In industries like oil & gas, chemical processing, mining, and power generation, pumps, valves, and seals face extreme conditions.

They often operate under high pressure, with abrasive particles, and in corrosive fluids. This constant exposure leads to rapid wear and costly downtime. One solution trusted worldwide is tungsten carbide.

Known for its hardness, wear resistance, and durability, tungsten carbide protects critical components, helping companies reduce maintenance costs and extend equipment life.

This article explains how tungsten carbide is used in pump, valve, and seal wear protection, the benefits it offers, and the key considerations for choosing the right grade.

Why Pumps, Valves, and Seals Need Wear Protection

Pumps, valves, and seals are exposed to:

Abrasive solids in liquids

High pressure and velocity

Corrosive chemicals

Temperature fluctuations

Without wear protection, these conditions can:

Damage sealing surfaces

Cause leakage and system failure

Increase unplanned downtime

Raise repair and replacement costs

Tungsten carbide combats these challenges by creating a tough, hard barrier against wear, erosion, and corrosion.

Properties That Make Tungsten Carbide Ideal

| Property | Benefit in Pumps, Valves, and Seals |

|---|---|

| High Hardness | Resists abrasion from sand, slurry, and particulates |

| High Compressive Strength | Handles extreme operating pressures |

| Wear Resistance | Extends lifespan of contact surfaces |

| Corrosion Resistance | Suitable for aggressive chemicals and saltwater |

| Thermal Stability | Performs well in high-temperature applications |

These properties allow tungsten carbide to outperform traditional steel and other alloys in heavy-duty industrial applications.

Applications in Pumps

Pump Shafts and Sleeves

Tungsten carbide coatings or sleeves protect shafts from wear caused by seals and abrasive fluids.

Pump Bearings

Carbide bearings maintain performance even in slurry-handling pumps, where abrasive particles can destroy softer metals.

Mechanical Seal Faces

In pumps handling chemicals or seawater, tungsten carbide faces provide a smooth, hard surface that maintains seal integrity.

Applications in Valves

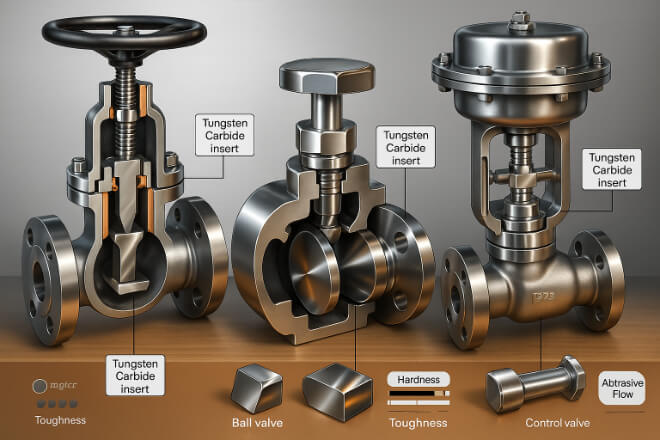

Gate Valves

The sealing edges of gate valves can be lined with tungsten carbide to resist wear from abrasive flow.

Ball Valves

Carbide-coated balls and seats reduce wear and prevent leakage in high-pressure systems.

Control Valves

For precise flow regulation in erosive conditions, tungsten carbide trim ensures long-term accuracy.

Applications in Seals

Mechanical Seals

Tungsten carbide is a standard material for one or both sealing faces, especially in slurry pumps and mixers.

Rotary Seals

In rotating equipment, carbide resists friction and wear at the sealing interface.

Static Seals

Carbide coatings prevent damage from particles trapped at sealing surfaces.

Choosing the Right Tungsten Carbide Grade

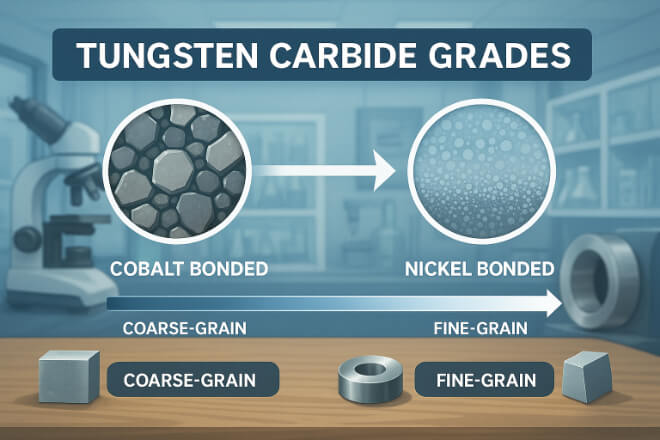

Not all tungsten carbide is the same. The grade depends on:

Binder content (usually cobalt or nickel) – affects toughness and corrosion resistance.

Grain size – fine grain offers higher wear resistance; coarse grain provides more toughness.

Coating type – may be applied by HVOF (high-velocity oxygen fuel) spraying or other thermal spray methods.

For example:

Cobalt-bonded tungsten carbide: Best for general wear and impact resistance.

Nickel-bonded tungsten carbide: Better in corrosive environments.

Benefits for Industrial Decision-Makers

| Benefit | Business Impact |

|---|---|

| Longer equipment life | Lower replacement costs |

| Reduced downtime | Higher productivity |

| Better performance in harsh media | Reliability in critical operations |

| Lower maintenance | Reduced labor and spare parts cost |

Investing in tungsten carbide wear protection is not just about component life — it’s about protecting overall system efficiency and profitability.

Maintenance and Inspection Tips

Regular inspections detect wear before it becomes critical.

Proper installation ensures even load distribution on carbide parts.

Choose the right grade for the specific fluid and operating conditions.

Partner with a trusted supplier to ensure consistent quality.

Conclusion

For pumps, valves, and seals working in demanding industrial environments, tungsten carbide is one of the best materials for wear protection.

Its hardness, wear resistance, and corrosion resistance make it a valuable investment for companies that want to minimize downtime and maximize reliability.

Whether in oil & gas, chemical processing, or mining, upgrading to tungsten carbide components can significantly improve operational efficiency and cost savings.

If you want to know more details about any company, please feel free to contact us.