فهم الكثافة في أدوات كربيد التنغستن

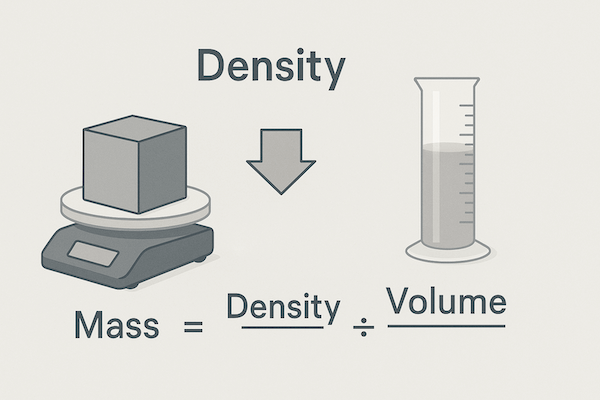

ما هي الكثافة؟ الكثافة خاصية فيزيائية أساسية تُشير إلى كتلة المادة لكل وحدة حجم. تُعبَّر عنها عادةً بالغرام لكل سنتيمتر مكعب (جم/سم³) أو بالكيلوغرام لكل متر مكعب (كجم/م³). صيغتها بسيطة: الكثافة = الكتلة ÷ الحجم. تلعب هذه الخاصية دورًا حاسمًا في اختيار المواد، حيث [...]

فهم مقاومة الكسر في أدوات كربيد التنغستن

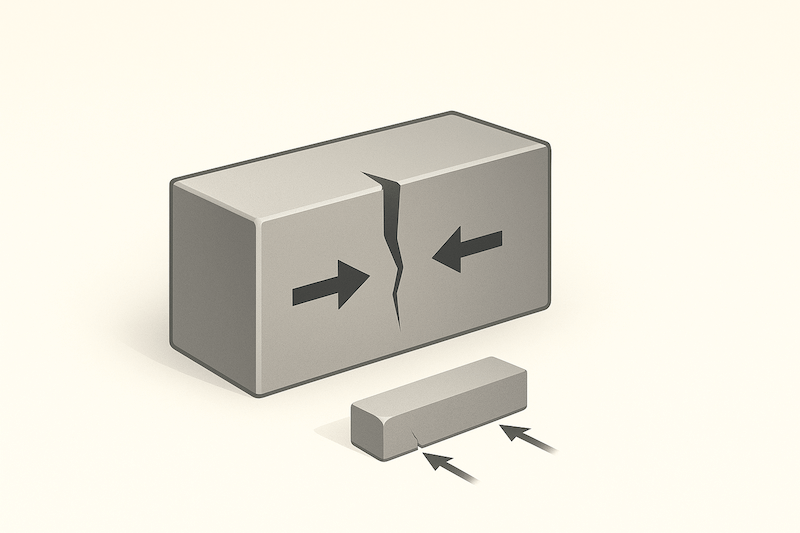

ما هي متانة الكسر؟ متانة الكسر هي قدرة المادة على مقاومة انتشار الشقوق. تُحدد هذه المتانة مدى قدرة المادة على تحمل الإجهاد في حال وجود عيب أو عيب، وهي بالغة الأهمية في المواد الهشة. تُرمز لمتانة الكسر عادةً بـ K₁c وتُقاس بوحدة ميجا باسكال. كلما زادت قيمة K₁c [...]

فهم قوة الشد في أدوات كربيد التنغستن

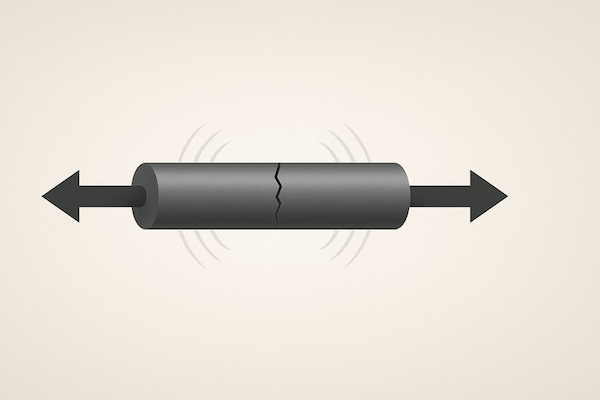

ما هي قوة الشد؟ تشير قوة الشد إلى أقصى إجهاد يمكن للمادة تحمله أثناء الشد أو السحب قبل الانكسار. وهي خاصية ميكانيكية أساسية، تُقاس عادةً بالميجا باسكال (MPa) أو رطل لكل بوصة مربعة (psi)، وتمثل مقاومة المادة للسحب. ببساطة، قوة الشد تُشير إلى [...]

فهم مقاومة التآكل في أدوات كربيد التنغستن

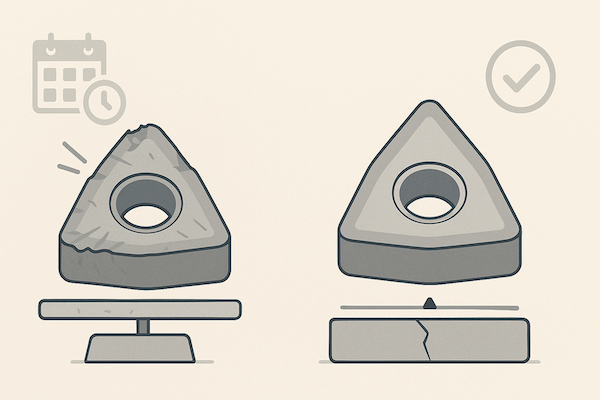

ما هي مقاومة التآكل؟ تشير مقاومة التآكل إلى قدرة المادة على تحمل التلف السطحي التدريجي الناتج عن الاحتكاك أو التآكل أو التآكل الميكانيكي أو التلامس مع مواد أخرى. وهي خاصية أساسية في المواد المستخدمة في بيئات عالية الاحتكاك أو الإجهاد، إذ تؤثر بشكل مباشر على عمر خدمة المكونات وأدائها. المواد ذات [...]