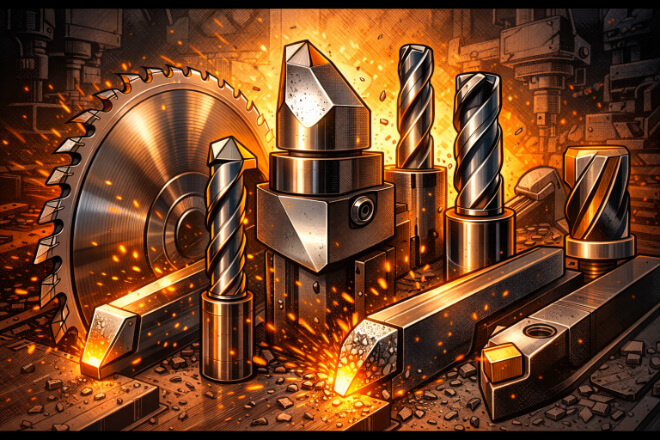

The Role of Tungsten Carbide in Industrial Tools

Tungsten carbide, a composite material made from tungsten and carbon, is renowned for its superior hardness.

It is one of the hardest materials known, second only to diamond. The key feature that makes tungsten carbide tips so popular is their ability to resist wear and abrasion in tough industrial environments.

When used in cutting, drilling, and grinding tools, they significantly improve the lifespan and performance of these tools.

Key Benefits:

High Hardness: Tungsten carbide tips can withstand extreme forces, making them ideal for cutting through hard materials like metal, stone, and concrete.

Improved Performance: Tools equipped with tungsten carbide tips maintain their sharpness and precision longer, reducing the need for frequent tool replacements.

Enhanced Durability: Tungsten carbide tips are resistant to heat, wear, and corrosion, ensuring reliable performance even under high temperatures and harsh conditions.

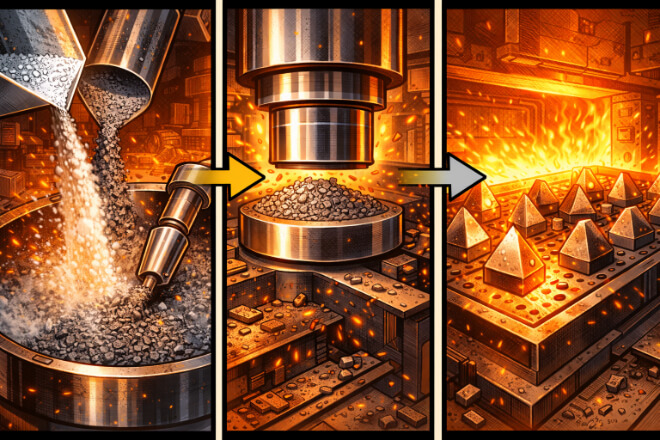

How Tungsten Carbide Tips Are Made

The process of manufacturing tungsten carbide tips is a precise and sophisticated operation.

It involves the combination of tungsten powder with carbon at high temperatures, creating a hard, dense material.

The mixture is then formed into the desired shape and sintered at high temperatures to achieve the required hardness and toughness.

Key Stages in the Manufacturing Process:

Powder Preparation: Tungsten powder is mixed with a binder material (commonly cobalt or nickel) to form a slurry.

Shaping: The slurry is then molded into the desired shape, typically in the form of small tips or inserts.

Sintering: The molded tips are heated in a furnace at high temperatures to form a solid, wear-resistant material.

Finishing: After sintering, the tips are ground and polished to their final shape and size.

This process ensures that each tungsten carbide tip meets the rigorous standards required for industrial use, offering superior hardness and resistance to wear.

Tungsten Carbide Tips in Various Applications

Tungsten carbide tips are used in a wide range of industries due to their unmatched wear resistance. Some of the most common applications include:

Oil and Gas Drilling: Tungsten carbide tips are used in drill bits and other downhole tools due to their ability to handle extreme pressure, temperature, and abrasion.

Mining: In mining operations, tungsten carbide tips are used in tools like rock drills and tunneling equipment, where durability and high wear resistance are essential.

Metal Cutting: Tungsten carbide tips are commonly found in cutting tools such as saw blades, end mills, and lathe tools. These tips enhance cutting efficiency and prolong tool life.

Construction: Tungsten carbide tips are used in construction tools like concrete cutters, road planers, and trenching equipment due to their ability to handle hard materials.

Table: Applications of Tungsten Carbide Tips

| Industry | Applications |

|---|---|

| Oil and Gas | Drill bits, downhole tools |

| Mining | Rock drills, tunneling equipment |

| Metal Cutting | Cutting tools (saw blades, end mills, lathe tools) |

| Construction | Concrete cutters, road planers, trenching tools |

Why Tungsten Carbide Tips Are Superior to Other Materials

While other materials, like high-speed steel and ceramics, are also used in industrial applications, tungsten carbide stands out due to its unique combination of hardness, toughness, and wear resistance.

Hardness: Tungsten carbide’s hardness allows it to maintain sharp edges longer than other materials, leading to fewer tool changes.

Wear Resistance: Tungsten carbide tips excel at resisting abrasion, making them ideal for use in environments with high friction and wear.

Temperature Resistance: Tungsten carbide can withstand high temperatures without losing its hardness, making it perfect for applications involving heat.

The Impact of Grain Size on Tungsten Carbide Tips

The grain size of tungsten carbide tips plays a crucial role in their performance. Finer grains lead to greater hardness, while larger grains increase toughness.

Choosing the right grain size depends on the application—fine grains are preferred for high-precision cutting, while larger grains are ideal for applications involving heavy impact.

Table: Impact of Grain Size

| Grain Size | Characteristics | Ideal Applications |

|---|---|---|

| Fine Grain | Harder, more wear-resistant | High-precision cutting, drilling |

| Coarse Grain | Tougher, less brittle | Heavy impact, mining, drilling |

Conclusion

Tungsten carbide tips are the backbone of modern industrial tools, offering unmatched hardness and wear resistance.

Their versatility and durability make them ideal for a range of applications, from drilling and cutting to mining and construction.

By understanding the benefits of tungsten carbide and its manufacturing process, industries can make informed decisions to improve the efficiency and longevity of their tools.

If you want to know more details about any company, please feel free to contact us.