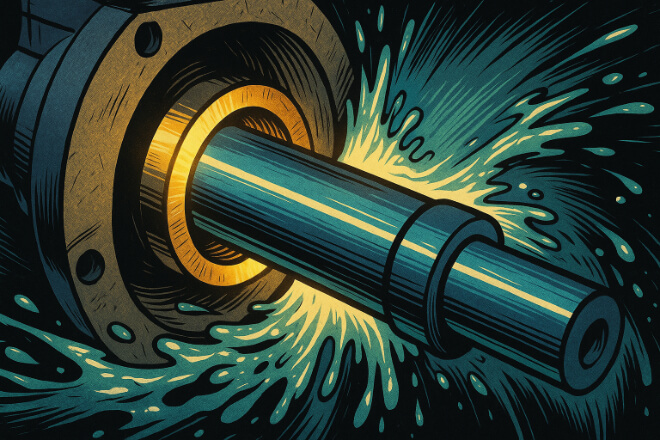

Desalination plants and seawater intake stations operate in some of the toughest environments in the world.

Pumps in these systems must handle constant exposure to seawater, sand, silt, and corrosive ions. To keep these pumps running reliably, many engineers choose tungsten carbide bushings.

This article explains why tungsten carbide is widely used in desalination, what grades work best, how it handles seawater corrosion, and what OEMs and plant operators should look for when selecting bushings.

Why Seawater Pumps Need High-Performance Bushings

Desalination systems and seawater intake lines run at high load, high flow, and long operating hours. Pump bushings must survive:

Continuous saltwater exposure

Sand and silt abrasion

High rotational speed

Corrosion from chloride ions

Vibration and misalignment

Start-stop cycles

Traditional materials like bronze or stainless steel often fail early because seawater is aggressive. It contains:

Chlorides, which attack metals

Sand and debris, causing abrasive wear

Microorganisms, leading to bio-corrosion

High dissolved oxygen, accelerating pitting

Tungsten carbide bushings solve these challenges because they combine مقاومة التآكل, abrasion resistance, and high hardness.

Key Performance Benefits of Tungsten Carbide in Seawater Systems

Tungsten carbide bushings offer unique advantages in desalination plants and seawater intake pumps.

Main benefits

أقصى مقاومة التآكل against sand, silt, and solids

Strong مقاومة التآكل, especially with nickel binder grades

Dimensional stability even under temperature changes

Long operating life, reducing pump downtime

Lower maintenance cost for operators

High compressive strength, preventing deformation

These benefits are essential for seawater systems where pumps run 24/7.

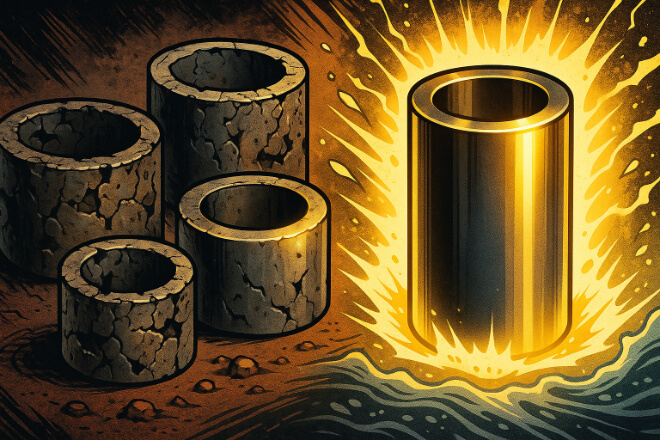

WC-Ni vs WC-Co: Choosing the Right Binder for Seawater

The binder type used in tungsten carbide bushings determines how well they resist seawater corrosion.

Desalination plants typically choose between WC-Ni and WC-Co.

1). Binder Comparison Table

| نوع المجلد | مقاومة التآكل | مقاومة التآكل | Recommended Application |

|---|---|---|---|

| WC-Co (Cobalt Binder) | واسطة | عالية جدًا | Abrasive water with low corrosion |

| WC-Ni (Nickel Binder) | عالية جدًا | عالية جدًا | Seawater, brine, desalination plants |

2). Why WC-Ni is preferred for desalination

Nickel resists chloride attack

Very low corrosion rate

Less binder leaching

Best choice for RO (Reverse Osmosis) and MSF (Multi-Stage Flash) plants

WC-Co is still useful where abrasion is severe, but corrosion risk must be evaluated.

How Tungsten Carbide Handles Saltwater Corrosion

Seawater corrosion is mainly caused by chloride ions, which attack metals and weaken them over time.

Tungsten carbide offers strong protection because:

WC grains are chemically inert

Nickel binder forms a more stable passive layer

Dense microstructure blocks water penetration

قليل المسامية prevents pitting

High hardness protects against erosive wear

1). Corrosion Behavior Table

| مادة | Pitting Resistance | Chloride Resistance | Expected Lifespan |

|---|---|---|---|

| Stainless Steel 316 | واسطة | واسطة | 6–18 months |

| Duplex Steel | عالي | عالي | 12–36 months |

| WC-Co | عالي | عالي | 3–5 years |

| WC-Ni | عالية جدًا | عالية جدًا | 5–10 years |

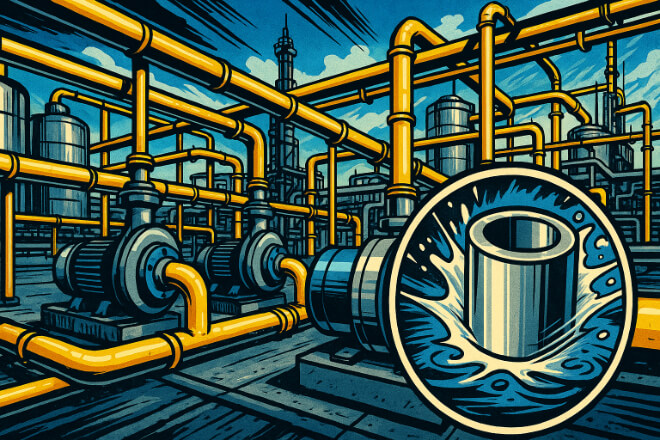

Where Tungsten Carbide Bushings Are Used in Desalination Plants

Desalination systems use several types of pumps. Tungsten carbide bushings are installed in:

1). Desalination pump types

High-pressure RO pumps

Booster pumps

Vertical sump seawater intake pumps

Brine recirculation pumps

Energy recovery pumps

Intake lift pumps

Pretreatment stage pumps

2). Functional roles of bushings

Shaft support

Reducing vibration

Preventing shaft run-out

Maintaining alignment

Minimizing wear on rotating parts

In all these roles, tungsten carbide provides long-term stability even with constant seawater exposure.

Common Failure Modes in Seawater Conditions

Even with strong materials, seawater can still cause failures.

1). Typical failure types

Binder leaching, especially in cobalt grades

Abrasive wear from sand and shells

Pitting corrosion when المسامية is high

Misalignment wear from pump vibration

Thermal shock cracking during rapid temperature changes

2). Simple ways to prevent failure

Choose WC-Ni for seawater

Ensure proper filtration to reduce sand

Maintain shaft alignment

Use high-كثافة, HIP-sintered carbide

Inspect bushings during pump overhauls

Proper selection and maintenance can extend service life by years.

How to Choose the Right Supplier for Seawater Applications

Choosing the right supplier is critical for seawater pump reliability.

Important supplier capabilities

Experience in desalination industry

Ability to supply WC-Ni grades

HIP sintering for highest density

Corrosion testing capability

Fast lead times for replacement parts

OEM customization

A strong supplier ensures stable performance and reduces equipment downtime.

خاتمة

Tungsten carbide bushings are essential components in desalination and seawater intake pumps.

Their corrosion resistance, abrasion performance, and long service life make them the best option for operators who need reliability in harsh saltwater environments.

By choosing the right binder, maintaining proper pump conditions, and working with expert suppliers, plants can operate more efficiently and reduce maintenance costs.

إذا كنت تريد معرفة المزيد من التفاصيل حول أي شركة، فلا تتردد في اتصل بنا.