Tungsten carbide tools are valued for their extreme hardness, high wear resistance, and long service life—but what makes these properties possible? The answer lies in their carbide composition. This term refers to the specific combination of materials used to form the tool, which directly influences its mechanical, chemical, and thermal performance.

This article will explain what carbide composition is, why it matters, and how different elements affect the behavior of cemented carbide tools.

What Is Carbide Composition?

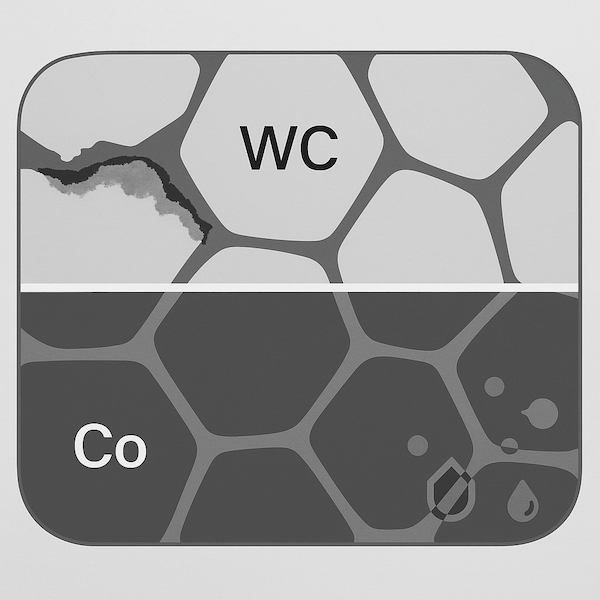

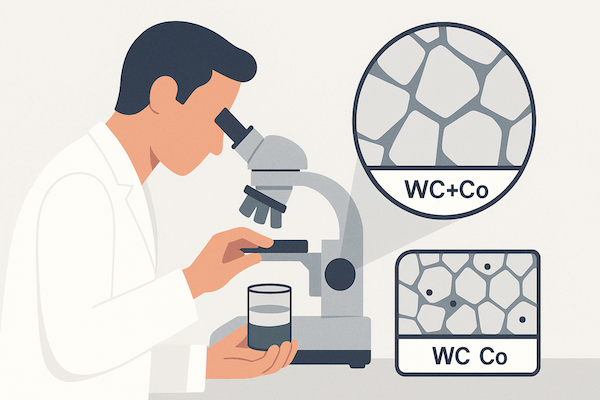

Carbide composition describes the ratio and types of materials present in a cemented carbide product. These tools are not made from pure tungsten carbide (WC) alone—instead, they are composites, made by mixing:

WC (Tungsten Carbide) grains – the primary hard phase

Binder metal, typically Cobalt (Co) or Nickel (Ni) – which holds the WC grains together

Alloying elements, such as Vanadium (V), Chromium (Cr), Tantalum (Ta) – to modify microstructure and performance

The exact proportions of these materials are carefully engineered to meet the demands of different cutting, forming, and wear-resistant applications.

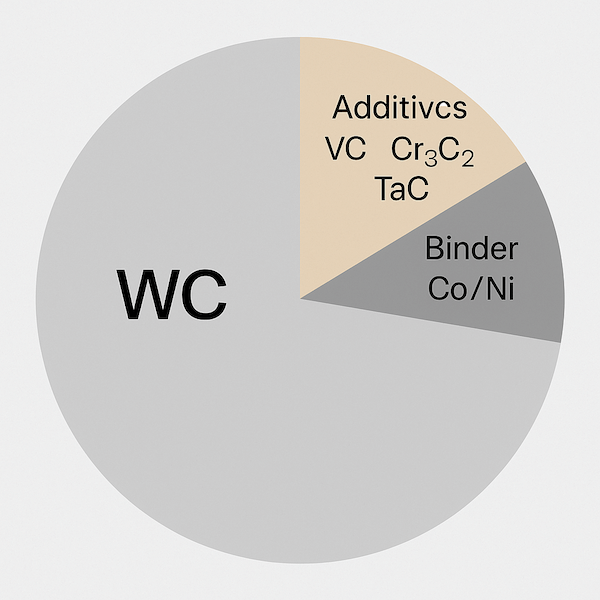

Typical Composition Breakdown

| Component | Function | Typical Content (wt%) |

|---|---|---|

| WC (Tungsten Carbide) | Provides hardness and wear resistance | 70–97% |

| Co or Ni (Binder) | Provides toughness and holds grains together | 3–30% |

| VC, Cr₃C₂, TaC (Additives) | Control grain size, improve corrosion/oxidation resistance | 0.1–3% |

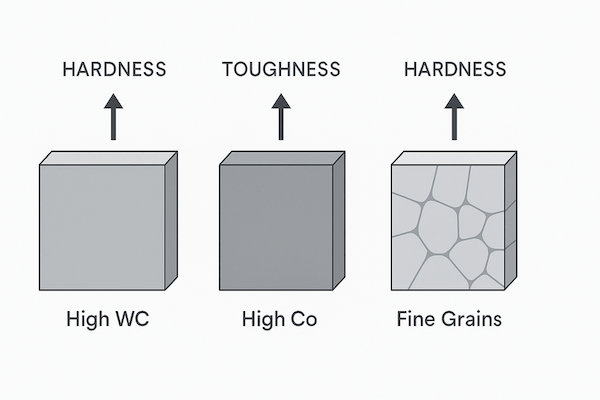

How Composition Affects Tool Performance

Different carbide compositions result in different tool characteristics. For example:

Higher WC content → Greater hardness and wear resistance, but lower toughness

More binder (Co/Ni) → Increased toughness, but reduced hardness

Finer WC grains (controlled by additives) → Higher edge stability and surface finish

Cr or Mo additives → Improve chemical stability and prevent binder leaching in wet or corrosive environments

Each application—whether it’s high-speed steel cutting, oil drilling, or precision machining—requires a carefully tailored composition to balance hardness, toughness, and chemical resistance.

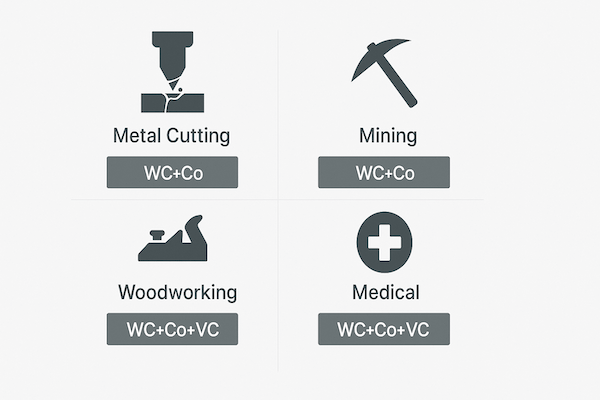

Examples of Composition for Various Applications

| Application | Composition Focus |

|---|---|

| Metal Cutting Inserts | Submicron WC, ~6–10% Co, grain inhibitors |

| Mining Tools | Coarse WC, 10–15% Co, high impact resistance |

| Woodworking Tools | Fine WC, 6–10% Co, edge wear resistance |

| Medical/Corrosive Use | WC with Ni binder, Cr/Mo alloying for stability |

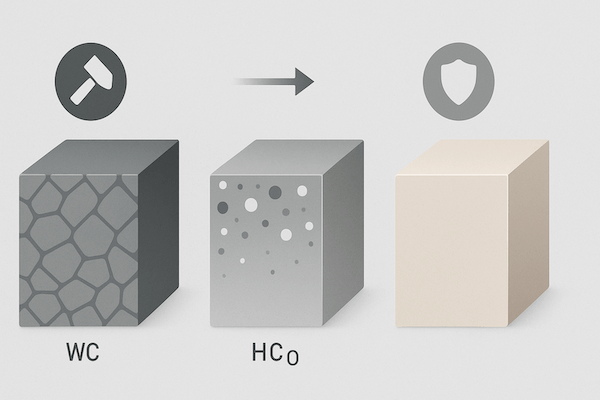

Why Composition Control Matters

Precise control over carbide composition ensures:

Consistent mechanical properties

Predictable tool life and performance

Customizability for different industries

Resistance to thermal cracking, erosion, and corrosion

Without proper composition control, tools may fail prematurely or underperform in critical tasks.

Conclusion

Carbide composition is the foundation of every tungsten carbide tool’s performance. It determines how hard, tough, chemically stable, or wear-resistant the tool will be. From heavy-duty mining bits to delicate micro-end mills, understanding and optimizing carbide composition is essential for achieving tool reliability, efficiency, and longevity.

Whether you’re a manufacturer, engineer, or buyer, knowing how carbide composition works gives you the power to choose the right tool for the right job.