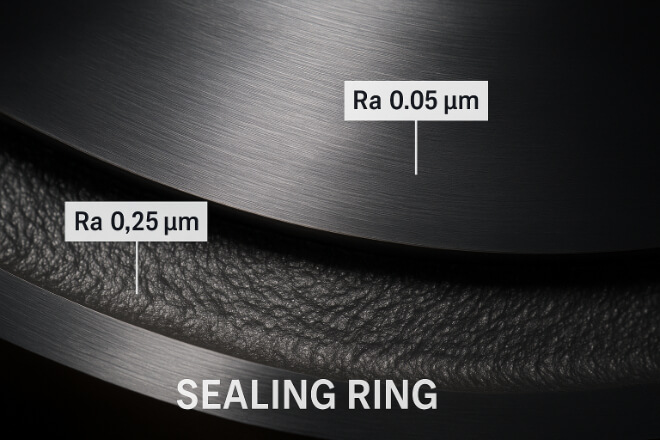

تضاريس سطح حلقات الختم: ماذا يعني Ra 0.04–0.05 ميكرومتر حقًا

في الأختام الميكانيكية، تؤثر تضاريس سطح حلقات الختم بشكل مباشر على التحكم في التسرب، واحتباس التزييت، ومقاومة التآكل. غالبًا ما تُحدد قيمة Ra بين 0.04 و0.05 ميكرومتر للتطبيقات عالية الأداء، ولكن قد يتساءل العديد من صانعي القرار عن المعنى الحقيقي لهذا الرقم وأهميته. تشرح هذه المقالة Ra بين 0.04 و0.05 ميكرومتر بشكل مبسط، وتأثيرها [...]

تحقيق تشطيبات بمستوى المرآة على حلقات ختم الكربيد: نوافذ العملية والمزالق

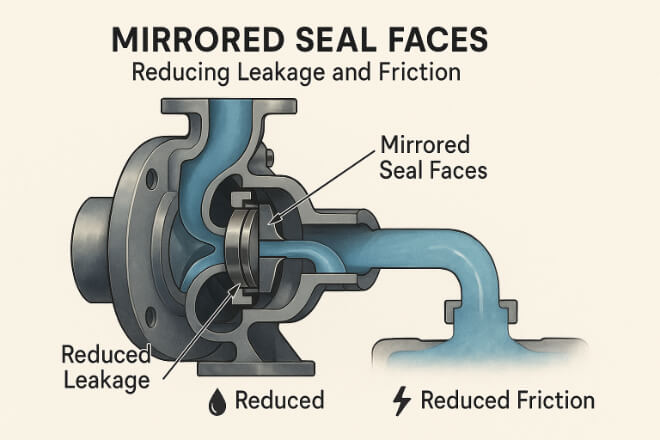

حلقات مانعة للتسرب من الكربيد مُكوّنات أساسية في المضخات والضواغط والصمامات في صناعات مثل النفط والغاز، والمعالجة الكيميائية، وتوليد الطاقة، والأنظمة البحرية. يضمن الحصول على تشطيب بمستوى المرآة لهذه الحلقات التحكم في التسرب، وانخفاض الاحتكاك، وإطالة عمر المعدات. ومع ذلك، فإن تحقيق تشطيب بمستوى المرآة المثالي ليس بالأمر السهل، إذ يتطلب فترات زمنية صارمة للعمليات، [...]

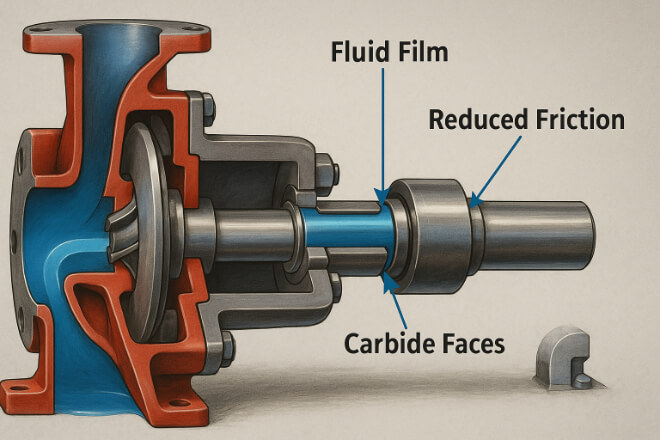

التشطيبات فائقة النعومة مقابل التشطيبات ذات الجيوب الدقيقة: احتباس التزييت على أسطح الكربيد

في الأختام الميكانيكية، لا يؤثر تشطيب أسطح الكربيد على التحكم في التسرب فحسب، بل يؤثر أيضًا على احتباس التزييت. هناك طريقتان شائعتان للتشطيب - تشطيبات فائقة النعومة وتشطيبات ذات جيوب دقيقة - توفران مزايا مختلفة حسب ظروف التشغيل. بالنسبة لصانعي القرار في صناعات مثل النفط والغاز، والمعالجة الكيميائية، والأنظمة البحرية، وتوليد الطاقة، فإن فهم هذه التشطيبات يساعد على تحسين أداء الأختام، [...]

حلقات التكييف، واختيار اللوحة، والتحكم في الملاط لتلميع سطح الكربيد

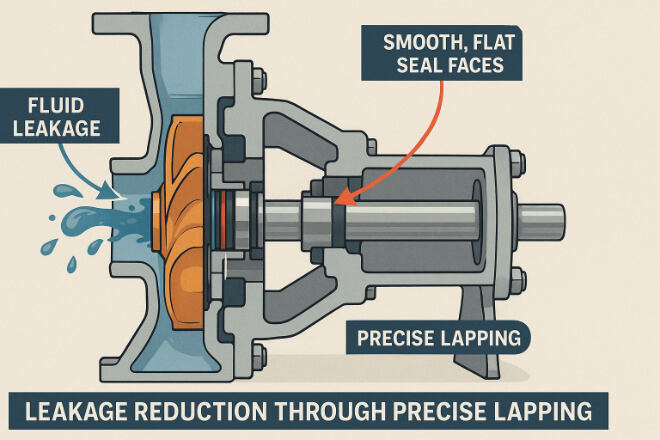

في تصنيع وصيانة الأختام الميكانيكية، يُعدّ تلميع سطح الكربيد عملية تشطيب أساسية. يضمن التلميع الجيد استواء السطح، وانخفاض خشونة السطح (Ra)، وأداءً مُحكمًا للختم. تُحدد ثلاثة عوامل رئيسية - حلقات التكييف، واختيار لوحة التلميع، والتحكم في الملاط - جودة التشطيب وإمكانية تكراره. يشرح هذا الدليل كيفية تأثير هذه العناصر على تلميع سطح الكربيد، ويُقدم [...]

هدف Ra والتسطيح لأوجه ختم الكربيد: أفضل ممارسات التلميع والتلميع

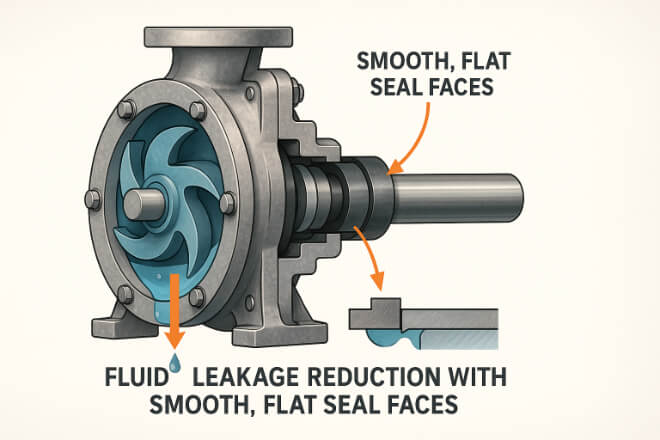

تُعدّ أسطح مانعات التسرب المصنوعة من الكربيد بالغة الأهمية للمضخات والضواغط والصمامات في صناعات مثل النفط والغاز، وتوليد الطاقة، والمعالجة الكيميائية، ومعالجة المياه. تؤثر خشونة السطح (Ra) واستواء هذه الأسطح بشكل مباشر على التحكم في التسرب، ومقاومة التآكل، وموثوقية المعدات. يُعدّ التلميع والتلميع عمليتين أساسيتين للتشطيب، تُحددان Ra النهائي [...]