Introduction

Mold and die manufacturing is a critical part of modern industry. From making plastic parts to shaping metal products, this process requires high precision and durable tools. One material that has become a favorite for toolmakers is tungsten carbide. This article explains how tungsten carbide cutting tools help improve productivity, accuracy, and cost-efficiency in mold and die manufacturing.

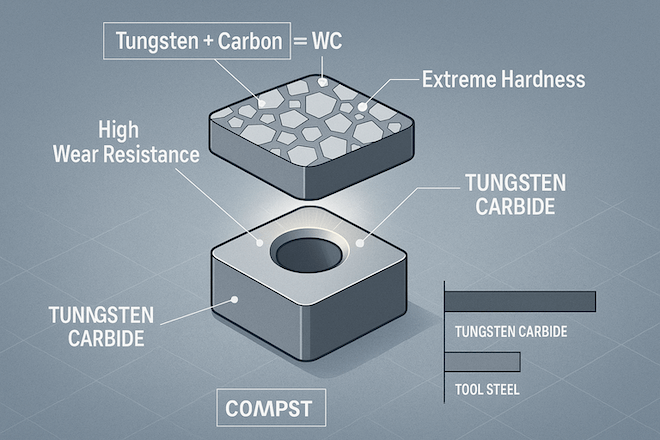

What Is Tungsten Carbide?

Tungsten carbide is a composite material made of tungsten and carbon, often bonded with cobalt. It is known for:

Extreme hardness

High wear resistance

Excellent heat resistance

Compared to standard tool steels, tungsten carbide tools last much longer and perform better under high-pressure and high-temperature conditions.

Why Tungsten Carbide Tools Are Ideal for Mold and Die Making

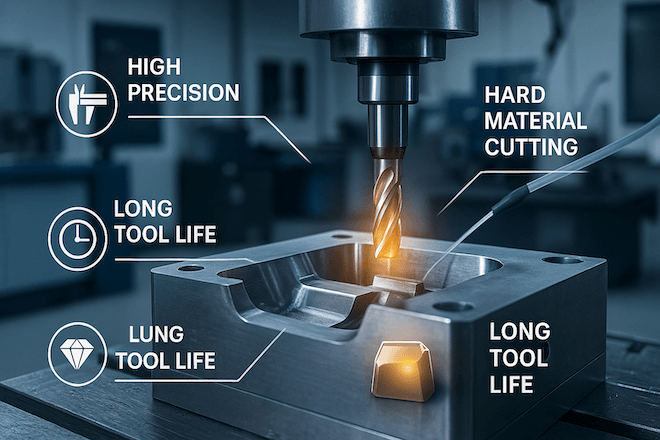

1. Handles Hard Materials

In mold and die manufacturing, materials like hardened steel, graphite, and alloyed metals are common. These materials are difficult to cut. Tungsten carbide tools are strong enough to machine them without quick wear.

2. High Dimensional Accuracy

Molds and dies must have exact shapes and tight tolerances. Carbide tools maintain sharp edges and consistent performance, which ensures precise cutting.

3. Better Surface Finish

Carbide tools can provide smooth surfaces even in difficult materials, reducing the need for polishing or secondary operations.

4. Long Tool Life

Because of their hardness and heat resistance, tungsten carbide cutting tools last longer. This reduces the need for frequent replacements.

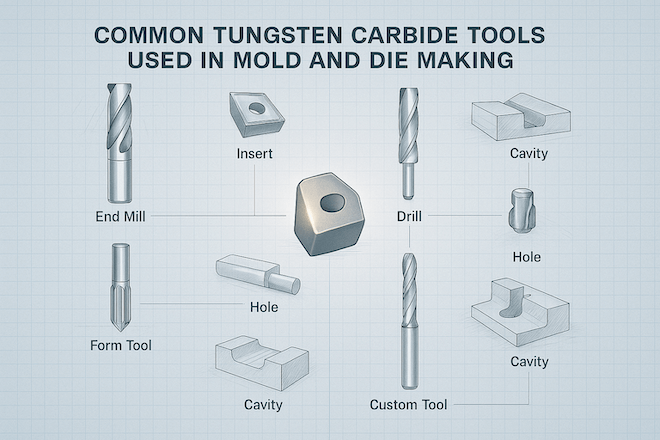

Common Tungsten Carbide Tools Used in Mold and Die Making

Here are some popular carbide tools used in this field:

| Tool Type | Usage |

|---|---|

| Carbide End Mills | Used for contouring, slotting, and roughing |

| Carbide Inserts | Common in CNC lathes for turning dies |

| Carbide Reamers | For finishing holes in mold plates |

| Carbide Drills | Drilling holes in hard steel or graphite dies |

| Form Tools | Custom-shaped tools for unique mold profiles |

You can explore our full collection of precision tools at Retop’s carbide cutting tool section.

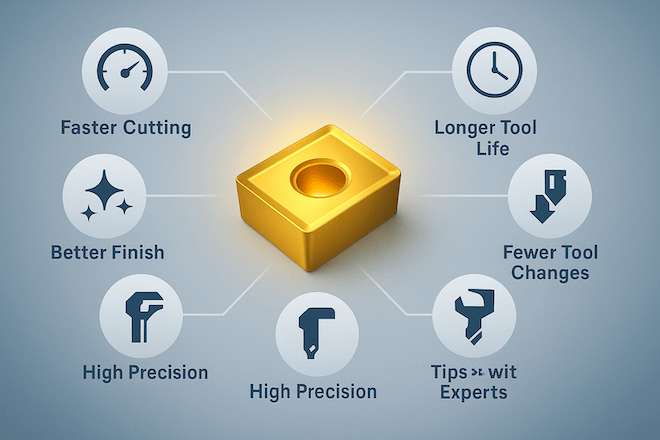

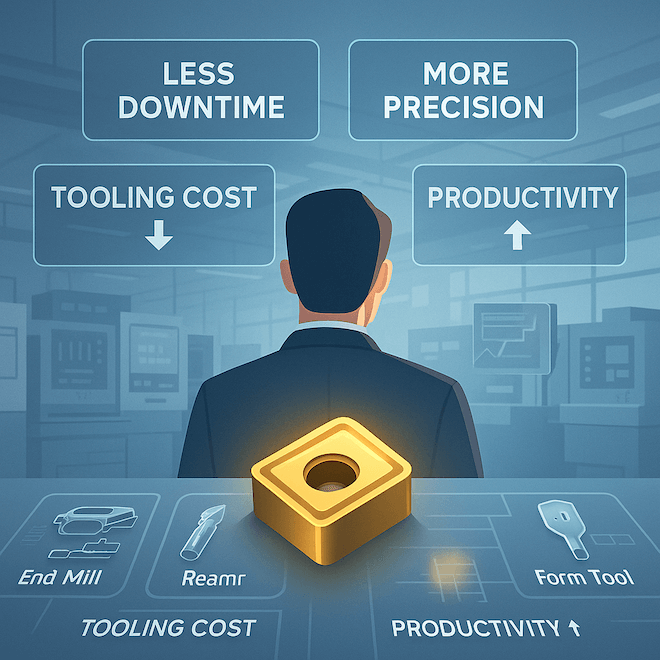

Benefits of Using Tungsten Carbide Cutting Tools

Less Tool Change Time: Longer tool life means fewer machine stoppages.

Lower Production Costs: Higher cutting speed and durability reduce the cost per part.

Improved Efficiency: Carbide tools can cut faster and cleaner, boosting output.

Reliable Performance: Consistent quality, especially important in multi-cavity molds or high-volume dies.

Precision: Perfect for industries that require tight tolerances, such as automotive and electronics.

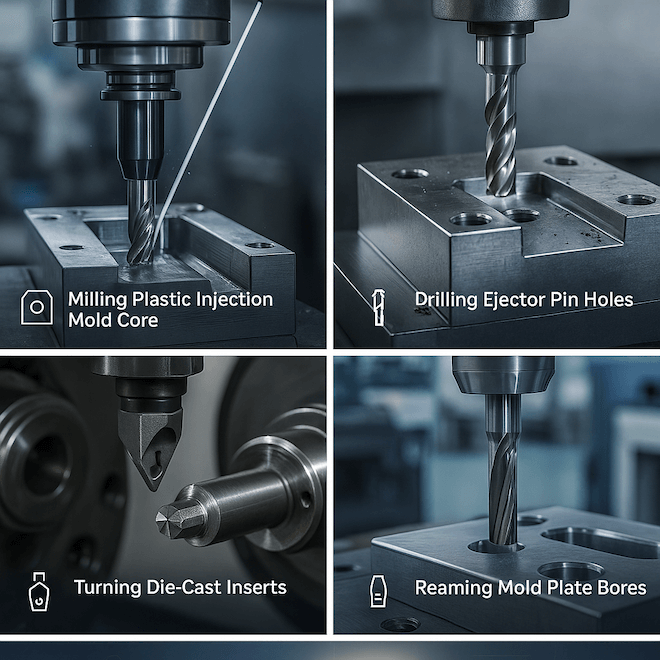

Applications in Mold and Die Industry

Tungsten carbide tools are used in several mold and die processes:

Injection Mold Making: Carbide tools are used to mill core and cavity areas.

Die Casting: For high-wear areas in dies, like gates and runners.

Punch and Die Sets: Carbide inserts are used in progressive dies for sheet metal.

Plastic Mold Components: Carbide reamers and drills provide tight-fitting parts.

Why Decision Makers Choose Tungsten Carbide

Executives and managers in mold and die shops value:

Consistency in output

Lower tooling costs over time

Fewer production delays

High-quality parts that meet customer demands

Tungsten carbide cutting tools deliver all these benefits, making them a smart investment for companies looking to stay competitive.

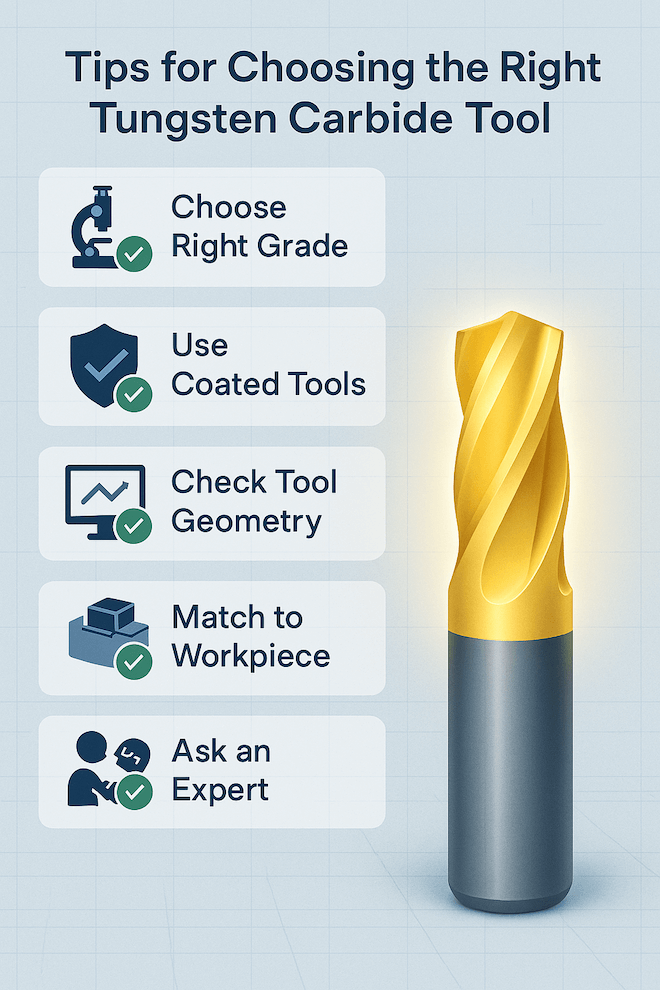

Tips for Choosing the Right Tungsten Carbide Tool

Here’s how to make the best choice:

Know Your Material: Choose the right carbide grade for steel, aluminum, or graphite.

Pick the Right Coating: TiAlN or AlCrN coatings can improve tool life.

Use the Right Tool Geometry: Tool shape matters for surface finish and chip flow.

Consult Experts: Working with trusted suppliers like Retop helps ensure better tool performance and support.

Conclusion

Tungsten carbide cutting tools are a game-changer in the mold and die industry. They offer better performance, lower downtime, and higher accuracy. For companies that want to increase productivity while maintaining quality, switching to carbide is the smart move.