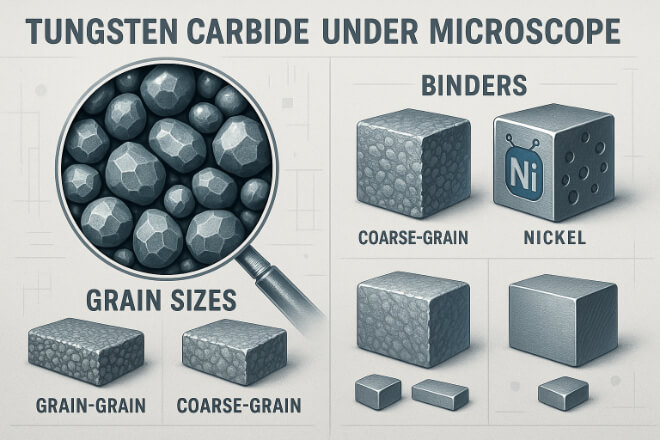

كيفية اختيار الدرجة المناسبة من كربيد التنجستن لأجزاء التآكل

تُستخدم قطع كربيد التنغستن المقاومة للتآكل في الصناعات التي تتعرض فيها الأدوات لتآكل شديد أو حرارة أو صدمات. ولكن ليست جميع أنواع كربيد التنغستن متماثلة. تُصنع درجات مختلفة من كربيد التنغستن لتحمل ظروف عمل مختلفة. قد يؤدي اختيار الدرجة الخاطئة إلى تعطل مبكر، وارتفاع التكاليف، وتوقف العمل. يضمن اختيار الدرجة المناسبة أقصى عمر للأداة وأدائها. [...]

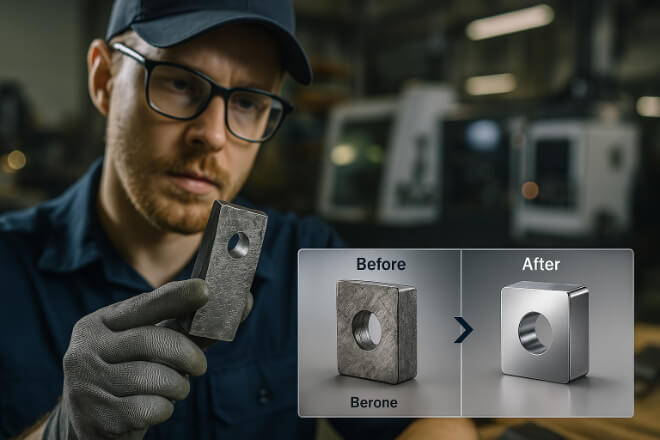

تجديد وإعادة تدوير أجزاء تآكل الكربيد

تشتهر قطع كربيد التنغستن المقاومة للتآكل بمتانتها وصلابتها ومقاومتها للتآكل. تُستخدم في العديد من الصناعات، مثل التعدين والنفط والغاز والتصنيع والنجارة. مع مرور الوقت، حتى أقوى قطع الكربيد تتآكل. بدلاً من استبدالها بمكونات جديدة، يمكن للشركات اختيار إعادة تأهيلها أو إعادة تدويرها لتوفير المال وحماية [...]

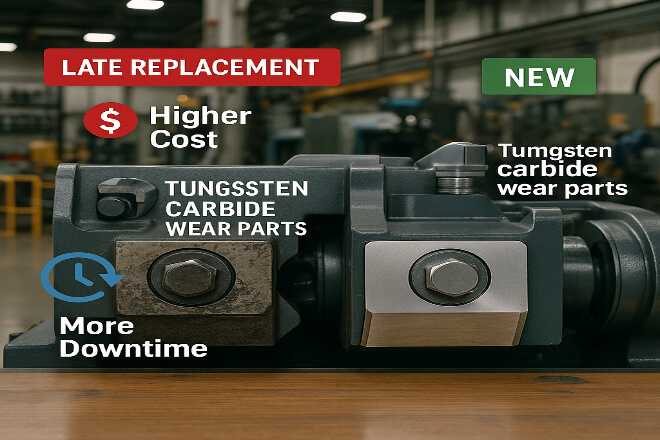

متى وكيف يتم استبدال مكونات كربيد التنجستن المقاومة للتآكل

تُستخدم مكونات كربيد التنغستن المقاومة للتآكل في صناعات مثل التعدين والنفط والغاز والتصنيع وتشكيل المعادن، نظرًا لصلابتها العالية ومقاومتها للتآكل وعمرها الافتراضي الطويل. ورغم أنها أقوى بكثير من الفولاذ، إلا أنها معرضة للتآكل أو التلف في النهاية. بالنسبة لصانعي القرار، فإن معرفة وقت استبدال هذه المكونات أمرٌ أساسي لتجنب التكاليف الباهظة [...]

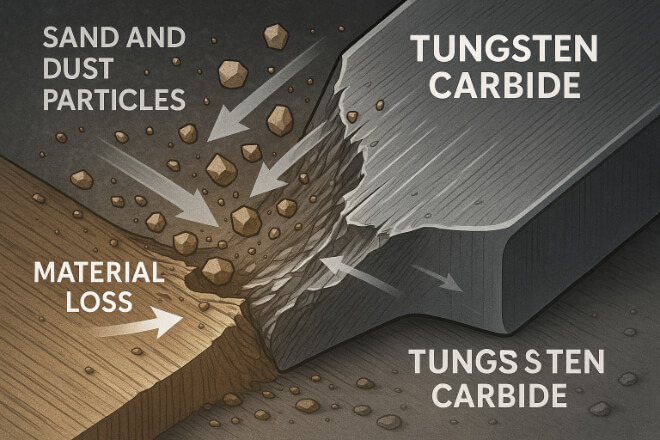

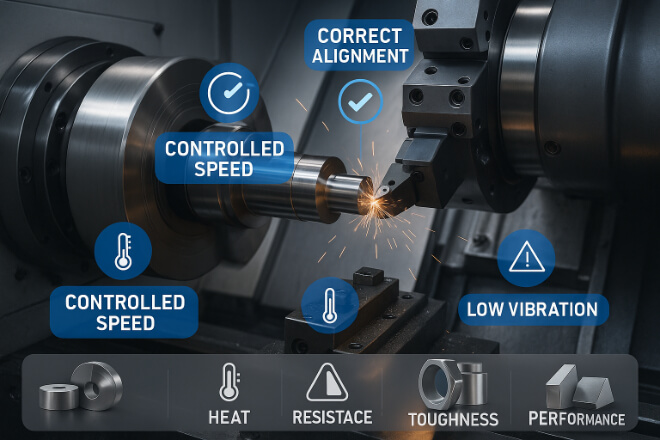

الأعطال الشائعة لأجزاء التآكل وكيفية منعها

تُعد قطع الغيار المقاومة للتآكل مكونات أساسية في الآلات الثقيلة، ومعدات التصنيع، وأدوات التعدين، والعديد من الأنظمة الصناعية الأخرى. وهي مصممة لتحمل أقصى قدر من الإجهاد والتآكل أثناء التشغيل، مما يحمي باقي أجزاء الآلة من التلف. ومع ذلك، حتى أقوى المواد - مثل كربيد التنغستن، والفولاذ المقسى، والسيراميك - قد تتلف إذا لم تُنتقى بعناية، وتُصان، [...]

كيفية إطالة عمر أجزاء تآكل كربيد التنغستن

تتميز قطع كربيد التنغستن المقاومة للتآكل بصلابتها العالية ومقاومتها للتآكل وعمرها الافتراضي الطويل. تُستخدم في صناعات مثل التعدين والنفط والغاز وتشكيل المعادن والتصنيع، حيث تعمل المعدات في بيئات قاسية. ومع ذلك، حتى أفضل قطع كربيد التنغستن قد تتعطل مبكرًا إذا لم تُستخدَم وتُصان بشكل صحيح. [...]