علامات تشير إلى أنه حان الوقت لاستبدال أدوات القطع المصنوعة من كربيد التنجستن

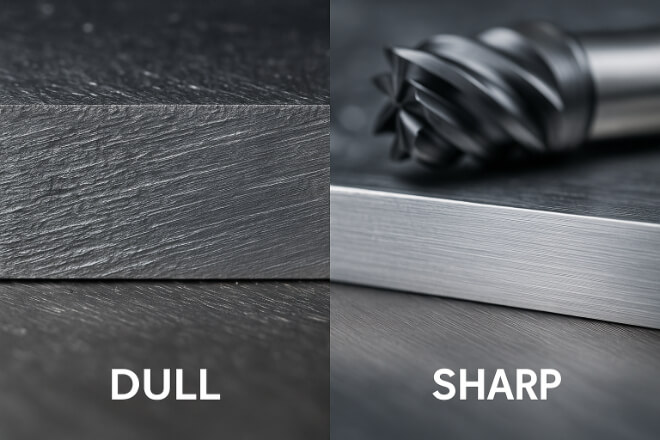

تشتهر أدوات القطع المصنوعة من كربيد التنغستن بمتانتها الفائقة وعمرها الطويل. ولكن كأي أداة أخرى، فإنها تتآكل مع مرور الوقت. قد يؤدي استخدام أداة باهتة أو تالفة إلى إتلاف قطعتك، وإبطاء ماكيناتك، بل وحتى التسبب في مشاكل أكثر خطورة. إذا كنت تدير ورشة أو مسؤولاً عن ضمان سلاسة الإنتاج، فإن معرفة متى يجب استبدالها [...]

لماذا يُعد اختيار المورد المناسب أمرًا مهمًا لأدوات القطع المصنوعة من كربيد التنجستن

في عالم الآلات الدقيقة والتصنيع الصناعي، تلعب أدوات قطع كربيد التنغستن دورًا محوريًا. تشتهر هذه الأدوات بصلابتها ومقاومتها للتآكل وقدرتها على تحمل القطع عالي السرعة في المواد الصلبة. ولكن هناك عامل رئيسي يغفله العديد من صانعي القرار: المورد الذي يقف وراء الأداة. اختيار المورد المناسب لـ [...]

العوامل المؤثرة على تكلفة أدوات القطع المصنوعة من كربيد التنجستن

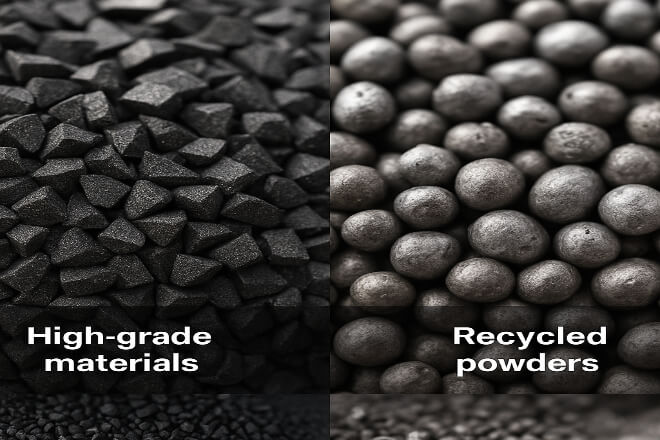

تُعد أدوات القطع المصنوعة من كربيد التنغستن أساسية في العديد من الصناعات، بدءًا من صناعة السيارات والفضاء وصولًا إلى صناعة القوالب والتشغيل الآلي. تشتهر هذه الأدوات بمتانتها ومقاومتها للحرارة وعمرها الافتراضي الطويل. ومع ذلك، يتساءل خبراء الشراء وصانعو القرار: لماذا تُكلف أدوات كربيد التنغستن هذه المبالغ؟ إن فهم أسعار هذه الأدوات يُساعد [...]

دحض الخرافات الشائعة حول أدوات القطع المصنوعة من كربيد التنغستن

تُستخدم أدوات قطع كربيد التنغستن على نطاق واسع في صناعات مثل صناعة الطيران والسيارات والتصنيع العام. وهي معروفة بمتانتها ودقتها وقدرتها على قطع المواد الصلبة. ومع ذلك، لا يزال هناك الكثير من المفاهيم الخاطئة حول آلية عمل هذه الأدوات، ومدة عمرها، وتكلفتها. غالبًا ما تؤدي هذه الخرافات إلى سوء الشراء [...]

كيفية تقليل تآكل الأدوات باستخدام أدوات القطع المصنوعة من كربيد التنجستن

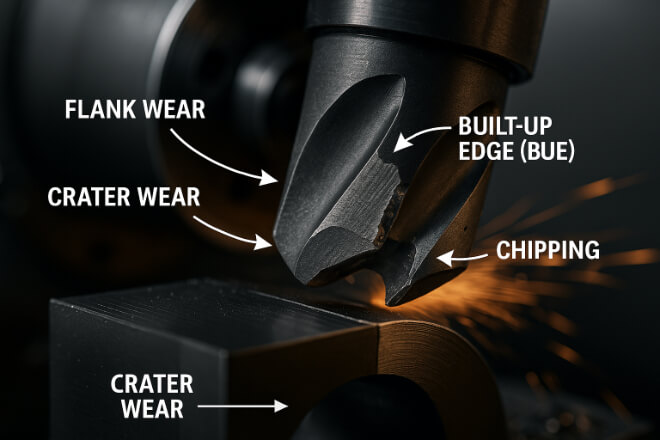

تحظى أدوات القطع المصنوعة من كربيد التنغستن بثقة واسعة في العديد من الصناعات بفضل قوتها ودقتها وأدائها طويل الأمد. ولكن حتى أقوى الأدوات تتآكل بمرور الوقت. بالنسبة لصانعي القرار في شركات التصنيع والتشغيل الآلي، فإن تقليل تآكل الأدوات ليس مجرد تحدٍّ تقني، بل هو خطوة عملية ذكية. فانخفاض التآكل يعني انخفاض التكاليف، وتحسين الإنتاجية، وتقليل الانقطاعات. في [...]

القطع الدقيق باستخدام كربيد التنغستن: أفضل الممارسات والنصائح

عندما يتعلق الأمر بقطع دقيق ونظيف في الآلات، غالبًا ما تُعدّ أدوات كربيد التنغستن الخيار الأمثل. فهي أصلب من الفولاذ عالي السرعة، وأكثر مقاومة للحرارة، وتوفر أداءً أفضل في التطبيقات عالية السرعة. لكن مجرد امتلاك أداة كربيد لا يكفي، بل يجب استخدامها بالطريقة الصحيحة أيضًا. في هذا الدليل، سنشرح لك [...]

التأثير البيئي لاستخدام أدوات القطع المصنوعة من كربيد التنجستن

في عالمنا اليوم، يهتم الناس بالاستدامة أكثر من أي وقت مضى. بدءًا من الخيارات الشخصية ووصولًا إلى العمليات الصناعية، يسعى الجميع إلى تقليل النفايات وتوفير الطاقة واتخاذ قرارات أفضل لكوكب الأرض. ولكن عندما نتحدث عن الآلات والتصنيع، غالبًا ما يُغفل الأثر البيئي. وهنا تبرز أهمية أدوات القطع المصنوعة من كربيد التنغستن. [...]

كيفية تحديد أدوات القطع المصنوعة من كربيد التنجستن عالية الجودة

عند العمل على ماكينات CNC أو أي تطبيق عالي الدقة، فإن الأدوات التي تختارها قد تُؤثر على نتائجك. تُعد أدوات القطع المصنوعة من كربيد التنغستن شائعة الاستخدام لمتانتها وعمرها الطويل وكفاءتها العالية في التشغيل الآلي. ولكن ليست جميع أدوات الكربيد متساوية. في هذا الدليل، سنشرح لك كيفية تحديد ما إذا كانت [...]

دور الطلاءات في تحسين أداء أدوات القطع المصنوعة من كربيد التنجستن

تشتهر أدوات القطع المصنوعة من كربيد التنغستن بقوتها ومتانتها. ولكن حتى أكثر الأدوات صلابةً قد تتآكل بسرعة في الظروف القاسية. وهنا يأتي دور الطلاء. فاستخدام الطلاء المناسب يُحدث فرقًا كبيرًا في عمر أداتك، وكفاءتها في القطع، ومقدار ما توفره من مال في [...]

المشاكل الشائعة والحلول لأدوات القطع المصنوعة من كربيد التنغستن

تشتهر أدوات القطع المصنوعة من كربيد التنغستن بصلابتها وعمرها الطويل. تُستخدم غالبًا في ماكينات التحكم الرقمي بالكمبيوتر، وصناعة الطيران، والسيارات، والعديد من الصناعات الأخرى عالية الدقة. ولكن حتى هذه الأدوات المتينة قد تواجه مشاكل إذا لم تُستخدم أو تُصان بشكل صحيح. في هذه المقالة، سنتناول أكثر المشاكل شيوعًا التي يواجهها الناس [...]