تُستخدم أجزاء الكربيد على نطاق واسع في الصناعات مثل التعدين, النفط والغاز, السيارات, الفضاء الجوي, تشغيل المعادن، والتصنيع. قيمتها الرئيسية تأتي من مقاومة التآكل, صلابة، وعمر خدمة طويل.

مع ذلك، لا تُصنع جميع قطع الكربيد بنفس الجودة. بالنسبة للشركات التي تعتمد على أدوات الكربيد وقطع الغيار المقاومة للتآكل، يُعدّ ضمان استيفاء هذه المنتجات لمعايير شهادة الأيزو والاختبار أمرًا بالغ الأهمية.

تشرح هذه المقالة كيفية عمل شهادة ISO، ولماذا يعد اختبار مقاومة التآكل مهمًا، وما هي الخطوات التي يجب على صناع القرار اتخاذها للتحقق من أن موردي الكربيد لديهم يقدمون منتجات أصلية وموثوقة.

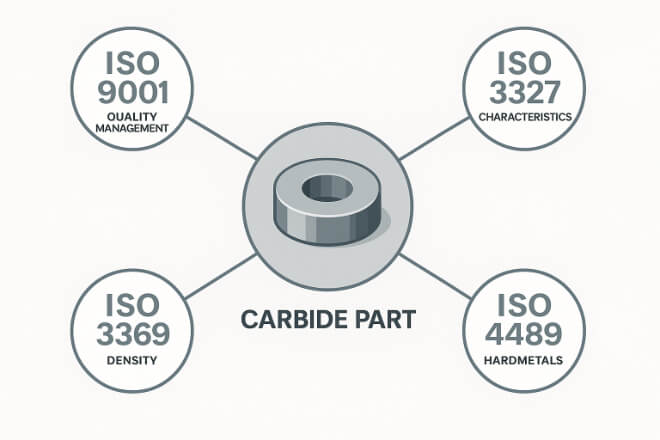

لماذا تُعدّ شهادة ISO مهمة لأجزاء الكربيد

تضع المنظمة الدولية للمعايير (ISO) معايير عالمية لضمان الجودة والسلامة والاتساق. بالنسبة لقطع الكربيد، تُثبت شهادة ISO أن الشركة المصنعة:

تتبع أنظمة إدارة الجودة الصارمة (ISO 9001).

يلبي معايير الاختبار صلابة, صلابة، و مقاومة التآكل.

يستخدم طرق التفتيش المناسبة والمعدات المعايرة.

يوفر إمكانية التتبع للمواد الخام والأجزاء النهائية.

بالنسبة لصناع القرار، فإن العمل مع مورد حاصل على شهادة ISO يقلل من خطر تلقي أجزاء كربيد رديئة الجودة أو مزيفة.

كما أنه يساعد على تلبية المتطلبات التنظيمية أو الخاصة بالصناعة في أسواق مثل النفط والغاز والفضاء والسيارات.

معايير ISO الشائعة لمنتجات الكربيد

ترتبط العديد من معايير ISO ارتباطًا مباشرًا بأجزاء كربيد التنغستن. من أبرزها:

ISO 9001 – أنظمة إدارة الجودة

ضمان اتباع الشركات المصنعة للعمليات المنظمة للإنتاج والتفتيش وخدمة العملاء.

ISO 45001 – الصحة والسلامة

يؤكد ممارسات مكان العمل الآمن أثناء إنتاج الكربيد، وهو أمر مهم بسبب التعامل مع الكوبالت.

ISO 14001 – الإدارة البيئية

يظهر التزامه بالتصنيع المستدام والحد من النفايات.

ISO 3327 – اختبار صلابة الكربيدات الأسمنتية

يحدد كيفية قياس صلابة الكربيد باستخدام طرق روكويل أو فيكرز.

ايزو 3369 – كثافة تحديد المعادن الصلبة

يحدد طريقة اختبار الكثافة و المسامية المستويات.

ايزو 3738 – مقاومة الكسر ومقاومة التشقق

يحدد الاختبار للتقييم صلابة من الكربيدات الأسمنتية.

ISO 4499 – التحديد المعدني لحجم الحبيبات

يقدم إرشادات للتحقق من البنية الدقيقة وتوزيع حبيبات WC.

تساعد هذه المعايير على ضمان أن أجزاء الكربيد لها تناسق مقاومة التآكل والأداء الميكانيكي.

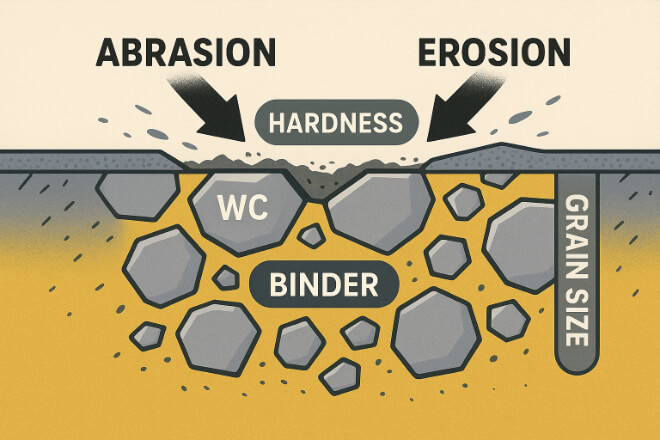

فهم مقاومة التآكل في أجزاء الكربيد

مقاومة التآكل تعني مدى قدرة قطع الكربيد على تحمل الاحتكاك والتآكل والتآكل وإجهاد التلامس أثناء التشغيل. تُعد هذه الخاصية الأهم لأنها تؤثر بشكل مباشر على:

عمر الأداة وتكلفة الاستبدال

كفاءة الإنتاج ووقت التوقف

حماية الآلات والسلامة

موثوقية المنتج في التطبيقات الحرجة

تتأثر مقاومة التآكل للكربيد بما يلي:

كيفية اختبار مقاومة التآكل

تُرشد معايير ISO طرق اختبار مختلفة لمقاومة تآكل الكربيد. ومن أكثرها شيوعًا:

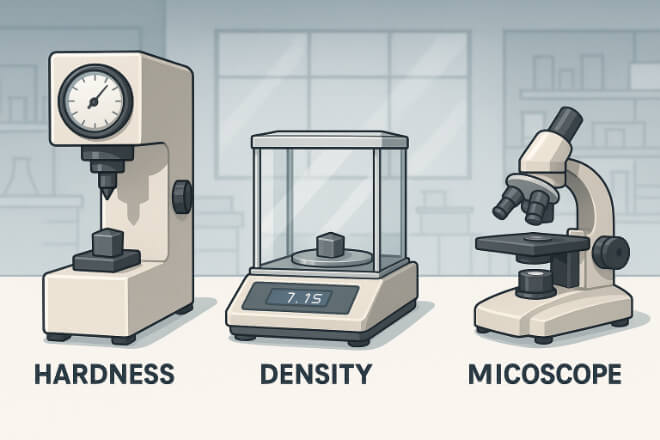

1) اختبار الصلابة (ISO 3327)

تقيس اختبارات صلابة روكويل A (HRA) وفيكرز صلابة الكربيد.

تتراوح أجزاء الكربيد النموذجية من HRA 89.5 إلى 92.5.

عادة ما تعني الصلابة الأعلى درجة أعلى مقاومة التآكل.

2). كثافة و المسامية الاختبار (ISO 3369)

تشير الكثافة إلى تماسك المادة.

كثافة الكربيد القياسية هي 14.5 – 15.0 جم / سم³.

تؤدي المسامية العالية إلى تقليل مقاومة التآكل والقوة.

3). مقاومة الكسر الاختبار (ISO 3738)

قياس مقاومة التشقق.

يضمن أن أجزاء الكربيد قادرة على تحمل الصدمات والضغط دون فشل.

4) اختبار التآكل والتآكل

تحاكي اختبارات التآكل الانزلاقي الاحتكاك ضد المعادن.

تستخدم اختبارات التآكل جزيئات أو سوائل كاشطة.

تساعد النتائج على مقارنة درجات الكربيد المختلفة.

5) التحليل المعدني (ISO 4499)

التحليل المجهري لبنية الحبوب.

يؤكد توزيع WC الموحد وجودة مرحلة الرابط.

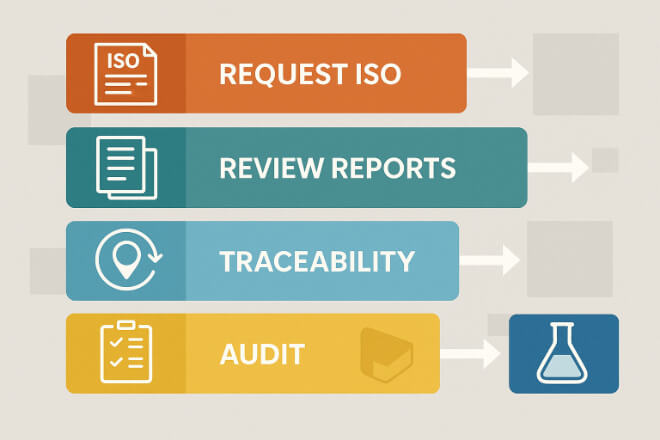

دور الشهادات في تقييم الموردين

بالنسبة لصانعي القرار، تُعدّ شهادات واختبارات ISO أدواتٍ مهمة لاختيار الموردين. عند تقييم مورد كربيد:

اطلب شهادات الأيزو (9001، 14001، 45001).

طلب تقارير الاختبار ل صلابة, كثافة، و مقاومة التآكل.

تأكد من أنهم يتبعون عمليات التدقيق والتفتيش على الجودة بشكل منتظم.

تأكيد إمكانية التتبع من المسحوق الخام إلى الأجزاء النهائية.

يجب التعامل مع المورد الذي لا يستطيع تقديم مستندات ISO ونتائج الاختبارات باعتباره مصدر خطر.

فوائد اختيار قطع الكربيد المعتمدة من ISO

إن العمل مع الموردين الحاصلين على شهادة ISO يمنح العديد من الفوائد:

جودة ثابتة - كل دفعة تلبي نفس المعايير.

تحسين الموثوقية - تدوم الأدوات لفترة أطول وتعمل بشكل أفضل.

تقليل وقت التوقف عن العمل – انخفاض فشل الأدوات وانخفاض توقف الماكينة.

انخفاض التكاليف - عمر الأداة الأطول يقلل من الحاجة إلى الاستبدال.

الامتثال التنظيمي - يلبي معايير الصناعة والحكومة.

ثقة العملاء – من الأسهل الفوز بالعقود عند استخدام الأجزاء المعتمدة.

للصناعات مثل النفط والغاز, الفضاء الجوي، و السياراتإن الحصول على كربيد معتمد وفقًا لمعايير ISO ليس أمرًا اختياريًا - بل إنه غالبًا ما يكون متطلبًا.

مثال حالة: مقاعد صمامات الكربيد في النفط والغاز

صمام مقاعد في النفط والغاز تتعرض معدات الحفر للتآكل الشديد بسبب الرمال والسوائل والضغط العالي.

قد يتآكل المقعد غير المعتمد بسرعة، مما يتسبب في حدوث تسربات وتوقف عن العمل.

مقعد كربيد تم اختباره وفقًا لمعايير ISO مع صلابة HRA 92 و كثافة قد تدوم 14.9 جرام/سم³ خمس مرات أطول.

يوضح هذا المثال كيف يمكن للشهادات والاختبارات أن تساهم بشكل مباشر في توفير التكاليف وتحسين الموثوقية في الصناعات الحيوية.

خطوات لصناع القرار لضمان الأصالة

طلب شهادات ISO – التحقق من صحتها وتحديثها.

مراجعة تقارير الاختبار – صلابة, كثافة, صلابة، و اختبار التآكل.

اسأل عن إمكانية التتبع – المسحوق الخام والمعالجة والتفتيش النهائي.

قم بزيارة الموردين أو التدقيق عليهم - إذا كان ذلك ممكنًا، راجع عملياتهم ومختبراتهم.

استخدم الاختبارات المستقلة - بالنسبة للطلبات الكبيرة، قم بتأكيد النتائج مع مختبرات تابعة لجهات خارجية.

خاتمة

إن الحصول على شهادة ISO واختبار مقاومة التآكل ليس مجرد تفاصيل تقنية، بل هي ضمانات مهمة للأعمال بالنسبة لصناع القرار.

من خلال اختيار موردي الكربيد المعتمدين من ISO والتحقق من مقاومة التآكل من خلال الاختبار المناسب، يمكن للشركات حماية آلاتها وتقليل وقت التوقف عن العمل وضمان الموثوقية على المدى الطويل.

في الصناعات التي لا يعتبر فيها الفشل خيارًا، تعد شهادة ISO دليلاً على الثقة والأداء.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.