When it comes to industrial milling and shaping of hard metals, choosing the right cutting tools is essential for ensuring precision, efficiency, and long tool life.

Tungsten carbide tips are widely regarded as the best option for these applications due to their exceptional hardness, wear resistance, and heat resistance.

In this blog, we’ll explore how tungsten carbide tips improve milling and shaping operations for hard metals, including their advantages, applications, and cost-effectiveness.

1. Why Tungsten Carbide Tips Are Essential for Milling and Shaping Hard Metals

Milling and shaping hard metals such as steel, titanium, and alloys can cause significant wear and tear on tools.

Tungsten carbide tips are an ideal solution for these demanding applications because they maintain cutting performance even under extreme pressure and temperature.

Key Benefits of Tungsten Carbide Tips:

High Hardness: Tungsten carbide is one of the hardest materials, making it perfect for cutting through tough metals.

Wear Resistance: It resists wear better than other materials, allowing for longer tool life and consistent performance.

Heat Resistance: Tungsten carbide can handle high temperatures generated during cutting, which prevents softening or damage.

Durability: The material’s toughness helps resist cracking or chipping, even when subjected to high impact and stress.

These properties make tungsten carbide tips essential for maintaining productivity and achieving accurate results when milling or shaping hard metals.

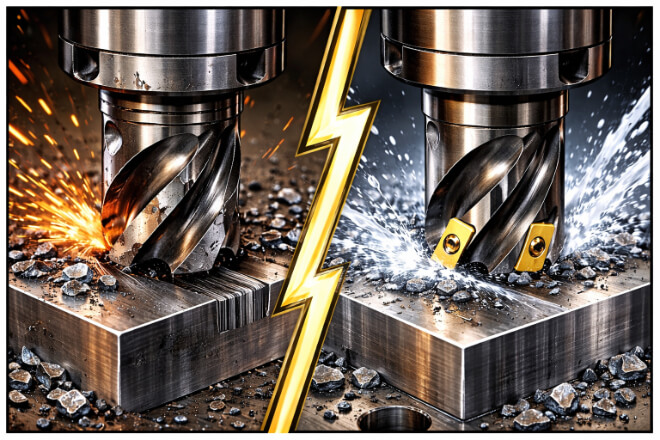

2. How Tungsten Carbide Tips Improve Cutting Efficiency

Cutting efficiency is crucial in industrial milling operations. Tungsten carbide tips contribute to faster cutting, smoother finishes, and higher productivity.

Their ability to withstand high cutting speeds and reduce wear ensures that milling machines can perform at optimal levels.

How Tungsten Carbide Enhances Cutting Efficiency:

Higher Cutting Speeds: Tungsten carbide tips allow for faster cutting speeds without sacrificing tool life or cutting performance.

Consistent Cutting Performance: The hardness and stability of tungsten carbide help maintain sharp cutting edges, leading to consistent and precise cuts.

Reduced Tool Wear: Tungsten carbide resists abrasive materials and reduces the need for frequent tool replacements, improving overall efficiency.

By enabling higher cutting speeds and reducing tool wear, tungsten carbide tips help industrial milling operations achieve better results in less time, making them more cost-effective.

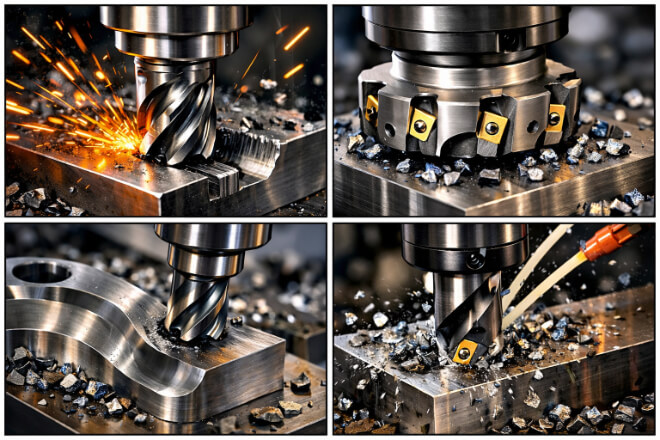

3. Applications of Tungsten Carbide Tips in Industrial Milling

Tungsten carbide tips are widely used in various industrial milling and shaping applications, particularly for hard metals.

These tips are ideal for tasks that require high precision, durability, and resistance to extreme conditions.

Common Applications Include:

Milling Steel: Tungsten carbide tips are used in milling machines to cut through steel and other tough alloys efficiently, reducing tool wear and extending tool life.

CNC Machining: Carbide tips are essential for CNC machines that mill and shape metals with high precision, ensuring smooth surface finishes and accurate dimensions.

Precision Drilling: Carbide-tipped drills are used for precise hole drilling in hard metals, ensuring minimal wear and clean, accurate holes.

Shaping Tough Alloys: When shaping high-strength alloys like titanium, tungsten carbide tips help reduce heat generation and maintain cutting edge stability.

By selecting tungsten carbide tips for these applications, manufacturers can improve production quality and efficiency.

4. Why Tungsten Carbide Tips Provide Long-Term Cost Savings

Although tungsten carbide tips come with a higher initial cost, they provide long-term cost savings by reducing the frequency of tool replacements and minimizing downtime.

The durability and wear resistance of tungsten carbide help extend the life of cutting tools, allowing businesses to achieve better returns on investment.

Cost Benefits of Tungsten Carbide Tips:

Reduced Tool Replacement Frequency: Tungsten carbide’s exceptional hardness and wear resistance mean tools last longer, reducing the need for frequent replacements.

Lower Maintenance Costs: Carbide tips require less maintenance and sharpening, which cuts down on labor and tool servicing costs.

Increased Productivity: With longer tool life and faster cutting speeds, production time is reduced, leading to more efficient machining processes.

The long-lasting nature of tungsten carbide tips helps companies save money in the long run, despite the higher upfront cost.

5. Managing Tool Wear in Milling Operations

Tool wear is a significant concern in milling operations, particularly when working with hard metals.

Tungsten carbide tips help manage wear by maintaining sharp cutting edges for longer, reducing the need for frequent tool changes and ensuring smoother cuts.

Ways Tungsten Carbide Reduces Tool Wear:

Resistant to Abrasive Materials: Tungsten carbide’s resistance to abrasive metals ensures that the tool maintains its shape and cutting ability, even when dealing with tough materials.

Reduced Friction: Carbide tips reduce friction during cutting, preventing excessive heat buildup and wear on the cutting edges.

Stable Cutting Edge: The material’s durability allows the cutting edge to remain stable over time, minimizing the need for re-sharpening and improving cutting precision.

Managing tool wear with tungsten carbide tips helps maintain operational efficiency and reduces the total cost of ownership for cutting tools.

6. The Role of Tungsten Carbide Tips in Precision and Accuracy

In industrial milling, achieving precise and accurate cuts is critical.

Tungsten carbide tips are designed to provide stable cutting action, reducing vibrations and ensuring that the finished product meets high-quality standards.

How Tungsten Carbide Improves Precision:

Stable Cutting Forces: Tungsten carbide tips maintain stable cutting forces, reducing vibrations and improving cutting accuracy.

Sharper Cutting Edges: The hardness of tungsten carbide ensures that the cutting edge remains sharp for longer, allowing for precise cuts in hard metals.

Less Deformation: Carbide tips are less prone to deformation, ensuring that the milling tool maintains its shape and cutting ability during prolonged use.

By using tungsten carbide tips, manufacturers can achieve high precision and consistent quality in their milling operations.

7. Selecting the Right Tungsten Carbide Tip for Specific Applications

Choosing the right tungsten carbide tip for industrial milling depends on various factors, such as the type of material, cutting speed, and depth of cut.

Selecting the correct tip is essential for achieving optimal performance and minimizing tool wear.

Factors to Consider When Selecting Tungsten Carbide Tips:

Material Hardness: Harder metals like titanium and stainless steel require tips with higher wear resistance.

Cutting Speed: High-speed operations require carbide tips that can handle the increased friction and heat.

Depth of Cut: Deeper cuts require more robust carbide tips that can withstand higher cutting forces.

Understanding these factors helps decision-makers select the appropriate carbide tips for their specific milling needs, ensuring better performance and tool longevity.

8. Applications of Tungsten Carbide Tips in Other Industrial Tools

Tungsten carbide tips are not only used in milling tools but also in a wide range of other industrial tools that require high precision and durability.

Other Applications of Tungsten Carbide Tips:

Turning Tools: Tungsten carbide is widely used in turning tools for shaping metal parts with high accuracy and stability.

Grinding Wheels: Carbide tips are used in grinding wheels to sharpen and finish metal parts with precision.

Tapping Tools: Tungsten carbide tips help create precise threads in metal workpieces, ensuring durability and accuracy.

The versatility of tungsten carbide tips across various tools makes them essential for industrial manufacturing processes.

Conclusion

Tungsten carbide tips are an indispensable part of industrial milling and shaping hard metals.

Their hardness, wear resistance, and heat stability make them ideal for handling tough materials with precision and efficiency.

By choosing the right tungsten carbide tips, businesses can improve productivity, reduce costs, and extend the life of their milling tools.

Whether you are working with steel, titanium, or other tough alloys, tungsten carbide tips ensure high performance and consistent results in industrial milling applications.

If you want to know more details about any company, please feel free to contact us.