The Benefits of Tungsten Carbide Tips in Extreme Temperature Applications

Many industrial cutting and drilling operations work under extreme temperature conditions. High heat or sudden temperature changes can quickly damage standard tool materials, leading to fast wear, tool failure, and high costs. Tungsten carbide tips are widely used in these harsh environments because they keep their strength and cutting ability even when temperatures rise or […]

How Tungsten Carbide Tips Improve Material Removal Rates in Milling Machines

In modern milling operations, material removal rate (MRR) is one of the most important factors affecting productivity and cost. Higher material removal rates mean faster machining, shorter cycle times, and better use of machine capacity. However, increasing MRR is not easy when tools wear quickly or lose cutting stability. Tungsten carbide tips play a key […]

Tungsten Carbide Tips for Enhanced Cutting in High-Vibration Environments

In industries such as manufacturing, construction, and aerospace, high-vibration environments are common during cutting and drilling operations. These vibrations can lead to tool wear, poor surface finishes, and a decrease in cutting precision. To overcome these challenges, tungsten carbide tips have become the go-to solution for many high-vibration applications. Due to their hardness, toughness, and […]

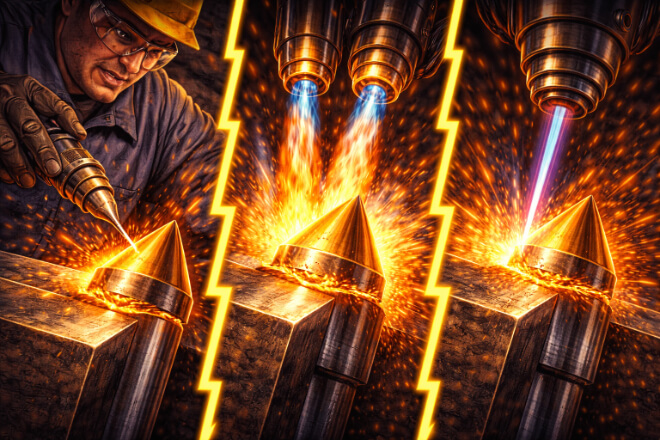

Optimizing the Bonding Process of Tungsten Carbide Tips for Better Durability

In industries like mining, drilling, and machining, the durability of tools is essential for maintaining productivity and minimizing costs. Tungsten carbide tips are commonly used for their hardness, wear resistance, and overall durability. However, the process of bonding tungsten carbide to a metal substrate is a critical factor in determining the tool’s long-term performance. Optimizing […]