Tungsten carbide bushings are among the most durable components used in pumps, compressors, turbines, and industrial machinery.

هُم صلابة و مقاومة التآكل make them ideal for demanding environments.

However, even the toughest materials need proper maintenance to deliver long-term performance.

Regular inspection, correct lubrication, and suitable operating conditions can significantly extend the lifespan of tungsten carbide bushings — reducing equipment downtime and saving costs.

This article provides practical maintenance tips, explains common failure causes, and outlines a preventive maintenance plan to help you get the most out of your tungsten carbide bushings.

لماذا الصيانة مهمة

Even though tungsten carbide is extremely hard, it is also brittle. Improper handling, contamination, or excessive pressure can cause cracking or uneven wear.

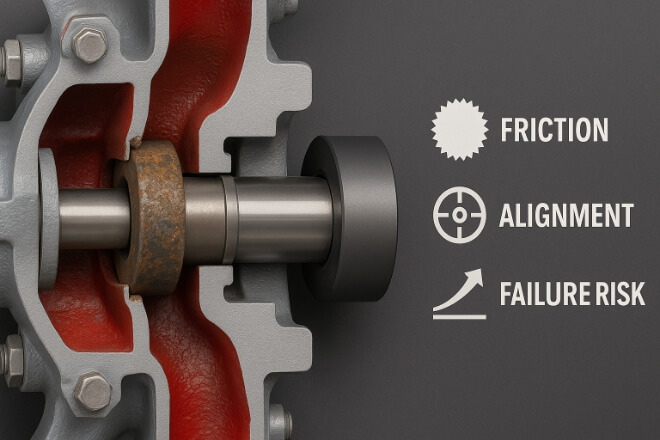

Without maintenance, bushings may:

Increase friction and energy use

Cause shaft misalignment or vibration

Lead to leakage or seal failure

Shorten overall equipment life

Preventive maintenance ensures that bushings perform reliably and remain within design tolerances for years.

Step 1: Keep Operating Conditions Stable

Tungsten carbide performs best under controlled and stable operating environments. Sudden changes in temperature, pressure, or load can stress the material.

| المعلمة | Recommended Range | لماذا هذا مهم |

|---|---|---|

| درجة حرارة التشغيل | Up to 500°C (varies by grade) | Avoids thermal expansion cracks |

| Pressure | Maintain design limits | Prevents deformation and leakage |

| Vibration | Minimize through balanced shafts | Reduces fatigue and microcracking |

| Contamination | None (filtered fluid only) | Prevents abrasive wear |

Stable operating conditions reduce mechanical stress and thermal cycling — both major contributors to early wear.

Step 2: Use Proper Lubrication

Lubrication is one of the most critical factors affecting bushing life.

An appropriate lubricant minimizes friction, removes heat, and prevents direct metal-to-carbide contact.

Use clean, filtered oil or compatible process fluid.

Avoid dry operation unless designed for it.

Monitor oil temperature and flow rate regularly.

If lubrication is insufficient, even tungsten carbide can experience scoring and surface polishing, which accelerates wear.

Step 3: Schedule Regular Inspections

Routine inspection helps detect early signs of wear or cracking before they lead to failure.

Bushings should be visually checked during every shutdown or maintenance cycle.

Inspection should focus on:

Surface roughness (Ra ≤ 0.05 µm for sealing applications)

Cracks or chips near edges

Polishing or groove marks on the bore

Dimension tolerance drift (especially inner diameter)

Step 4: Prevent Contamination

Abrasive particles are one of the top reasons bushings wear prematurely.

Always use clean lubricants and ensure the system has filtration and flushing capability.

| Contaminant Type | Source | Effect on Bushings |

|---|---|---|

| الجسيمات الكاشطة | Unfiltered process fluid or dust | Causes scratches and grooves |

| Corrosive chemicals | Chemical carryover or cleaning agents | Leaches binder, weakens carbide |

| Moisture ingress | Seal failure or humid air | Promotes corrosion and pitting |

Installing filters and maintaining clean pipelines drastically reduces abrasive and chemical attack, keeping bushings smooth and aligned.

Step 5: Control Installation and Fit

Even a high-quality bushing can fail early if installed incorrectly.

Always check press-fit tolerances, shaft alignment, and housing cleanliness before installation.

Over-tight fits can create tensile stress, while loose fits may allow micro-movement that leads to cracking.

When installing, use hydraulic or thermal fitting methods instead of hammering.

Step 6: Monitor Vibration and Load

Excessive vibration is a major cause of premature wear.

Monitor vibration levels in rotating equipment regularly using a vibration analyzer.

If high vibration is detected, inspect:

Shaft alignment

Bearing wear

Load balance

Coupling condition

By controlling load and vibration, the bushing surface remains evenly loaded, reducing fatigue failure.

Step 7: Implement a Maintenance Schedule

A structured preventive maintenance plan ensures consistency.

| Frequency | Maintenance Activity | غاية |

|---|---|---|

| Weekly | Check oil level, flow, and temperature | Ensure lubrication is consistent |

| Monthly | Inspect vibration and noise levels | Detect early imbalance or misalignment |

| Quarterly | Check bushing wear and surface condition | Identify early wear signs |

| Annually | Full inspection and dimensional measurement | Plan replacement if limits exceeded |

Following a preventive schedule helps forecast replacement needs before failures occur — improving uptime and productivity.

Step 8: Use the Right Grade for Your Environment

Different operating environments demand specific tungsten carbide grades.

على سبيل المثال:

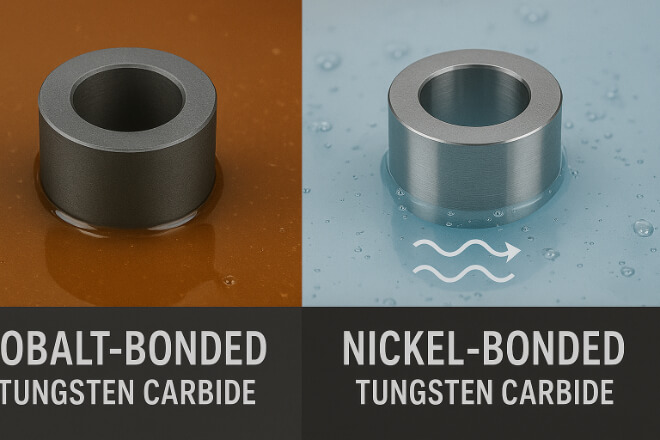

Cobalt-bonded grades (YG) — excellent مقاومة التآكل for general machinery.

Nickel-bonded grades (YN) — superior مقاومة التآكل for chemical or seawater use.

Fine-grain micro-carbides — better edge strength for high-precision parts.

Selecting the correct grade ensures that bushings maintain optimal performance and reduce maintenance frequency.

خاتمة

Tungsten carbide bushings can last for many years — but only with the right care.

By maintaining proper operating conditions, avoiding contamination, using the correct lubricant, and following a structured inspection routine, you can maximize their lifespan and reliability.

Investing in preventive maintenance not only saves money but also keeps your equipment operating efficiently and safely.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.