Desalination and brackish water pumps work under harsh conditions—high salinity, abrasive particles, and constant pressure.

Reliable sealing is critical to prevent leaks, maintain efficiency, and reduce downtime.

حلقات ختم كربيد التنغستن are widely used in these systems because of their durability, مقاومة التآكل، وعمر خدمة طويل.

This article explains their advantages, applications, and best practices for decision-makers.

Why Desalination and Brackish Water Pumps Need Strong Seals

Prevent leaks → Protects expensive equipment and prevents contamination.

Maintain pump efficiency → Reliable seals reduce friction and energy waste.

Handle high salinity → Saltwater is corrosive to weaker materials.

Reduce downtime → Avoid unplanned maintenance and expensive repairs.

Protect the environment → Prevents saline leaks that could harm ecosystems.

خصائص حلقات ختم كربيد التنغستن

Tungsten carbide is a composite of tungsten and carbon, bonded with cobalt or nickel. Its properties include:

أقصى صلابة → Resists wear from abrasive particles in seawater.

قوة ضغط عالية → Handles high pressures in desalination systems.

مقاومة التآكل → Protects against saltwater and brackish water corrosion.

الاستقرار الحراري → Performs well under temperature fluctuations.

عمر خدمة طويل → Reduces maintenance and replacement costs.

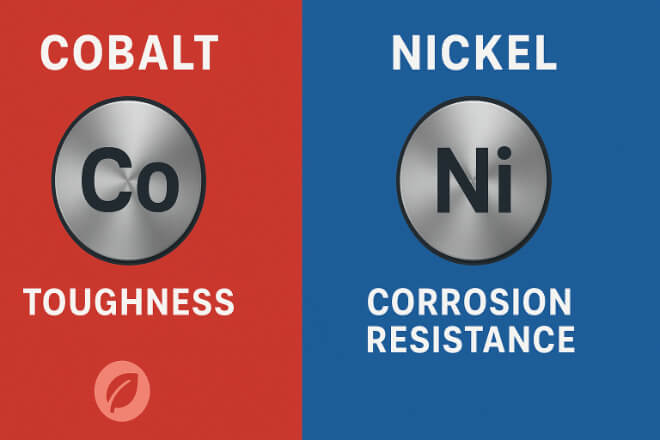

كربيد التنغستن المرتبط بالكوبالت مقابل كربيد التنغستن المرتبط بالنيكل

1) كربيد التنغستن المرتبط بالكوبالت

Offers higher صلابة for pumps exposed to vibration.

Used in systems where mechanical shock is a concern.

2) كربيد التنغستن المرتبط بالنيكل

أرقى مقاومة التآكل for high-salinity environments.

Best for coastal desalination plants and brackish water systems.

المزايا مقارنة بمواد الختم الأخرى

| ميزة | كربيد التنغستن | سيراميك | فُولاَذ |

|---|---|---|---|

| مقاومة التآكل | ممتاز للمواد الكاشطة | معتدل | فقير |

| مقاومة التآكل | عالية (درجات النيكل) | جيد جدًا | قليل |

| صلابة | عالية، تقاوم الصدمات | منخفض، هش | معتدل |

| Thermal Performance | ممتاز في درجات الحرارة العالية | جيد | معتدل |

| عمر الخدمة | طويلة الأمد | معتدل | قصير |

Applications in Desalination and Brackish Water Pumps

حلقات ختم كربيد التنغستن تستخدم في:

Reverse osmosis pumps → Provide reliable sealing under high pressure.

Intake and booster pumps → Handle seawater with abrasive particles.

Brackish water transfer systems → Prevent corrosion-related failures.

Energy recovery devices → Improve efficiency in desalination plants.

Marine-based desalination units → Operate reliably in offshore conditions.

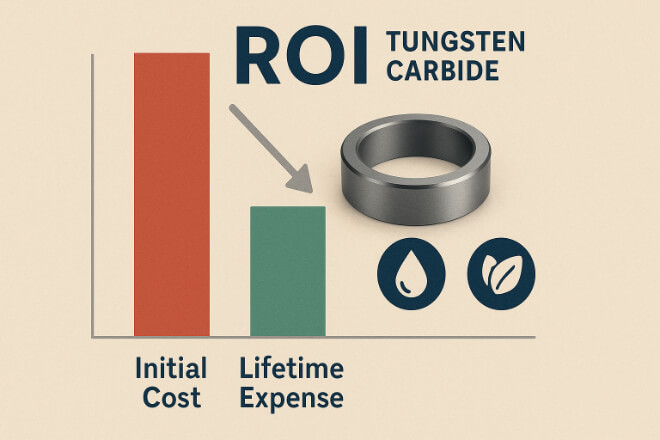

التكلفة مقابل القيمة طويلة الأجل

Although tungsten carbide seal rings may cost more upfront:

Reduce maintenance → Longer life means fewer replacements.

Improve ROI → Lower downtime increases production efficiency.

Protect equipment → Prevents costly damage to pumps and pipelines.

Support sustainability → Fewer replacements reduce waste and energy use.

الفوائد البيئية والسلامة

منع التسرب → Stops harmful saline discharge into the environment.

مواد قابلة لإعادة التدوير → Used rings can be recovered and reprocessed.

Energy savings → Efficient seals reduce energy consumption.

أفضل الممارسات لاستخدام حلقات ختم كربيد التنغستن

اختر المجلد المناسب → Nickel-bonded for high salinity, cobalt-bonded for vibration.

Inspect seals regularly → Detect wear before leaks occur.

تأكد من التثبيت الصحيح → Avoid misalignment and scratches.

العمل مع الموردين ذوي الخبرة → Guarantee material quality and accurate specs.

تخطيط جداول الصيانة → Reduce unplanned downtime.

أهم النقاط لصناع القرار

Tungsten carbide seal rings are ideal for desalination and brackish water pumps.

متانتها، مقاومة التآكل, and efficiency outperform ceramic or steel.

Higher upfront cost is offset by lower maintenance and downtime.

Using tungsten carbide supports environmental and operational goals.

خاتمة

Desalination and brackish water systems need seals that can handle salt, pressure, and abrasion.

Tungsten carbide seal rings deliver superior performance, reduce leaks, and improve pump life.

For decision-makers, investing in tungsten carbide ensures reliable water supply, cost savings, and environmental protection.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.