Tungsten carbide cutting tools are widely used in manufacturing, metalworking, and construction industries because they are strong, durable, and efficient. But how do these tools affect the environment? In this article, we will explore both the positive and negative environmental impacts of using tungsten carbide cutting tools and offer suggestions for more sustainable usage.

What Is Tungsten Carbide?

Tungsten carbide is a very hard material made by combining tungsten and carbon. It is used to make cutting tools because it lasts much longer than steel tools and can cut very hard materials.

Tungsten carbide cutting tools are commonly used in industries that need high-speed cutting, precise machining, or wear resistance. These tools are often used to make parts in the automotive, aerospace, medical, and electronics industries.

You can learn more about different tungsten carbide tools on www.retopz.com. Visit our product pages for detailed specifications and applications.

Positive Environmental Impacts

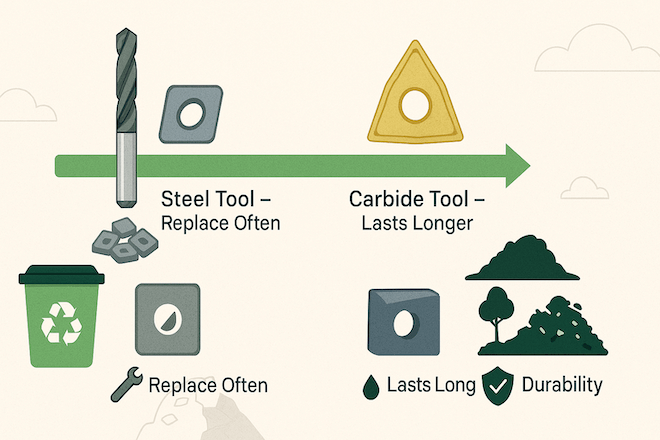

1. Longer Tool Life = Less Waste

One of the biggest advantages of tungsten carbide tools is their long lifespan. Compared to steel tools, they need to be replaced less often. This means:

Less production waste

Fewer tools end up in landfills

Reduced need for frequent shipments

By choosing high-quality carbide tools, companies can reduce the number of tools they throw away, helping the environment.

2. Greater Efficiency Reduces Energy Use

Tungsten carbide tools are sharper and stronger than other tools. Because of this, they can cut materials faster and more accurately. This leads to:

Shorter machine run-time

Less electricity used

Lower carbon emissions

This benefit is especially important in mass production and high-speed machining operations.

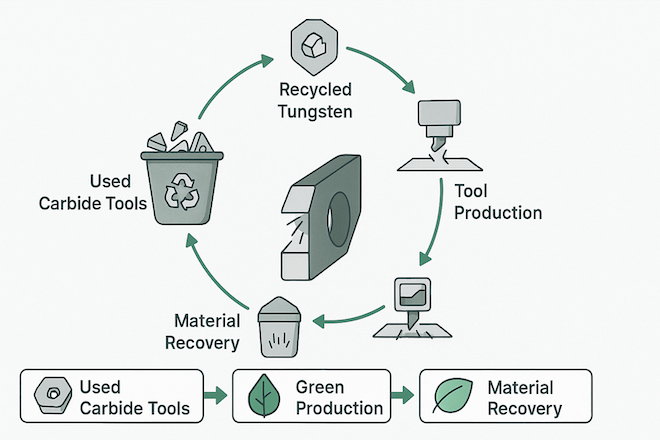

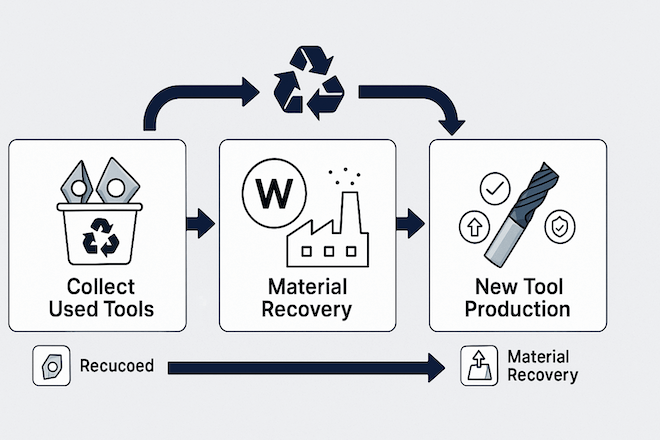

3. Recycling and Reuse Potential

Used tungsten carbide tools can be recycled. The tungsten and cobalt inside can be extracted and reused to make new tools. This reduces the need for mining raw materials.

Recycling carbide tools can:

Save natural resources

Lower pollution from mining

Cut down on production energy

At Retop, we support carbide tool recycling and encourage our clients to return worn-out tools.

Negative Environmental Impacts

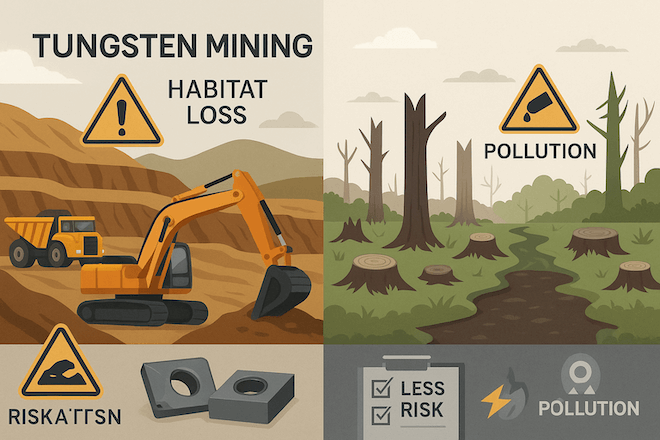

1. Mining and Raw Material Extraction

Tungsten is a rare metal. Mining tungsten can have a serious environmental impact, including:

Deforestation

Water pollution

Habitat destruction

These effects occur in countries where tungsten is mined, such as China, Russia, and Bolivia.

2. High Energy Use in Manufacturing

Making tungsten carbide tools involves high sintering temperatures and pressurized equipment. These processes require:

A lot of energy

High CO₂ emissions

Even though the tools last longer, the energy used in production is high compared to tools made from steel or aluminum.

3. Waste If Not Recycled

If old carbide tools are not recycled, they are often sent to landfills or burned, which wastes valuable metals and pollutes the environment.

How to Make Tungsten Carbide Tools More Eco-Friendly

To reduce the environmental impact, manufacturers and users should focus on sustainable practices. Here are some tips:

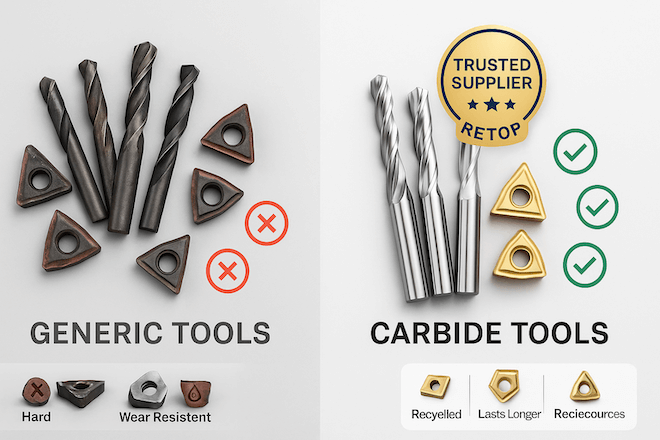

Choose Quality Tools

High-quality tools perform better and last longer. Buying from trusted suppliers like Retop ensures:

Better tool life

Less frequent replacement

More sustainable use

Regrind and Reuse

Carbide tools can often be resharpened instead of thrown away. This process is called regrinding. It can:

Extend tool life by up to 50–70%

Reduce the number of new tools needed

Save money and materials

Retop provides regrinding services to help our customers reuse their carbide tools.

Recycle Used Tools

Work with recycling programs that accept used carbide tools. Many companies collect worn-out tools and recover the valuable tungsten inside.

Some benefits of carbide recycling:

Prevents metal waste

Reduces the need for mining

Lowers overall emissions

Comparing Environmental Impact: Carbide vs. Steel Tools

| Feature | Carbide Tools | Steel Tools |

|---|---|---|

| Tool Life | Very long | Short |

| Cutting Efficiency | High | Medium |

| Production Energy Use | High | Low |

| Waste Generation | Low (if recycled) | High |

| Recyclability | Yes | Yes |

| Environmental Impact | Balanced (if reused) | Higher waste & replacement |

Final Thoughts

Tungsten carbide cutting tools offer many environmental benefits when used and recycled correctly. While the manufacturing process requires more energy, the longer tool life, recycling potential, and cutting efficiency make them a better choice for sustainable production in the long run.

To make the most eco-friendly choice:

Buy from trusted suppliers like Retop

Choose regrindable and recyclable carbide tools

Follow proper maintenance and recycling methods

For reliable and sustainable tooling solutions, explore our full range at www.retopz.com. We are committed to delivering high-performance tools with environmental responsibility.