Centrifugal pumps are essential in industries such as water treatment, oil and gas, and chemicals. The pump shaft, which rotates at high speeds, is prone to wear.

Tungsten carbide bushings offer an ideal solution for these shafts, providing durability, مقاومة التآكل, and performance in harsh conditions.

In this article, we will explore why tungsten carbide bushings are the go-to choice for centrifugal pump shafts.

What Are Tungsten Carbide Bushings?

Tungsten carbide bushings are components made from a combination of tungsten and carbon.

معروفون بـ صلابة and durability, these bushings are used to reduce friction and wear between moving parts, making them ideal for centrifugal pumps.

The material’s strength allows it to perform well under high stress and abrasive conditions.

Why Tungsten Carbide Bushings Are Ideal for Centrifugal Pump Shafts

Centrifugal pumps face continuous friction and wear due to the rotation of the pump shaft. Tungsten carbide bushings offer the following benefits:

مقاومة التآكل: Tungsten carbide is highly resistant to wear, making it suitable for pumps exposed to abrasive materials and high-speed operations.

مقاومة التآكل: The material resists corrosion in harsh environments, including chemical exposure in industries like oil and gas.

High-Temperature Stability: Tungsten carbide maintains its properties even at elevated temperatures, ensuring the longevity of the pump.

Example: In the النفط والغاز sector, tungsten carbide bushings help prevent wear and corrosion in pumps handling abrasive and corrosive fluids.

Benefits of Using Tungsten Carbide Bushings for Centrifugal Pump Shafts

Using بطانات كربيد التنغستن in centrifugal pump shafts offers several advantages:

Longer Service Life: Tungsten carbide bushings can extend the life of pump shafts by reducing wear and preventing common issues like scoring.

Reduced Maintenance Costs: With less frequent replacement, tungsten carbide bushings reduce maintenance costs, making them a cost-effective choice.

Improved Pump Efficiency: These bushings reduce friction, allowing the pump to operate more efficiently and consume less energy.

Applications of Tungsten Carbide Bushings in Centrifugal Pumps

Tungsten carbide bushings are used in various industries where centrifugal pumps operate under extreme conditions:

Water Treatment: Protects pump shafts from wear in water treatment facilities.

النفط والغاز: Used in pumps that handle abrasive and corrosive fluids.

Chemical Processing: Prevents corrosion and wear in chemical plants.

التعدين: Extends the life of pumps used in mining operations.

How Tungsten Carbide Bushings Improve Pump Efficiency

Tungsten carbide bushings contribute to better pump performance by:

Reducing Friction: By minimizing friction, they lower energy consumption and improve the pump’s overall efficiency.

Minimizing Wear: Their مقاومة التآكل ensures that the pump runs smoothly for longer periods, reducing the risk of operational interruptions.

Preventing Misalignment: Tungsten carbide’s durability ensures that the pump shaft stays aligned, preventing costly maintenance issues.

Challenges and Considerations

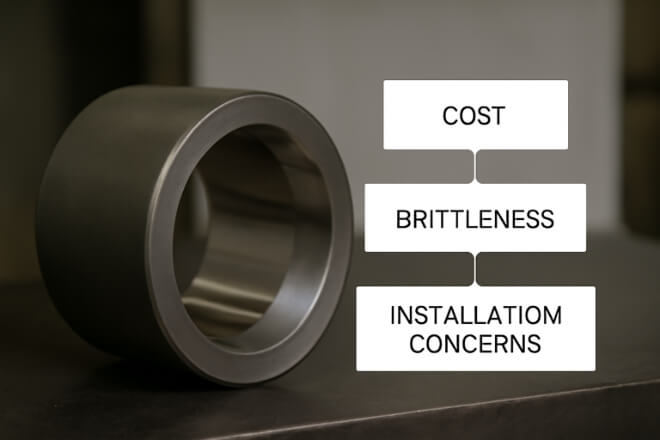

While tungsten carbide bushings offer many benefits, there are considerations to keep in mind:

Cost: Tungsten carbide bushings are more expensive than other materials, though the long-term savings in maintenance and downtime often justify the investment.

Brittleness: While extremely hard, tungsten carbide can be brittle, so proper handling during installation is essential.

خاتمة

Tungsten carbide bushings are an excellent choice for centrifugal pump shafts due to their wear resistance, durability, and performance in harsh conditions.

While they come with a higher initial cost, the long-term benefits such as extended service life, reduced maintenance, and improved efficiency make them a valuable investment for industries that rely on centrifugal pumps.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.