Tungsten carbide wear parts are used in industries where tools face heavy wear, heat, or impact. But not all tungsten carbide is the same.

Different grades are made to handle different working conditions. Choosing the wrong grade can cause early failure, higher costs, and downtime. Choosing the right grade ensures maximum tool life and performance.

In this guide, we explain what grades mean, how they differ, and how to select the right one for your application.

The goal is to make this process simple and clear, especially for decision-makers in manufacturing, mining, oil & gas, metal forming, and other heavy industries.

Understanding Tungsten Carbide Grades

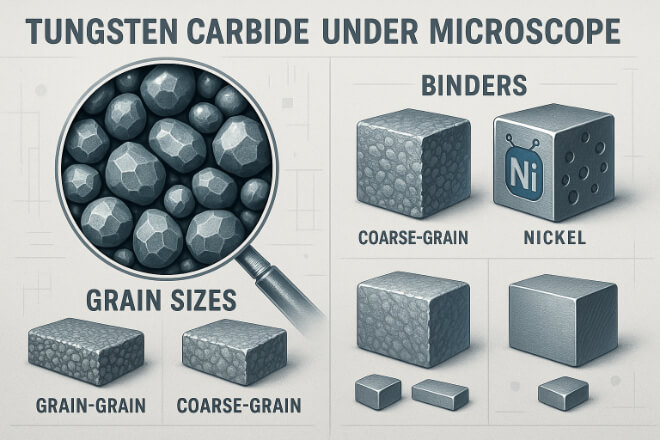

A tungsten carbide grade is a mix of two main things:

Grain size of the carbide particles

Binder type and percentage (usually cobalt or nickel)

Different mixes change the hardness, toughness, and wear resistance of the part.

The Hardness–Toughness Balance

Hardness means resistance to wear, while toughness means resistance to breaking or chipping.

Higher hardness → better wear resistance, but less impact resistance.

Higher toughness → better impact resistance, but slightly less wear resistance.

This is why a mining drill bit and a precision cutting die use very different grades.

Common Tungsten Carbide Grades and Their Uses

| Grade Type | Main Properties | Best For |

|---|---|---|

| Fine-Grain Carbide | High hardness, excellent wear resistance | Precision cutting tools, dies, wear-resistant nozzles |

| Coarse-Grain Carbide | Higher toughness, impact resistance | Mining tools, drilling bits, heavy-duty wear parts |

| Submicron Carbide | Extreme hardness, smooth finish | Medical tools, fine machining, precision parts |

| Nickel-Bonded Carbide | Corrosion resistance | Oil & gas valves, chemical pumps, marine applications |

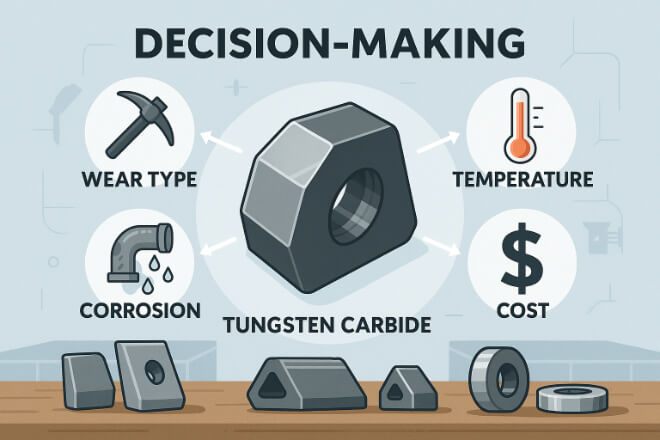

Factors to Consider When Choosing a Grade

When selecting a tungsten carbide grade, decision-makers should look at:

Type of Wear – Is it abrasive wear, impact wear, or a mix?

Operating Temperature – Some binders perform better at high heat.

Corrosion Risk – If the part is in a chemical or wet environment, nickel-bonded grades help.

Cost vs. Performance – A higher grade may cost more but can last much longer.

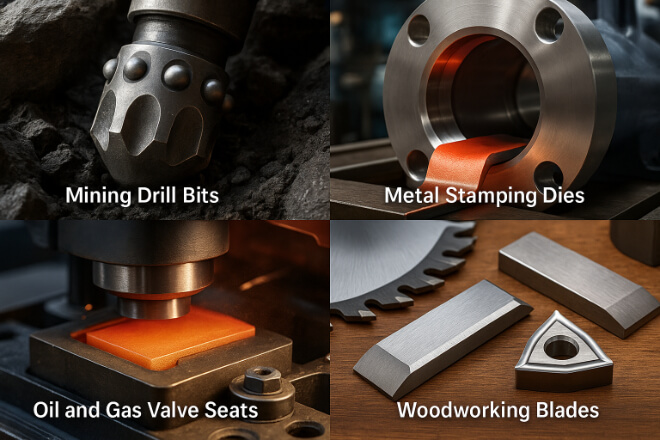

Industry Examples

Mining: Coarse-grain carbide for impact resistance in drilling and crushing.

Metal Forming: Fine-grain carbide for dies and punches to handle abrasion.

Oil & Gas: Nickel-bonded carbide for valve seats exposed to corrosive fluids.

Woodworking: Medium-grain carbide for balance between sharpness and strength.

Tips for Decision-Makers

Work with a supplier who can test samples for your specific job.

Track wear patterns on existing tools to understand what’s failing first.

Avoid over-specifying — a more expensive grade may not always improve performance.

Conclusion

Choosing the right tungsten carbide grade is a balance of hardness, toughness, and environmental needs.

By understanding how grades work, decision-makers can extend tool life, reduce downtime, and improve efficiency. The right choice saves money and increases reliability over the long term.

If you want to know more details about any company, please feel free to contact us.