Introduction

When choosing cutting tools for CNC machining and manufacturing, two common options are tungsten carbide and high-speed steel (HSS). Both tools have their benefits and are used in many industries.

This simple guide will help you understand the differences between tungsten carbide and high-speed steel, helping you choose the right tool for your application.

What Is Tungsten Carbide?

Tungsten carbide is a material made by combining tungsten and carbon with a metal binder, usually cobalt. It is extremely hard and can cut tough materials easily.

Key features of tungsten carbide:

✅ Very hard and wear-resistant

✅ Can cut at high speeds

✅ Works well on hard materials like stainless steel and titanium

✅ Stays sharp for a long time

You can learn more about tungsten carbide in our Tungsten Carbide Technical Glossary.

What Is High-Speed Steel (HSS)?

High-speed steel is a type of tool steel with high hardness and heat resistance. It is made from steel mixed with elements like tungsten, molybdenum, and chromium.

Key features of HSS:

✅ Tough and can handle impact well

✅ Less expensive than tungsten carbide

✅ Easier to sharpen

✅ Works well for low to medium cutting speeds

Hardness and Wear Resistance

Tungsten carbide is much harder than HSS. This means it can keep its cutting edge for a longer time and can handle high-speed cutting without wearing out quickly.

HSS is tough and can handle shocks and vibrations during cutting, but it wears out faster than tungsten carbide when cutting hard materials.

✅ Winner: Tungsten carbide for hardness and wear resistance.

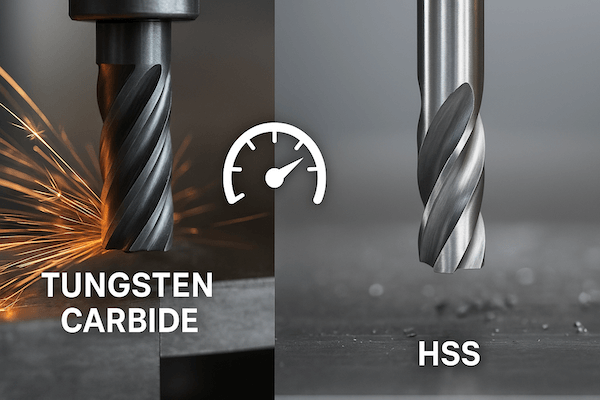

Cutting Speed

Tungsten carbide tools can operate at much higher cutting speeds than HSS tools. This means you can produce more parts in less time, which increases productivity in your workshop.

HSS tools work best at lower cutting speeds to prevent overheating and wear.

✅ Winner: Tungsten carbide for high-speed cutting.

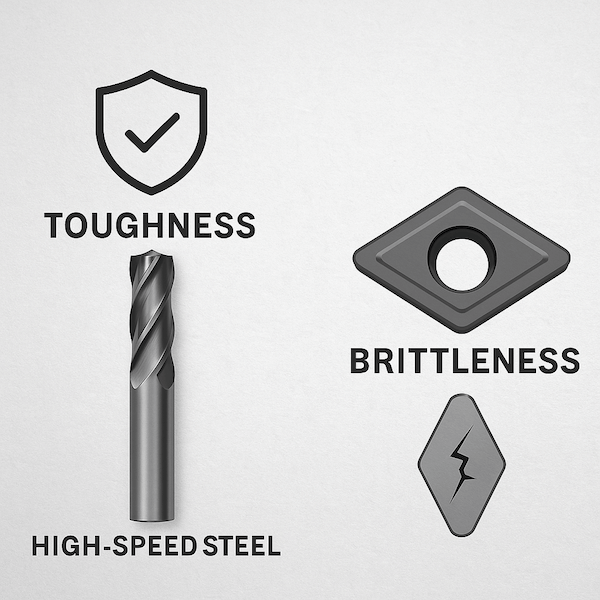

Toughness

Toughness is the ability to handle shocks and vibrations without breaking. HSS is tougher than tungsten carbide, making it a good choice for cutting operations where vibration or interrupted cuts are common.

Tungsten carbide is harder but more brittle and can chip if used in heavy shock applications.

✅ Winner: HSS for toughness.

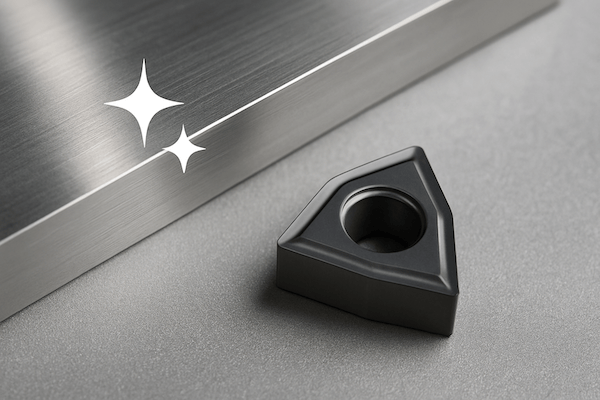

Surface Finish

Tungsten carbide tools maintain a sharper edge, which helps achieve a smoother surface finish on your workpiece. This reduces the need for additional finishing processes.

HSS can also provide a good surface finish but may lose sharpness faster, especially on hard materials.

✅ Winner: Tungsten carbide for surface finish on hard materials.

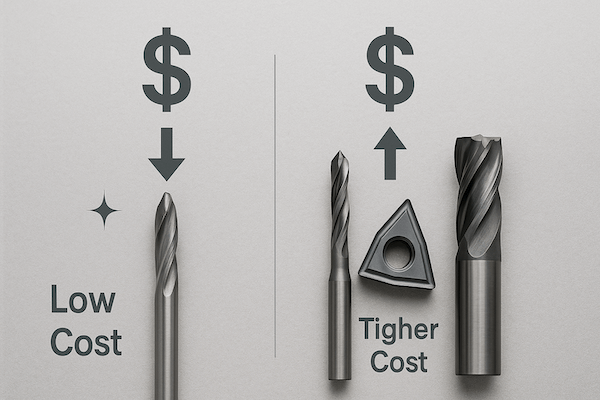

Cost

HSS tools are cheaper than tungsten carbide tools, making them a good choice for small workshops with tight budgets or low-volume jobs.

While tungsten carbide tools are more expensive upfront, they last longer and reduce tool change downtime, making them cost-effective in the long run.

✅ Winner: HSS for low upfront cost, tungsten carbide for long-term value.

Applications

Tungsten carbide tools are used in:

High-speed CNC machining

Cutting hard materials (steel, titanium, cast iron)

Production environments where high volume is needed

Applications requiring tight tolerances

HSS tools are used in:

Low to medium-speed cutting

Applications with vibration or interrupted cuts

Small batch production

Cutting softer materials like aluminum and mild steel

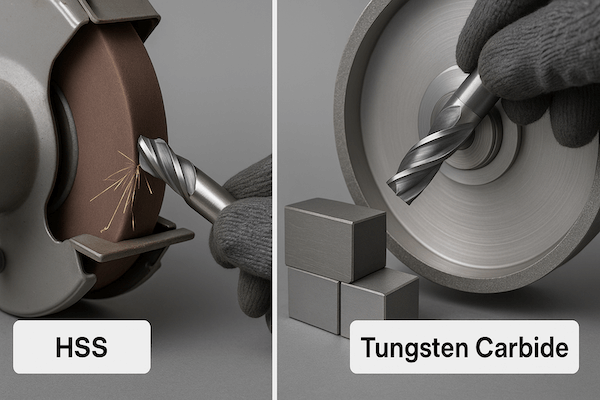

Maintenance and Sharpening

HSS tools are easier to sharpen using standard grinding equipment, making them easy to maintain.

Tungsten carbide tools require diamond grinding wheels for sharpening, which may not be available in all workshops.

✅ Winner: HSS for ease of sharpening.

Summary Table: Tungsten Carbide vs High-Speed Steel

| Feature | Tungsten Carbide | High-Speed Steel |

|---|---|---|

| Hardness | Very High | Medium |

| Toughness | Low | High |

| Cutting Speed | High | Low to Medium |

| Wear Resistance | Excellent | Good (but lower) |

| Surface Finish | Excellent | Good |

| Cost | High (long-term value) | Low (budget-friendly) |

| Sharpening | Requires diamond wheels | Easy to sharpen |

Which Cutting Tool Should You Choose?

✅ Choose Tungsten Carbide If:

You need high cutting speeds

You work with hard materials

You want a longer tool life

You need high-quality surface finishes

✅ Choose High-Speed Steel If:

You need a budget-friendly option

Your machining involves vibration or interrupted cuts

You work with soft materials

You need easy sharpening and maintenance

Why Choose Retop for Tungsten Carbide Cutting Tools?

Retop is a trusted supplier of high-quality tungsten carbide cutting tools designed to help your business improve productivity and reduce costs.

✅ Over 14 years of manufacturing experience

✅ ISO-certified quality control

✅ Custom solutions for your machining needs

✅ Global shipping and fast delivery

To explore our full range of tungsten carbide tools, visit our Tungsten Carbide Cutting Tools page.

Conclusion

Both tungsten carbide and high-speed steel have their advantages. Your choice should depend on your specific needs, such as:

✅ The material you are cutting

✅ The cutting speed you require

✅ Your budget and production volume

✅ The level of precision and surface finish needed

Using the right cutting tool helps improve your machining efficiency, save costs, and deliver better results to your customers.