What is Hardness?

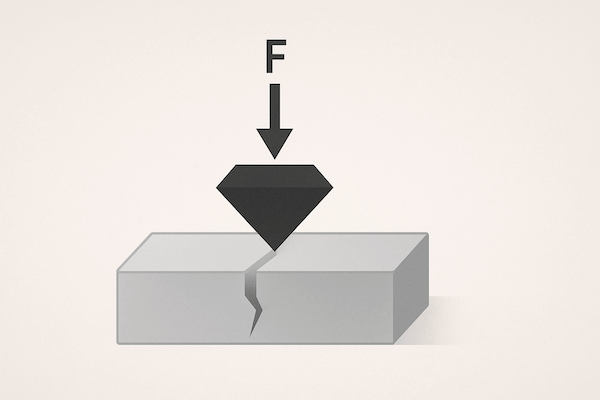

Hardness is the measure of a material’s resistance to permanent deformation, particularly indentation, scratching, or cutting. In practical terms, it describes how well a material can resist forces that attempt to dent, scratch, or wear it.

Hardness is not a single absolute value; it varies based on the testing method used. Common hardness tests include:

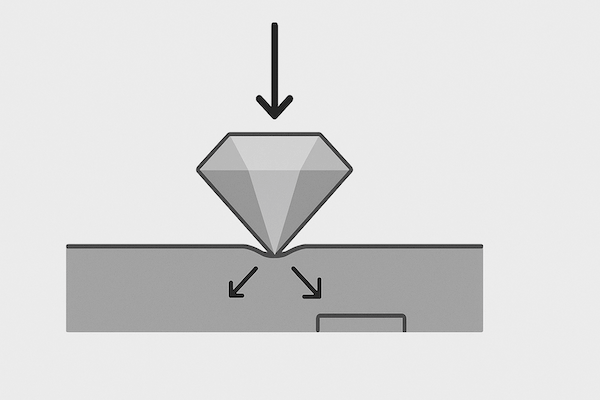

Vickers (HV) – uses a diamond pyramid indenter

Rockwell (HRA) – common in cemented carbide rating

Brinell (HB) – used for softer metals

Mohs scale – qualitative scale from 1 (talc) to 10 (diamond)

Tungsten carbide typically ranks extremely high on all these scales, often near 1500–2000 HV or 88–94 HRA.

Why is Hardness Important?

In industrial and manufacturing settings, hardness directly affects how a tool:

Resists wear from abrasion or contact with rough surfaces

Maintains dimensional accuracy over prolonged use

Survives high-pressure and high-heat conditions without deformation

For carbide cutting tools, hardness ensures sharp edges stay intact. For wear parts, it means minimal surface erosion and longer service life.

Hardness in Tungsten Carbide (Cemented Carbide)

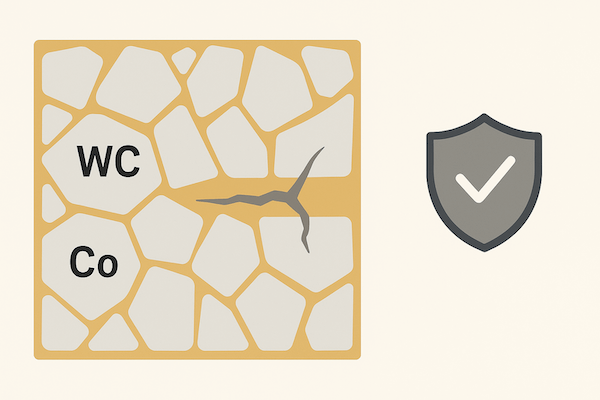

Tungsten carbide is a composite material made of:

Hard tungsten carbide (WC) grains, and

A metallic binder, usually cobalt (Co) or nickel (Ni)

The WC grains provide extreme hardness, while the binder offers toughness. This combination creates cemented carbide, which is both very hard and relatively tough—ideal for tooling.

Typical hardness ranges:

| Grade | Cobalt Content (%) | Hardness (HRA) |

|---|---|---|

| YG6 | 6% | ~91.5 – 92.5 |

| YG8 | 8% | ~89.5 – 91.0 |

| YG20 | 20% | ~85.0 – 87.0 |

Generally, lower binder content = higher hardness, but with reduced toughness.

What Affects Hardness in Carbide?

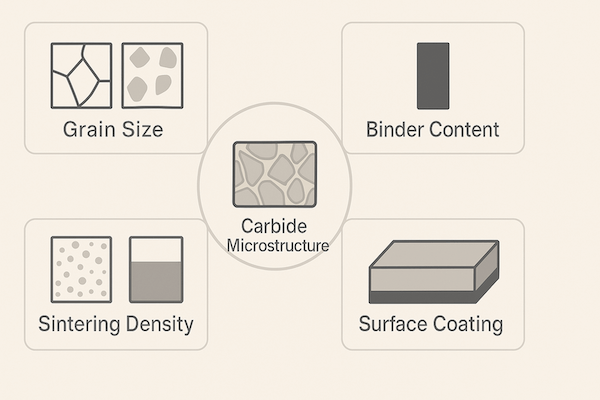

Several factors determine the final hardness of a tungsten carbide part:

▸ Grain Size

Fine WC grains increase hardness by creating a dense and uniform structure. Ultrafine grades are used for micro-cutting and precision tooling.

▸ Binder Content

Less cobalt means higher hardness, but with lower toughness. Optimal balance is crucial for performance.

▸ Sintering Quality

Proper sintering at high temperature ensures minimal porosity, enhancing hardness and strength.

▸ Surface Coatings

Advanced coatings (like TiAlN or diamond coatings) boost surface hardness even further—especially for high-speed cutting tools.

Applications That Rely on High Hardness

Hardness is a defining property in many tungsten carbide tool applications, including:

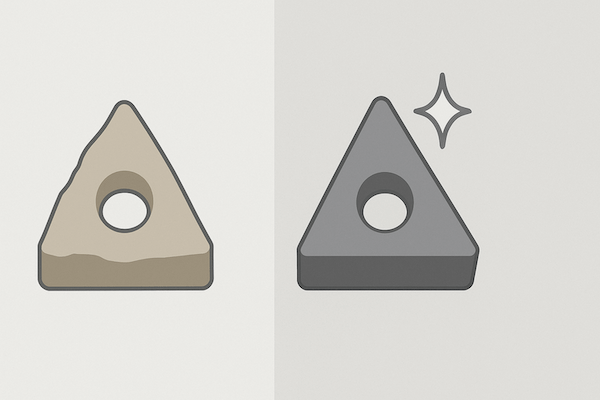

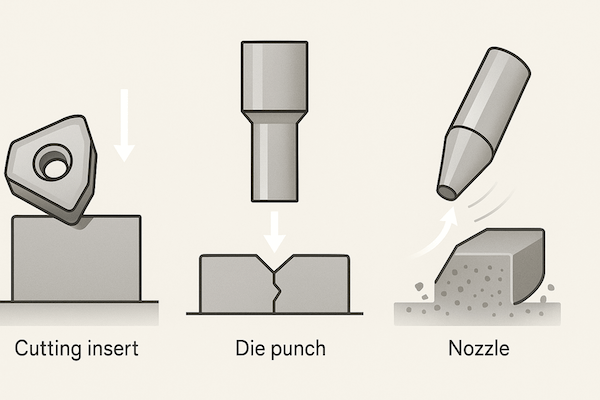

Metal cutting tools – inserts, end mills, drills

Woodworking tools – saw tips, planer blades

Mold and die components – punches, dies, core pins

Mining tools – drill bits, picks, cutters

In all these applications, a harder tool equals longer life and better performance.

Testing Methods for Carbide Hardness

Carbide tools are most commonly tested using:

Rockwell A scale (HRA) – specifically suited for hard materials

Vickers test (HV30 or HV50) – measures diagonal indentation size

Microhardness testing – for coatings and thin layers

Tested samples must have a smooth, polished surface and sufficient thickness for reliable results.

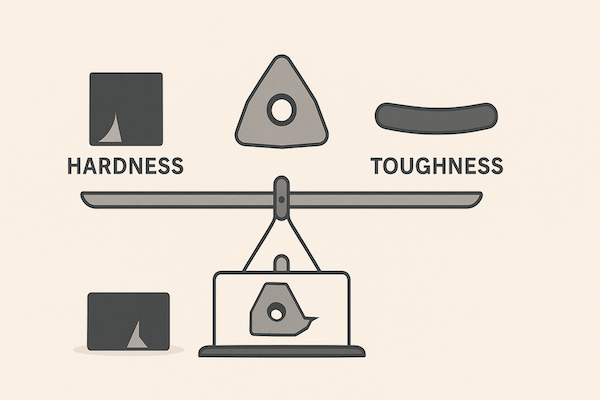

Hardness vs. Toughness – The Classic Trade-off

A key challenge in material engineering is balancing hardness and toughness:

High hardness → superior wear resistance, but risk of brittleness

High toughness → better impact resistance, but more wear

For carbide tools, manufacturers optimize this balance based on the application. For example:

Cutting inserts for steel require high hardness

Mining picks need more toughness

Micro drills require ultrafine grains and moderate hardness

Conclusion

Hardness is a cornerstone of tungsten carbide performance. Whether it’s resisting wear, maintaining cutting precision, or surviving high-speed operation, high hardness ensures that tungsten carbide tools meet the rigorous demands of modern industries. By controlling grain size, binder ratio, and coatings, engineers can tailor carbide hardness for almost any use case—delivering tools that are sharp, strong, and built to last.