Introduction

In the automotive industry, precision, speed, and efficiency are key to success. Manufacturers need to produce thousands of parts every day while maintaining tight tolerances and consistent quality. This is where tungsten carbide cutting tools play an important role.

This article explores how tungsten carbide tools are used in automotive part production, what benefits they bring, and why they are a smart choice for automotive companies that want to stay competitive.

Why Automotive Manufacturing Needs High-Performance Cutting Tools

Producing automotive parts is a complex and demanding process. Companies must deal with:

Hard materials like steel, cast iron, and aluminum alloys

High production volumes with minimal downtime

Complex shapes that require accurate machining

Tight tolerances for performance and safety

Cost pressure from global competition

To meet these challenges, advanced cutting tools are needed—tools that can perform consistently and reliably under heavy loads and high speeds.

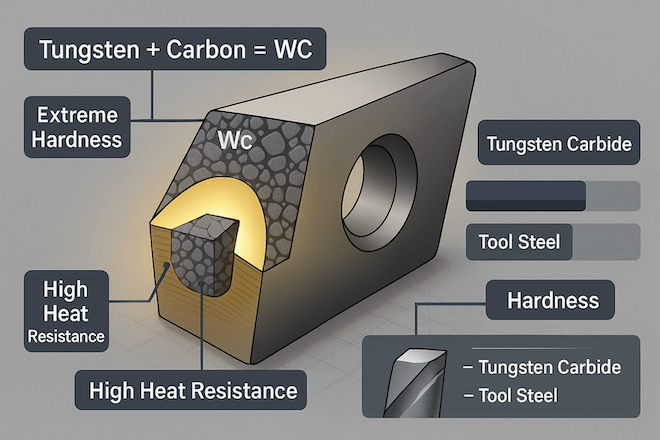

What Is Tungsten Carbide?

Tungsten carbide is a very hard material made by combining tungsten (W) and carbon (C). It is:

Harder than most metals

More heat-resistant

Very wear-resistant

Stronger than steel

These features make it ideal for cutting tools used in automotive machining.

Tungsten carbide cutting tools include drills, inserts, reamers, end mills, and custom tools used in CNC machines to cut, shape, and finish metal parts with high precision.

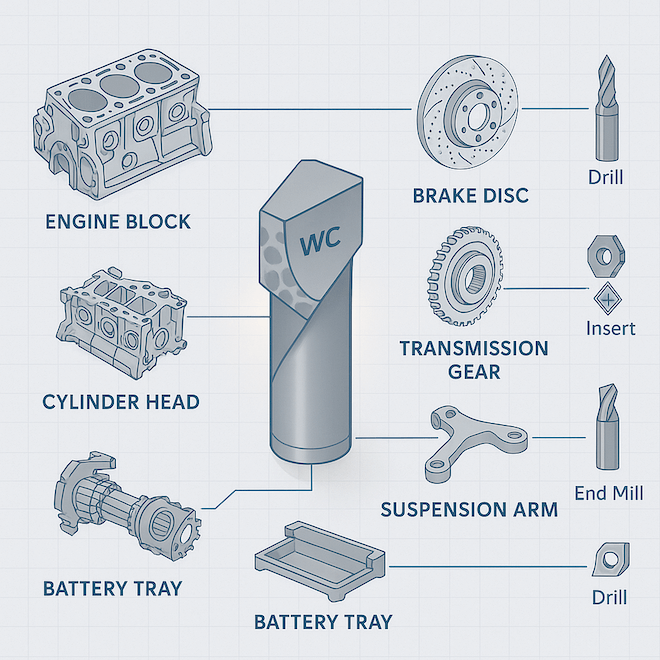

Common Automotive Parts Machined with Tungsten Carbide Tools

Carbide tools are used across many stages of vehicle manufacturing, including:

| Part Category | Typical Components | Carbide Tool Used |

|---|---|---|

| Engine Components | Cylinder heads, engine blocks, pistons | Carbide drills, reamers, end mills |

| Transmission Systems | Gears, shafts, housings | Carbide inserts, chamfer tools |

| Braking Systems | Brake pads, discs, calipers | Carbide cutting inserts |

| Suspension & Steering | Control arms, steering knuckles | Carbide tools for milling & drilling |

| Fuel & Exhaust Systems | Injection nozzles, exhaust manifolds | Micro carbide tools |

| Electric Vehicle Parts | Battery trays, motor housings | Custom carbide cutters |

Key Benefits of Tungsten Carbide Tools in Automotive Production

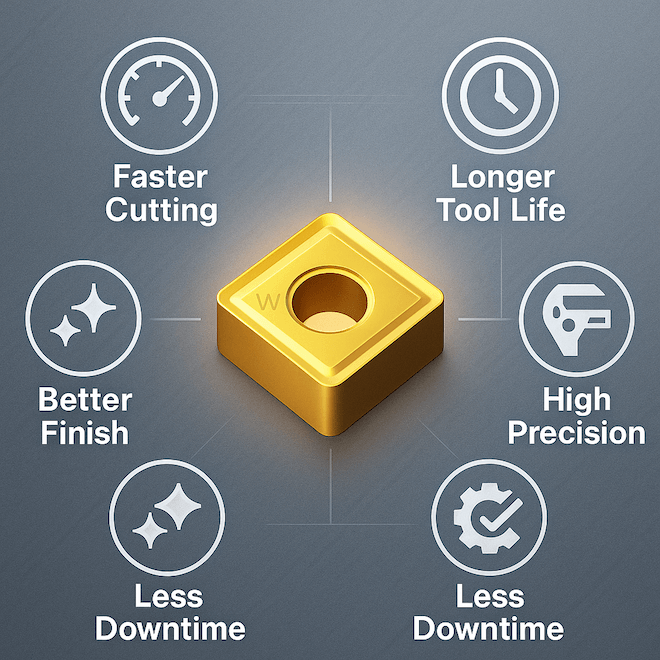

1. Long Tool Life

Tungsten carbide tools resist wear and heat, which allows them to last much longer than regular tools. This leads to:

Fewer tool changes

Less machine downtime

Lower tool cost per part

This is especially valuable in mass production environments.

2. High-Speed Cutting

Carbide tools can operate at higher cutting speeds, increasing productivity. They allow:

Faster cycle times

Greater output per shift

Improved machine efficiency

This helps manufacturers meet delivery deadlines and reduce backlog.

3. Better Surface Finish and Tolerance Control

Automotive parts need precise finishes to meet safety and performance requirements. Carbide tools deliver:

Clean cuts

Smooth surfaces

Accurate dimensions

This reduces the need for rework and ensures high-quality parts.

4. Performance on Difficult Materials

Modern cars use harder and lighter materials for fuel efficiency and safety. Tungsten carbide tools perform well on:

Hardened steel

Cast iron

Aluminum alloy

Powder metallurgy parts

They can also handle coated or treated surfaces like nitrided or chrome-plated parts.

5. Consistency in Large Volumes

In automotive production, the ability to make identical parts over long production runs is critical. Carbide tools offer repeatable performance that reduces variation.

This supports lean manufacturing goals and keeps quality audits clean.

Why Automotive Decision Makers Choose Tungsten Carbide

As a leader in automotive manufacturing, your focus is on:

Reducing cycle time

Lowering per-part costs

Ensuring part quality and safety

Improving sustainability

Tungsten carbide cutting tools help meet all these goals. They also support automation and CNC integration, which are key in modern smart factories.

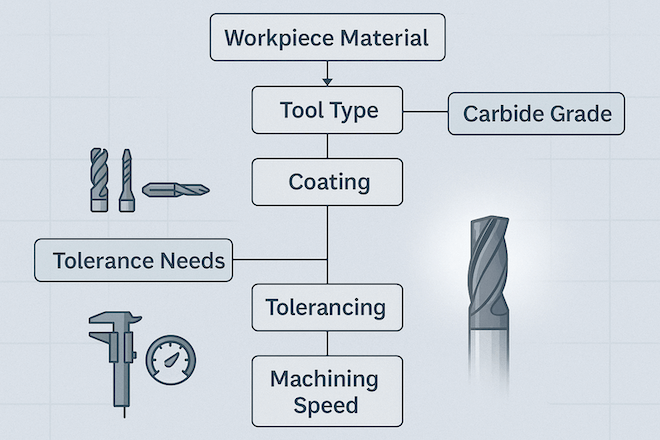

How to Choose the Right Carbide Tool for Automotive Applications

Here are a few tips to get the best results:

Match the tool to the material: Use the right carbide grade for steel, cast iron, or aluminum.

Use coated tools: TiAlN, DLC, or diamond coatings improve tool life and reduce heat.

Choose correct tool geometry: For example, chip breakers and flute design for different parts.

Monitor wear: Use sensors or regular checks to avoid tool failure.

Work with experienced suppliers: Custom tools can make a big difference in productivity.

Working with a Reliable Partner Like Retop

At Retop, we have over 14 years of experience in producing tungsten carbide cutting tools for the automotive industry. Our products are:

Made with high-grade carbide

Customizable for specific parts

Coated for improved performance

Tested for precision and consistency

👉 Visit www.retopz.com to learn more about our tools for engine, transmission, braking, and EV component production.

We work with top-tier automotive suppliers across the world to help them improve tool efficiency and reduce manufacturing costs.

Conclusion

In today’s competitive automotive market, success depends on quality, speed, and cost control. Tungsten carbide cutting tools offer the perfect combination of performance and durability to meet these needs.

From engine blocks to battery components, carbide tools help you deliver reliable, precise parts every time. If you want to improve your production process, reduce downtime, and stay ahead in the automotive industry, it’s time to invest in high-quality carbide tools from a trusted partner like Retop.