Tungsten carbide tips are widely used in industries such as drilling, mining, and machining, thanks to their remarkable hardness and wear resistance.

However, the performance of tungsten carbide tips depends not only on the carbide itself but also on the binder material used in its composition.

Cobalt and nickel are the two most commonly used binders, each offering distinct advantages and disadvantages.

In this blog, we will explore the differences between cobalt and nickel binders in tungsten carbide tips, helping industrial decision-makers understand which binder is best suited for their specific applications.

What Are Tungsten Carbide Binders?

Before diving into the comparison, it’s important to understand the role of binders in tungsten carbide.

The binder is the material that holds the tungsten carbide grains together, providing the final product with strength and toughness. The binder helps the material resist fractures and improves its overall mechanical properties.

Cobalt and nickel are the most common binder materials used in tungsten carbide tips, and both offer different benefits depending on the application.

1). Cobalt Binders:

Cobalt is the most traditional binder used in tungsten carbide.

It provides excellent wear resistance and high toughness, making it ideal for many industrial applications, including cutting, mining, and drilling. Cobalt also enhances the material’s ability to withstand high temperatures.

2). Nickel Binders:

Nickel, on the other hand, offers excellent corrosion resistance and higher resistance to oxidation, making it particularly valuable in environments where exposure to moisture or chemicals is a concern.

Nickel-based tungsten carbide is often used in industries such as oil and gas, where tools are exposed to harsh environmental conditions.

Cobalt vs. Nickel Binders: Performance Comparison

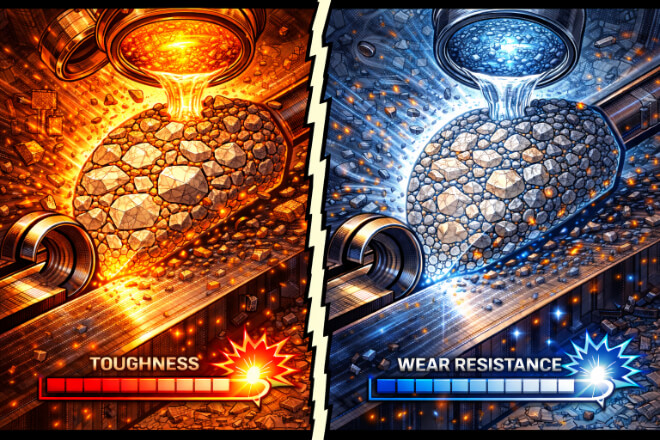

When deciding between cobalt and nickel binders for tungsten carbide tips, it’s crucial to compare their performance across several key factors, including wear resistance, toughness, heat resistance, and corrosion resistance.

1). Wear Resistance

Cobalt Binders:

Cobalt-based tungsten carbide has excellent wear resistance, particularly in high-impact applications.

Its hardness and strength allow it to maintain its shape under heavy wear and tear.

Nickel Binders:

Nickel-based binders also offer strong wear resistance, but they perform better in low- to moderate-impact environments.

They are slightly less wear-resistant than cobalt, but their corrosion resistance compensates for this in many applications.

2). Toughness

Cobalt Binders:

Cobalt provides better toughness and impact resistance compared to nickel. This makes cobalt a better choice for high-stress environments where the material is subjected to heavy impact or vibration.

Nickel Binders:

While nickel is less tough than cobalt, it still provides a good level of toughness, particularly in applications that do not require high-impact resistance.

Nickel’s main strength lies in its resistance to corrosion, rather than its toughness.

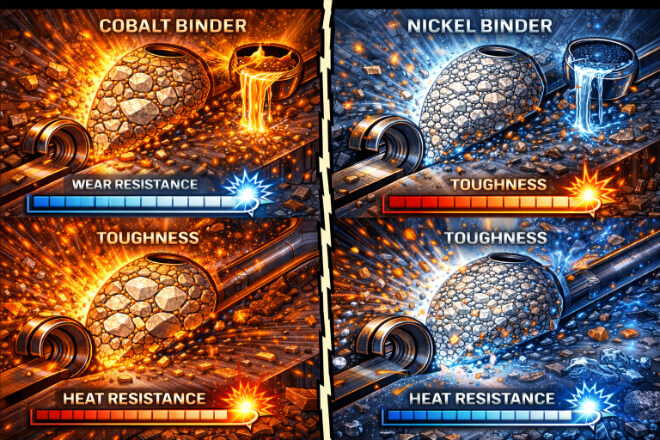

3). Heat Resistance

Cobalt Binders:

Cobalt has a higher heat tolerance than nickel, which allows cobalt-bonded tungsten carbide to maintain its hardness at elevated temperatures.

This is particularly useful in applications like cutting and drilling, where high temperatures are generated.

Nickel Binders:

Nickel-bonded tungsten carbide has lower heat resistance compared to cobalt, but it still performs well in moderate-temperature environments.

It is often used in industries where high heat is not a major concern.

Cobalt Binders:

Cobalt is prone to oxidation and corrosion, particularly in acidic or humid environments.

While cobalt-bonded tungsten carbide is highly durable, its performance may degrade over time when exposed to harsh chemicals or moisture.

Nickel Binders:

Nickel excels in corrosion resistance, making it ideal for use in environments where tools are exposed to moisture, acids, or other corrosive substances.

Nickel-based tungsten carbide is commonly used in the oil and gas industry, where equipment is exposed to corrosive fluids.

When to Choose Cobalt vs. Nickel Binders

The choice between cobalt and nickel binders depends on the specific requirements of the application. Let’s take a look at some common scenarios:

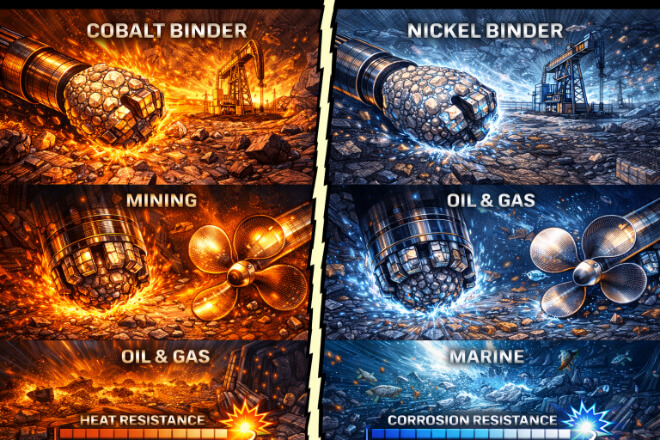

1). Applications for Cobalt-Bonded Tungsten Carbide:

Mining Tools: Cobalt is ideal for mining tools like rock drills and drilling bits, as these tools require both wear resistance and toughness to handle hard rocks and heavy impact.

Cutting Tools: Cobalt-based tungsten carbide is commonly used in industrial cutting tools like lathe inserts, milling cutters, and saw blades, where wear resistance and heat resistance are crucial.

High-Temperature Environments: Cobalt’s superior heat resistance makes it a good choice for applications where high temperatures are generated, such as cutting and grinding.

2). Applications for Nickel-Bonded Tungsten Carbide:

Oil and Gas Drilling:

Nickel-bonded tungsten carbide is ideal for oil and gas applications due to its excellent corrosion resistance.

It performs well in downhole tools and equipment exposed to harsh chemicals and high humidity.

Chemical Processing:

In industries where equipment is exposed to acidic or corrosive environments, nickel-bonded tungsten carbide can provide enhanced longevity and reliability.

Marine Applications:

Nickel’s resistance to corrosion makes it suitable for marine equipment, such as pumps and propellers, that operate in saltwater environments.

Table: Cobalt vs. Nickel Binders in Tungsten Carbide

| Property | Cobalt Binder | Nickel Binder |

|---|---|---|

| Wear Resistance | Excellent wear resistance, ideal for high-impact applications | Good wear resistance, better in low-impact environments |

| Toughness | Better toughness and impact resistance | Moderate toughness, better for low-impact applications |

| Heat Resistance | Higher heat resistance, ideal for high-temperature applications | Lower heat resistance, suitable for moderate-temperature environments |

| Corrosion Resistance | Prone to oxidation and corrosion in harsh environments | Excellent corrosion resistance, ideal for harsh chemical and marine environments |

Conclusion

When it comes to tungsten carbide tips, the choice between cobalt and nickel binders plays a significant role in the performance of the material.

Cobalt binders offer better toughness, wear resistance, and heat resistance, making them suitable for high-impact and high-temperature applications.

On the other hand, nickel binders provide superior corrosion resistance, making them the better choice for environments exposed to moisture, chemicals, and corrosive substances.

By understanding the strengths and weaknesses of each binder, industrial decision-makers can make informed choices that optimize the performance of their tools and equipment.

If you want to know more details about any company, please feel free to contact us.