Tungsten carbide bushings are valued for their durability and wear resistance.

However, if improperly aligned, they can suffer from out-of-round wear, which leads to uneven friction and premature failure.

This article will explain the causes of out-of-round wear, how misalignment affects the bushing, and best practices for ensuring proper alignment to prevent these issues.

What is Out-of-Round Wear?

Out-of-round wear occurs when a component, such as a tungsten carbide bushing, is no longer perfectly circular due to uneven wear or pressure.

This can happen if the bushing is misaligned during installation or during operation, causing the bushing to rotate unevenly within its housing or on the shaft.

Why Out-of-Round Wear Is a Concern:

Increased Friction: When the bushing is no longer round, the mating surfaces experience uneven contact, increasing friction and wear.

Reduced Efficiency: The uneven wear leads to a loss of efficiency in the system, as the bushing cannot perform optimally.

Premature Failure: Out-of-round wear can lead to early failure of the bushing, resulting in costly repairs and downtime.

Causes of Out-of-Round Wear

Several factors contribute to out-of-round wear in tungsten carbide bushings, with misalignment being the primary cause.

Understanding these factors can help in preventing the issue and ensuring the longevity of the bushings.

Key Causes of Out-of-Round Wear:

Misalignment during Installation: If the bushing is not properly aligned with the shaft or housing during installation, uneven pressure can be applied, leading to out-of-round wear.

Improper Shaft or Housing Fit: When the shaft or housing is not correctly sized for the bushing, it can cause irregular contact between the bushing and mating surface, resulting in uneven wear.

Vibration or Shock Loads: Excessive vibration or shock loads during operation can cause the bushing to shift or wear unevenly, leading to out-of-round conditions.

Inadequate Lubrication: Insufficient lubrication can increase friction between the bushing and the mating surface, accelerating uneven wear and leading to an out-of-round shape.

How Misalignment Affects Tungsten Carbide Bushings

Misalignment is one of the primary causes of out-of-round wear on tungsten carbide bushings.

Even a small misalignment can lead to uneven pressure distribution, which, over time, results in the bushing wearing in an irregular shape.

How Misalignment Causes Wear:

Pressure Points: Misalignment creates pressure points on the bushing, causing uneven wear on one side and increasing the risk of out-of-round conditions.

Uneven Rotation: When the bushing is not aligned properly, it can rotate unevenly, causing one side to wear faster than the other.

Reduced Performance: As the bushing becomes out of round, its ability to function efficiently decreases, leading to increased friction, higher temperatures, and reduced lifespan.

Best Practices for Preventing Out-of-Round Wear

To prevent out-of-round wear and ensure the longevity of tungsten carbide bushings, alignment checks should be conducted during installation and maintenance.

By following best practices, you can minimize the risk of misalignment and improve the performance of your bushings.

Best Practices for Proper Alignment:

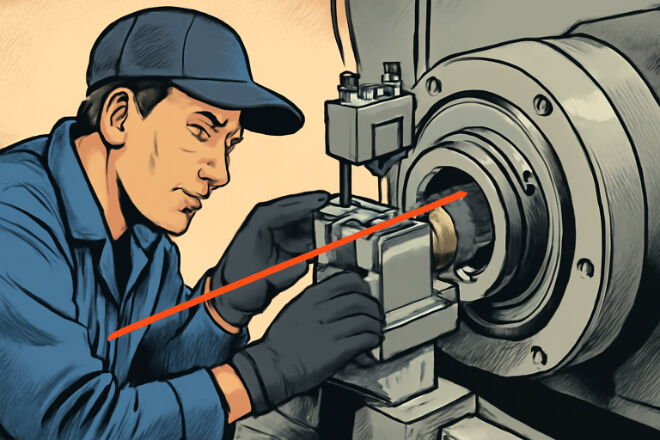

Use Alignment Tools: Ensure that proper alignment tools, such as laser alignment systems or dial indicators, are used to check the alignment of the bushing during installation.

Check Shaft and Housing Fit: Ensure that the shaft and housing are properly sized to fit the bushing. Using tolerances specified by the manufacturer ensures that the bushing fits snugly and securely, reducing the risk of misalignment.

Install with Even Pressure: When press-fitting the bushing, ensure that the force is applied evenly to prevent skewing the bushing or housing. Using a hydraulic press with controlled force is ideal.

Monitor for Vibration: Regularly check for excessive vibration or shock loads in the system. These factors can lead to misalignment and, consequently, out-of-round wear.

Maintain Lubrication: Ensure that the bushing is properly lubricated during operation. Lubrication reduces friction and helps prevent excessive wear and misalignment.

Tools and Techniques for Alignment Checks

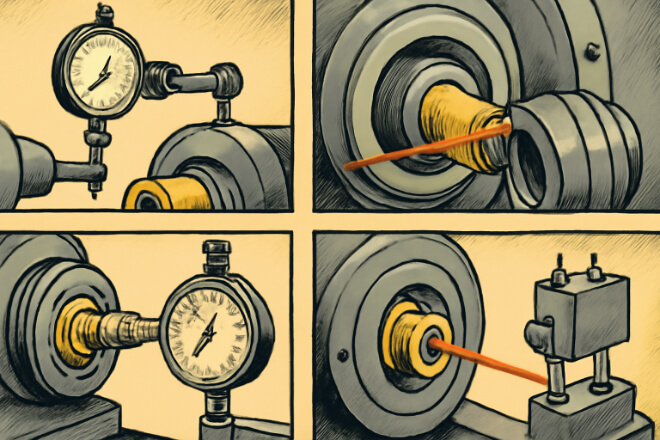

Proper alignment checks are crucial to preventing out-of-round wear. Various tools and techniques can be used to measure and correct alignment during installation and maintenance.

1). Alignment Tools:

Laser Alignment Systems: These systems provide precise alignment measurements and can help detect even minor misalignments during installation.

Dial Indicators: Used to measure the roundness of the bushing during installation, dial indicators can help identify any out-of-round conditions that need correction.

Micrometers and Calipers: These tools are used to measure the dimensions of the bushing and the shaft to ensure they are within tolerance and fit correctly.

2). Alignment Techniques:

Visual Inspection: Visually inspect the bushing and shaft to ensure that there is no visible misalignment.

Rotational Tests: Rotate the bushing after installation to check for any uneven wear patterns or signs of misalignment.

Tightness Check: Ensure that the bushing is firmly seated in the housing and the shaft is properly centered.

Monitoring and Maintaining Alignment Over Time

Once the bushing is installed and alignment is achieved, it’s important to continue monitoring and maintaining alignment during operation.

Misalignment can develop over time due to factors like wear, vibration, or changes in operating conditions.

Regular Maintenance Checks:

Vibration Monitoring: Install vibration sensors to monitor for any irregularities during operation that could indicate misalignment.

Lubrication Monitoring: Ensure that lubrication levels and quality are regularly checked. Poor lubrication can lead to increased wear and misalignment.

Routine Inspections: Periodically inspect the bushings and surrounding components to ensure they remain aligned and in good condition.

Conclusion

Misalignment and out-of-round wear are significant challenges when using tungsten carbide bushings.

By conducting regular alignment checks, using proper tools, and following best practices during installation and maintenance, you can prevent these issues and extend the lifespan of your bushings.

Proper alignment ensures optimal performance, reduces wear, and minimizes the risk of failure in critical machinery systems.

If you want to know more details about any company, please feel free to contact us.