Grinding, Machining & Polishing Capabilities

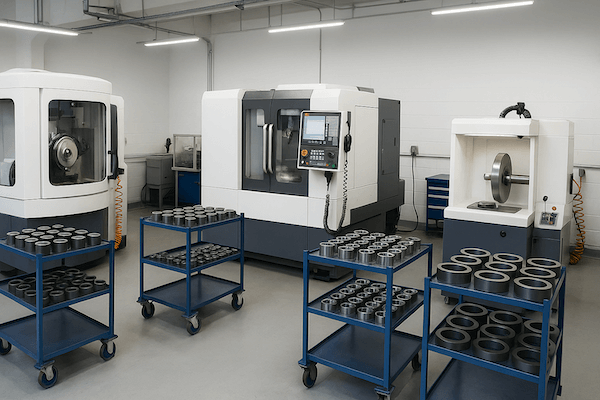

As a leading tungsten carbide tool manufacturer, we combine advanced grinding, precision machining, and high-fidelity polishing to deliver carbide tools that meet the strictest performance and durability demands. Below we explain each process, showcase our equipment and know-how, and provide educational image prompts for visual illustration.

Expertise in Grinding, Machining and Polishing

Retop Carbide is renowned for its high-quality grinding, machining, and polishing of tungsten carbide parts.

Key Equipment

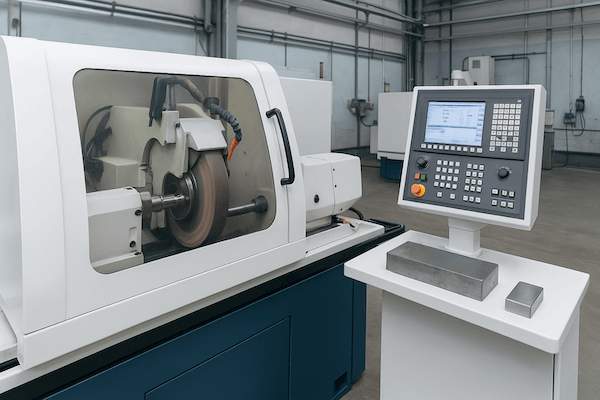

- OD/ID Cylindrical Grinder: External and internal diameter grinding of shafts, collars, and bore features.

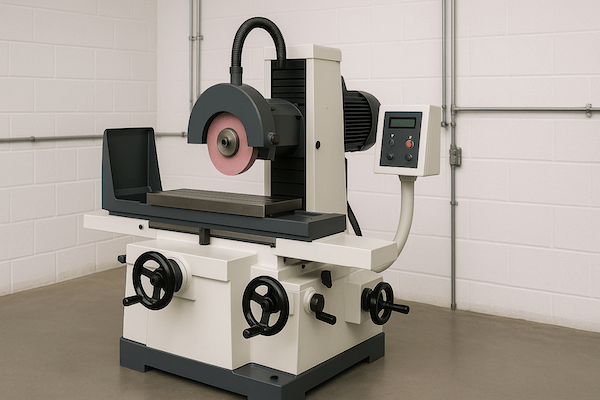

- Surface Grinder: Precision flat grinding of tool faces and base surfaces.

- Centerless Grinder: Continuous, high-throughput grinding of bar stock to tight diameters.

- CNC Tool Grinder: Multi-axis grinding for complex chip-breaker, chamfer, and contour profiles.

- Belt/Disc Grinder: Rapid, coarse removal for pre-grinding and deburring.

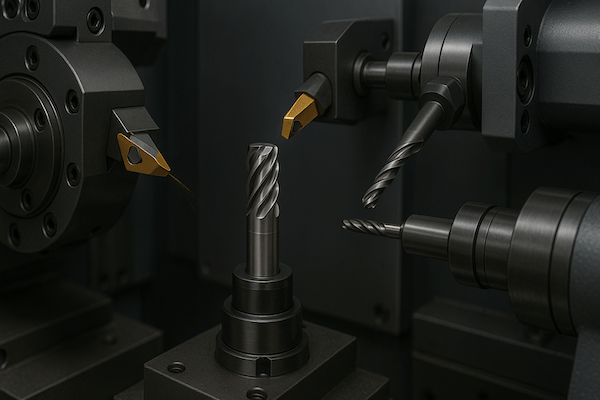

- CNC Lathe: High-precision turning of cylindrical and tapered surfaces, thread cutting, grooving.

- 5-Axis Machining Center: Multi-directional milling of complex contours, slots, pockets, and undercuts.

- Boring Machine: Precise enlargement and finishing of holes (e.g., coolant channels, mounting bores).

- Drilling Machine (CNC or Manual): Drilling holes for coolant passages and assembly features.

- Vibratory Finishing Machine: Batch processing with media and slurry for small parts.

- Polishing Wheel/Bench Polisher: Point-specific polishing on complex geometries and seal rings.

- Ultrasonic Cleaning + Polishing Systems: Integrated cleaning to remove residues before and after polishing.

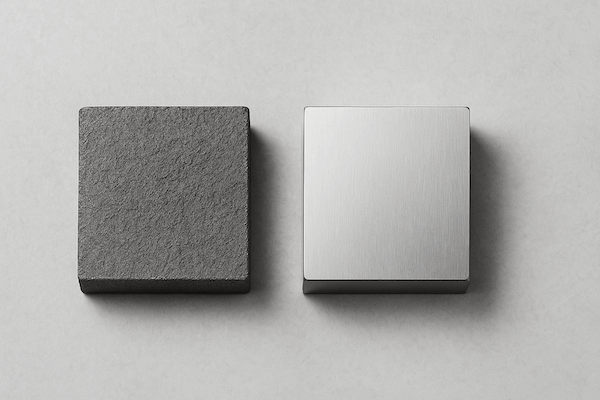

Introduction: The Critical Role of Surface Integrity

Tungsten carbide tools must endure extreme pressures, temperatures, and abrasion. Achieving the right geometry, dimension, and surface finish is essential for tool life and cutting performance. Grinding shapes the raw sintered part, machining adds complex features, and polishing removes micro-defects—together ensuring wear resistance, fatigue strength, and consistent results in your applications.

Advanced Grinding: Precision Geometry & Burr Removal

We employ OD/ID cylindrical grinders, surface grinders, and CNC tool grinders with diamond abrasives. Coarse grinding (#80–#120 grit) removes bulk material; fine grinding (#240–#400 grit) defines edges and flats to ±0.005 mm. Our centerless grinders handle bar stock efficiently, while CNC tool grinders contour complex chip-breaker and chamfer geometries without thermal damage.

Precision Machining: Complex Features & High Throughput

On our CNC lathes and 5-axis milling centers, we rough and semi-finish carbide tools using PVD-coated, diamond-tipped cutters. Cutting speeds up to 300 m/min and feeds of 0.1 mm/tooth enable efficient slotting, pocketing, and hole creation. Boring and drilling machines produce coolant channels and mounting bores with tolerances of ±0.01 mm, ready for final finishing.

Quick and easy: Enter your specifications and get a quote in one business day

High-Fidelity Polishing: Mirror-Like Surface & Micro-Crack Removal

Our polishing stations and vibratory finishers use diamond paste (0.25–3 µm) and alumina slurry (0.05–1 µm) to achieve Ra ≤ 0.05 µm on sealing faces and high-gloss edges. Ultrasonic cleaning precedes polishing to strip recast layers. The result: pristine surfaces that minimize friction, prevent built-up edge, and maximize corrosion resistance.

Integrated Process Flow: Seamless Transitions

Our in-house workflow tightly integrates grinding, machining, and polishing. After sintering, parts move directly to grinding for geometry, then to CNC machines for features, and finally to polishing stations. This one-stop process reduces handling, shortens lead times, and maintains traceability—every step recorded in our digital MES system.

Rigorous Quality Control at Every Step

We verify dimensions with CMM (±0.005 mm), surface roughness with profilometers (Ra ≤ 0.05 µm), and microstructure via metallography. Hardness testers confirm binder distribution, while optical comparators inspect chamfers and fillets. Our ISO-certified QA lab ensures each tool meets customer specs before shipment.

Conclusion

Our seasoned team of grinding, machining, and polishing specialists delivers custom geometries, rapid prototyping, and volume runs. With 24/7 technical support and process optimization services, we ensure your carbide tools perform flawlessly in automotive, aerospace, oil & gas, and more. Trust our mature capabilities for your most demanding applications.

By harnessing state-of-the-art equipment, deep process knowledge, and stringent QC, we guarantee tungsten carbide tools with exceptional precision, durability, and surface integrity. Partner with us to elevate your machining performance.

Quick and easy: Enter your specifications and get a quote in one business day