Tungsten carbide is one of the most common materials used for cutting tools, wear parts, and industrial components.

It is valued for its hardness, wear resistance, and ability to keep performance under heat.

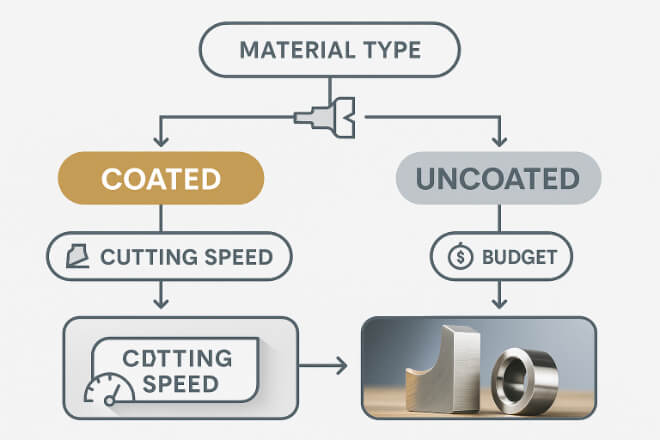

However, not all tungsten carbide parts are the same. Some are coated, and others are uncoated. The coating can change how the part behaves, how long it lasts, and how it performs in different environments.

For decision-makers in manufacturing, mining, oil and gas, and precision machining, choosing between coated and uncoated tungsten carbide is a strategic decision that can impact productivity and cost.

This article compares the two options so you can make the best choice for your needs.

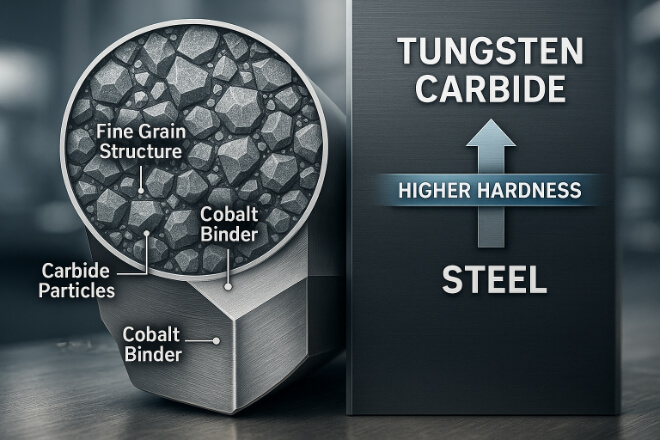

What Is Tungsten Carbide?

Tungsten carbide is a compound made from tungsten (W) and carbon (C). The result is a very hard material — harder than steel and close to diamond on the hardness scale.

It is often used in:

Cutting tools (end mills, drills, inserts)

Mining tools

Pump and valve components

Wear-resistant dies and nozzles

The strength and wear resistance come from its fine grain structure and high density.

But without a coating, even tungsten carbide can wear faster in certain environments.

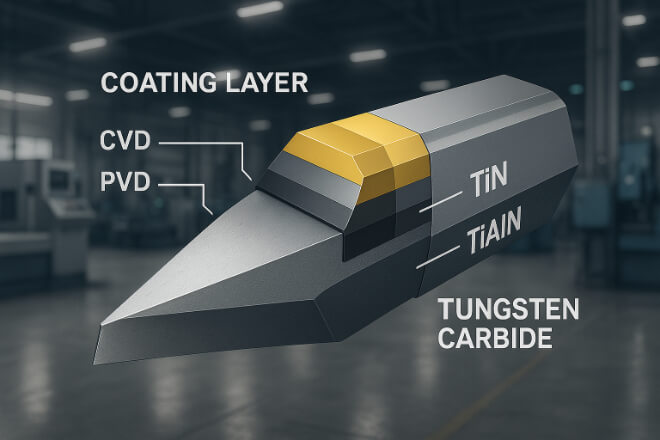

What Does “Coated” Tungsten Carbide Mean?

Coated tungsten carbide has a thin layer of another material on its surface. This coating is usually applied through methods like Chemical Vapor Deposition (CVD) or Physical Vapor Deposition (PVD).

Common Coating Materials:

Titanium Nitride (TiN) – Gold-colored, reduces friction.

Titanium Carbonitride (TiCN) – Good for high hardness and moderate heat.

Titanium Aluminum Nitride (TiAlN) – Great for high-temperature machining.

Aluminum Titanium Nitride (AlTiN) – Strong oxidation resistance.

Diamond-like Carbon (DLC) – Excellent for non-ferrous materials.

The coating’s purpose is to reduce wear, increase heat resistance, and improve surface finish during operation.

Key Differences Between Coated and Uncoated Tungsten Carbide

| Property | Coated Tungsten Carbide | Uncoated Tungsten Carbide |

|---|---|---|

| Surface Hardness | Higher due to coating | High, but lower than coated |

| Wear Resistance | Excellent — coating reduces abrasion | Good — but wears faster in abrasive conditions |

| Heat Resistance | Better — coating protects against heat | Moderate — can lose hardness faster at high heat |

| Friction | Lower — smoother cutting action | Higher — may cause more heat build-up |

| Cost | Higher upfront | Lower upfront |

| Best For | High-speed, high-heat, abrasive conditions | General purpose, softer materials, low-cost jobs |

Benefits of Coated Tungsten Carbide

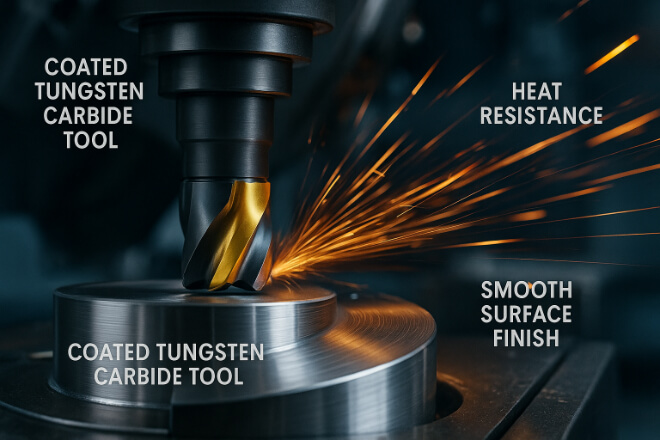

Coatings are not just for looks — they add real performance benefits.

1). Longer Tool Life

The coating creates a barrier between the workpiece and the tungsten carbide substrate, slowing down wear.

2). Higher Cutting Speeds

Lower friction means tools can run faster without overheating.

3). Better Surface Finish

Reduced friction helps prevent built-up edge and improves part quality.

4). Improved Heat Resistance

Coatings like TiAlN can handle extreme temperatures, making them ideal for dry machining.

Benefits of Uncoated Tungsten Carbide

Uncoated tools and parts still have advantages — especially in specific applications.

1). Lower Cost

Uncoated carbide costs less to produce and buy.

2). Sharper Cutting Edge

Without a coating layer, the edge can be ground to a sharper point, which is useful for cutting soft materials like aluminum or plastic.

3). No Risk of Coating Failure

In certain jobs, coatings can chip or peel; uncoated parts avoid this problem.

4). Easier to Regrind

Uncoated tools can be reground and reused without removing a coating layer.

Application Suitability

| Application | Recommended Option | Reason |

|---|---|---|

| High-speed steel replacement in machining | Coated Tungsten Carbide | Handles high heat and speed without losing hardness |

| Cutting aluminum or soft plastics | Uncoated Tungsten Carbide | Prevents built-up edge and keeps a sharp edge |

| Dry machining of hardened steel | Coated Tungsten Carbide | High heat resistance with TiAlN or AlTiN coating |

| Low-cost, short-run jobs | Uncoated Tungsten Carbide | Lower upfront cost and still durable for short runs |

| Mining drill bits for abrasive rock | Coated Tungsten Carbide | Extra wear protection in harsh environments |

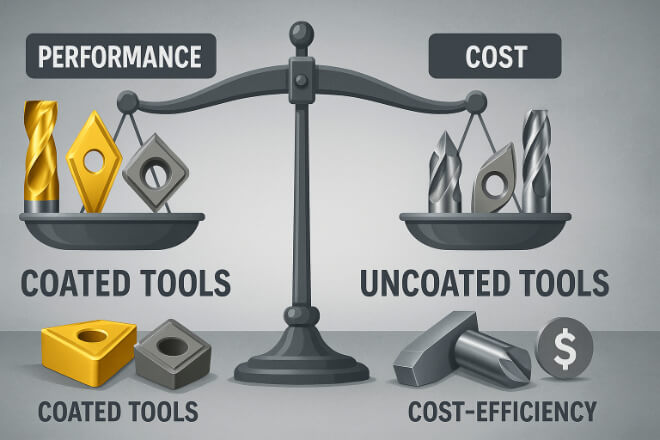

Cost vs. Performance

While coated tungsten carbide parts generally cost more upfront, they often last longer — reducing downtime and replacement costs.

Uncoated tungsten carbide can be cost-effective for short runs or softer materials where coating benefits are minimal.

For decision-makers, it is important to calculate total cost of ownership (TCO). Sometimes the higher purchase price of coated parts pays off through extended life and better performance.

Choosing the Right Option

When deciding between coated and uncoated tungsten carbide, consider:

Material you are processing (abrasive or soft)

Cutting speed and temperature

Budget and production volume

Downtime costs vs. tool cost

If your operations involve high-speed machining, abrasive materials, or high heat, coated tungsten carbide is usually worth the investment.

For low-cost jobs, softer materials, or small batches, uncoated tungsten carbide can be more economical.

Conclusion

Both coated and uncoated tungsten carbide have their place in industrial applications.

Coated tools shine in demanding, high-speed, high-heat conditions, while uncoated tools offer sharpness, lower cost, and ease of maintenance for less challenging jobs.

For business leaders, the decision should be based on application needs, cost efficiency, and expected performance. Testing both options in your specific environment is often the best way to find the right balance.

If you want to know more details about any company, please feel free to contact us.