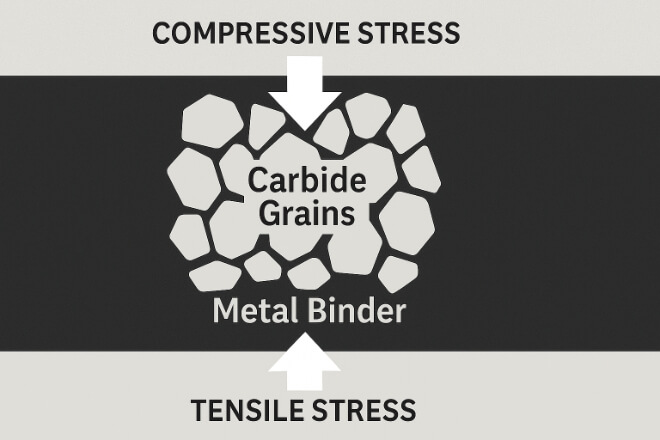

Stress, Load, and Thermal Expansion Analysis in Tungsten Carbide Bushings

Tungsten carbide bushings are widely used in pumps, compressors, turbines, and mechanical seals — where they must handle high pressure, speed, and temperature. To work reliably, these bushings must maintain their shape, strength, and fit under stress, load, and temperature changes. If not properly designed or analyzed, they may crack, deform, or seize, leading to […]

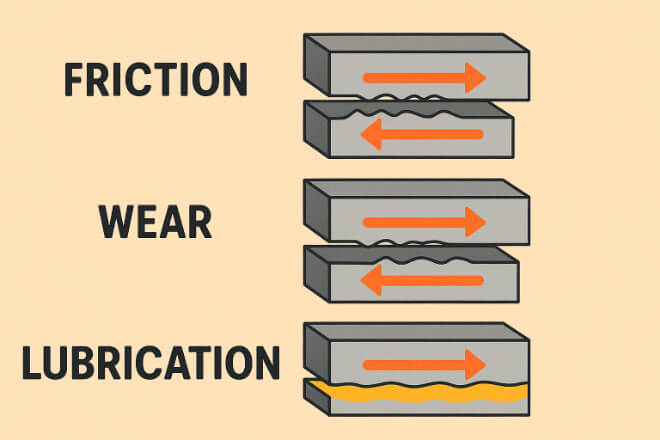

Tribology and Friction Behavior of Tungsten Carbide Bushings

In modern mechanical systems, friction control plays a key role in efficiency and durability. Whether in pumps, compressors, or turbines, every moving part relies on bushings or bearings to reduce wear and maintain stability. Among many materials used, tungsten carbide bushings stand out for their exceptional tribological performance — the science of friction, wear, and […]

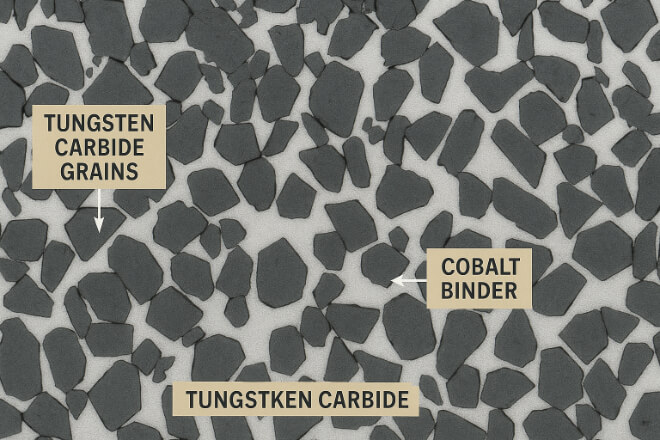

How Microstructure Affects the Performance of Tungsten Carbide Bushings

The microstructure of tungsten carbide bushings plays a key role in determining how well they perform under wear, heat, and pressure. While many buyers focus on grade codes like YG6 or YG8, the real story lies inside — in the arrangement of carbide grains and binder metal. For decision-makers in industries such as oil & […]

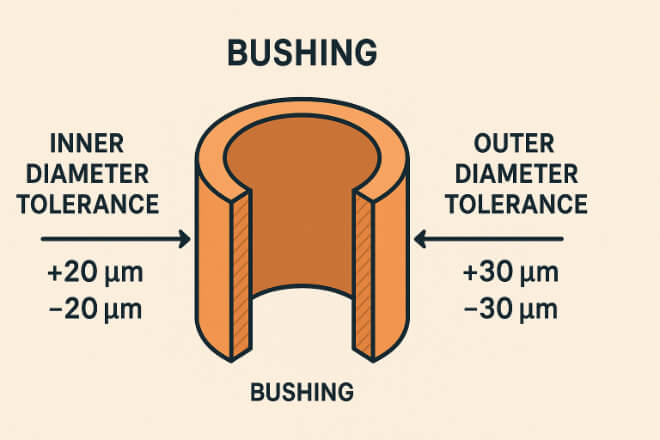

Dimensional Tolerances and Surface Finish in Tungsten Carbide Bushings

When engineers select tungsten carbide bushings for pumps, compressors, or turbines, they often focus on hardness and wear resistance. But two equally critical parameters are dimensional tolerance and surface finish. These two factors determine how well the bushing fits the shaft, how smoothly it operates, and how long it lasts. Even a small deviation — […]

How to Evaluate Supplier Quality for Tungsten Carbide Bushings

When sourcing tungsten carbide bushings, quality is not just about the product — it’s about the supplier behind it. A good supplier can ensure consistent performance, fast delivery, and long-term reliability. A poor supplier, on the other hand, can lead to production delays, early wear, or even equipment damage. For decision-makers in oil & gas, […]